Method for synthesizing diisobutylamine, catalyst and catalyst preparation method

A technology of diisobutylamine and catalyst is applied in the field of chemical industry to achieve the effects of high activity, reduction of preparation cost and process requirements, and reduction of roasting temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention discloses a catalyst for synthesizing diisobutylamine, and the catalyst is used in the synthesis method of synthesizing diisobutylamine through amination reaction of isobutanol. The mass percent composition of the catalyst is as follows: 15% of cobalt salt active component, 0.5% of hydrophilic nano material modifier, and 84.5% of alumina carrier.

[0026] The preparation method of the catalyst is a two-step impregnation method.

[0027] The steps of a kind of preparation method of present embodiment catalyst are as follows:

[0028] Step 1, according to the mass of the catalyst to be prepared, weigh cobalt salt with a mass percentage of 15%, disperse and dissolve it in deionized water, stir it evenly, and prepare an impregnating solution;

[0029] Step 2, impregnate the prepared impregnating solution and the activated alumina carrier with a mass percentage of 84.5% of the catalyst to be prepared according to the equal volume impregnation method, and impre...

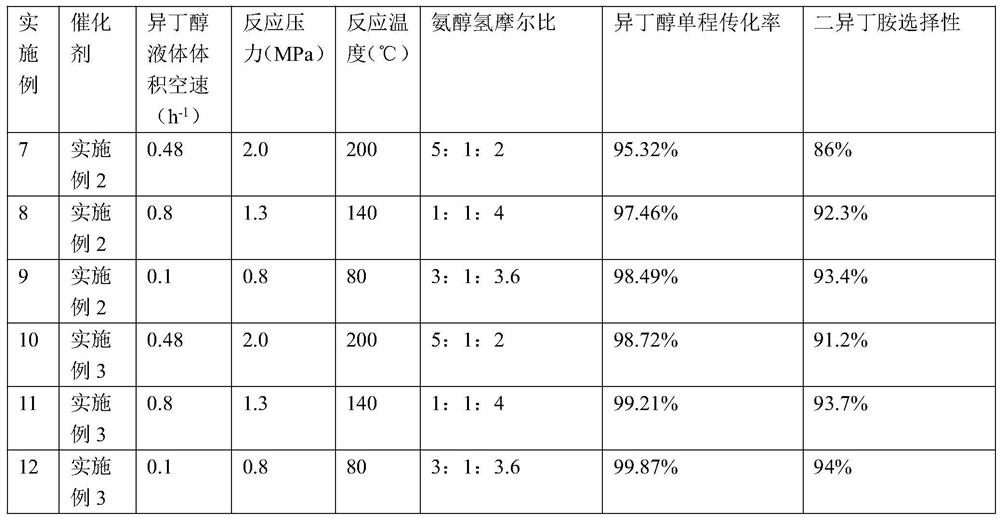

Embodiment 2

[0043] The invention discloses a catalyst for synthesizing diisobutylamine, and the catalyst is used in the synthesis method of synthesizing diisobutylamine through amination reaction of isobutanol. The mass percent composition of the catalyst is: 45% of cobalt salt active component, 10% of hydrophilic nano material modifier, and 45% of alumina carrier.

[0044] The preparation method of the catalyst is a two-step impregnation method.

[0045] The steps of a kind of preparation method of present embodiment catalyst are as follows:

[0046] Step 1, according to the mass of the catalyst to be prepared, weigh 45% by mass of cobalt salt, disperse and dissolve it in deionized water, stir it evenly, and prepare an impregnating solution;

[0047] Step 2, impregnate the prepared impregnating solution and the active alumina carrier with a mass percentage of 45% of the mass of the catalyst to be prepared according to the equal volume impregnation method, and impregnate at 60°C for 5 ho...

Embodiment 3

[0061] The invention discloses a catalyst for synthesizing diisobutylamine, and the catalyst is used in the synthesis method of synthesizing diisobutylamine through amination reaction of isobutanol. The mass percent composition of the catalyst is: 30% of cobalt salt active component, 7% of hydrophilic nano material modifier, and 63% of alumina carrier.

[0062] The preparation method of the catalyst is a two-step impregnation method.

[0063] The steps of a kind of preparation method of present embodiment catalyst are as follows:

[0064] Step 1, according to the mass of the catalyst to be prepared, weigh 30% by mass of cobalt salt, disperse and dissolve it in deionized water, stir it evenly, and prepare an impregnating solution;

[0065] Step 2, impregnate the prepared impregnating solution and the active alumina carrier with a mass percentage of 63% of the catalyst to be prepared according to the equal volume impregnation method, and impregnate at 60°C for 5 hours, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com