Oil-in-water type pest repellent composition

An oil-in-water, pest repellent technology, applied in the fields of pest control, pest repellent, animal repellent, etc., can solve problems such as insufficient pest repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0275] Hereinafter, although an Example demonstrates this invention, this invention is not limited to the range of an Example. In addition, in this Example, various measurements and evaluations were performed by the following methods.

[0276] (Surface Tension of Liquid Oily Components)

[0277]The surface tension of the liquid oily component is a surface tension measured in an environment of 25°C by the Wilhelmy method using a platinum plate using an automatic surface tensiometer Tensiometer K100 (KRUSS).

[0278] (Viscosity of liquid oily components)

[0279] As the B-type rotational viscometer based on JIS K7117-1:1999, Toki Sangyo Co., Ltd.'s Viscometer TVB-10 was used. It is difficult to accurately measure all the components to be measured under one measurement condition because the viscosity value of each sample varies greatly. Therefore, measurement was performed using two types of rotors. Regarding the viscosity, first, the spindle M2 was used, and the measurement ...

manufacture example 1

[0320] Production example 1 (production of dimethyl silylated cellulose particles (B10))

[0321] Weigh 100.00 g of cellulose particles CELLULOBEADS D-30 (Dadong Chemical Industry Co., Ltd., 30 μm spherical cellulose) in a water content meter and place it in a 2000 mL separable flask. Heat and vacuum-dry until the final moisture value becomes 1% by mass or less. Add 600 mL of super-dehydrated N,N-dimethylformamide (Fujifilm Wako Pure Chemical Industries, Ltd.) into a 2000 mL separable flask filled with dried cellulose particles, stir at room temperature for 30 minutes, and slowly 10.00 g of chlorodimethylsilane (Tokyo Chemical Industry Co., Ltd.) was added dropwise. After completion|finish of dripping, internal temperature was heated up to 80 degreeC with the water bath, and it was made to react for 4 hours. After the reaction, the reaction solution was separated by filtration, and the filtrate was washed with acetone. Thereafter, the filtrate was heated and vacuum-dried at...

Embodiment 1~57

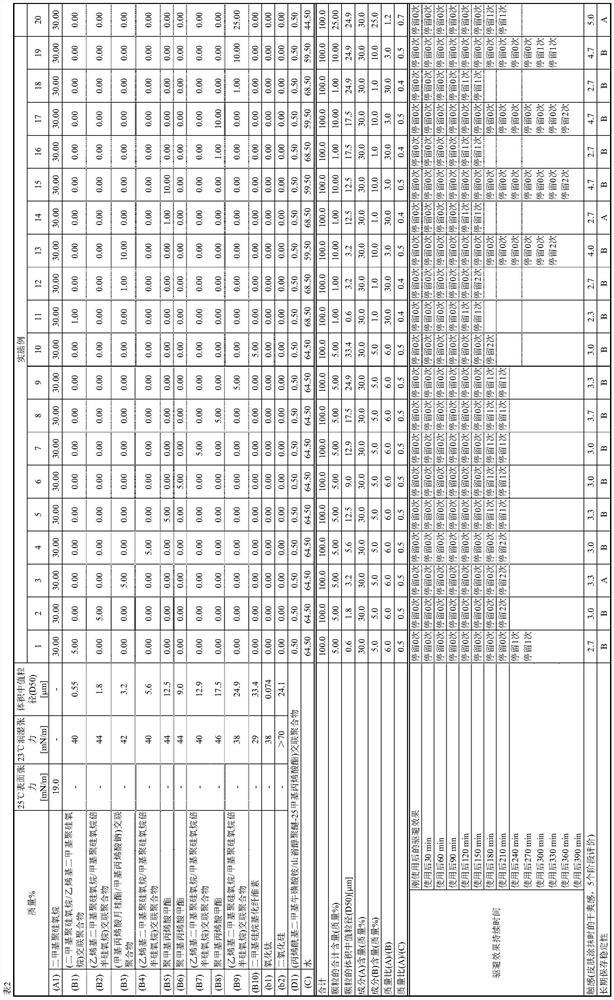

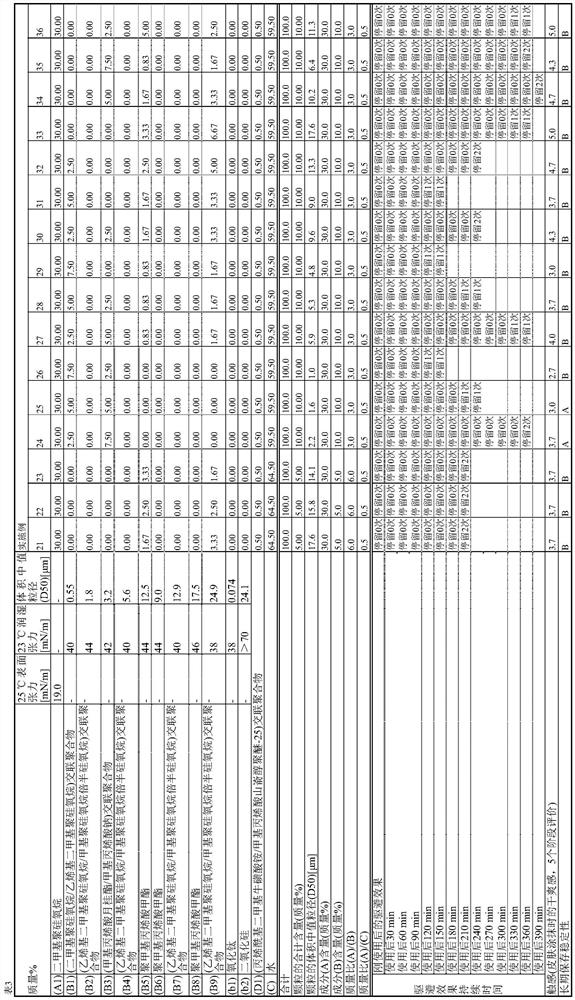

[0324] Examples 1-57, Comparative Examples 1-12 (production and evaluation of compositions)

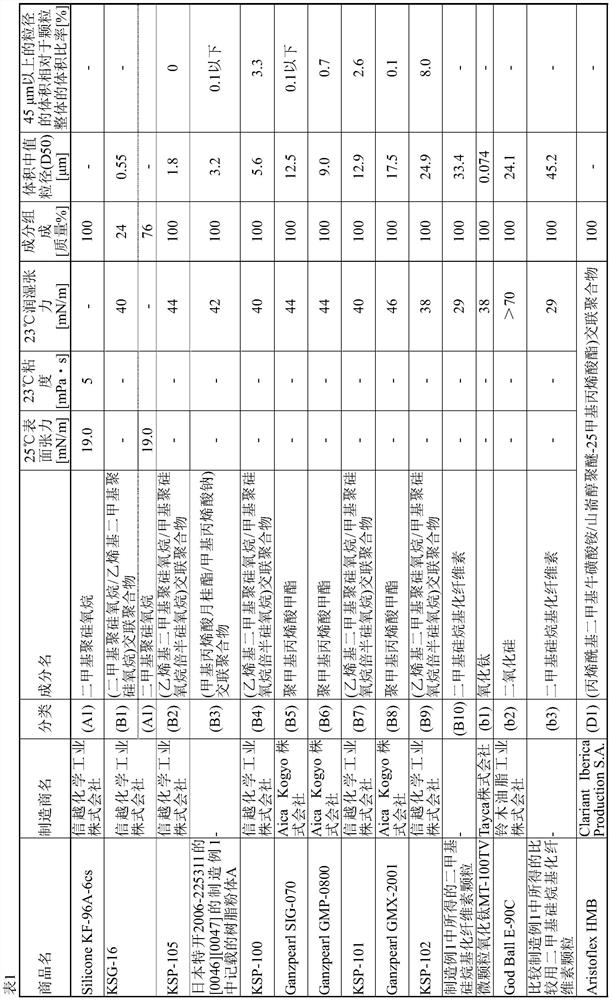

[0325] The oil-in-water composition is obtained by the following procedure: Among the components shown in Tables 2 to 4 and Tables 6 to 7, the granular components and water are prepared in advance, and the T.K. Partly replaced with T.K.HOMO DISPER 2.5 type, after mixing, the ingredients (A) and (a) and thickeners in the amounts shown in the table were prepared, and T.K.ROBOMIX (Tokuki Kagaku ) was replaced by a device made of T.K.HOMOMIXER MARK II 2.5, and stirred at 8000rpm for 2 minutes. The descriptions of (A) to (D) described in the table correspond to the components (A) to (D) in this specification, respectively, and the descriptions of (a) and (b) correspond to the range of component (A) in this specification, respectively. Particles outside the range of the liquid oily component and the component (B) correspond. Moreover, the components used in Tables 2-4 are shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com