Continuous pressing seat assembly taking and transferring device for automatic production of flusher

A technology of automatic production and transfer device, applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of liquid leakage at the liquid outlet, prone to accidental touch, and restricting production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated by the following examples.

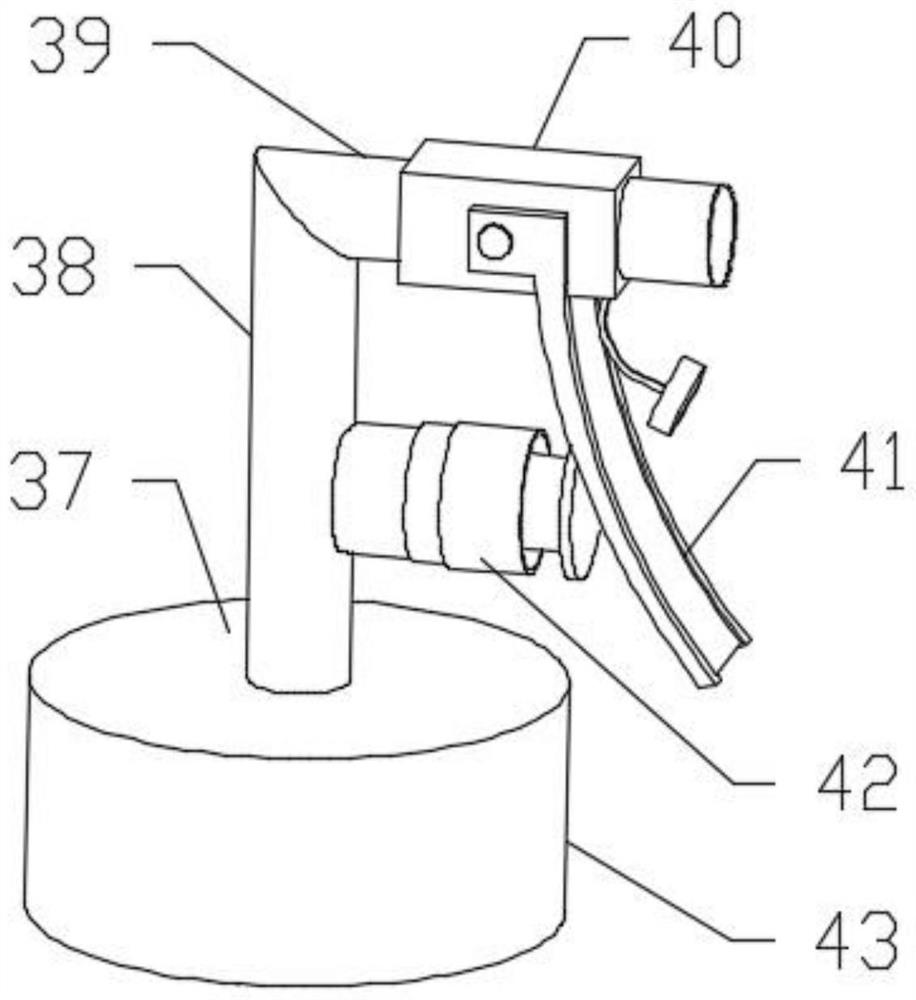

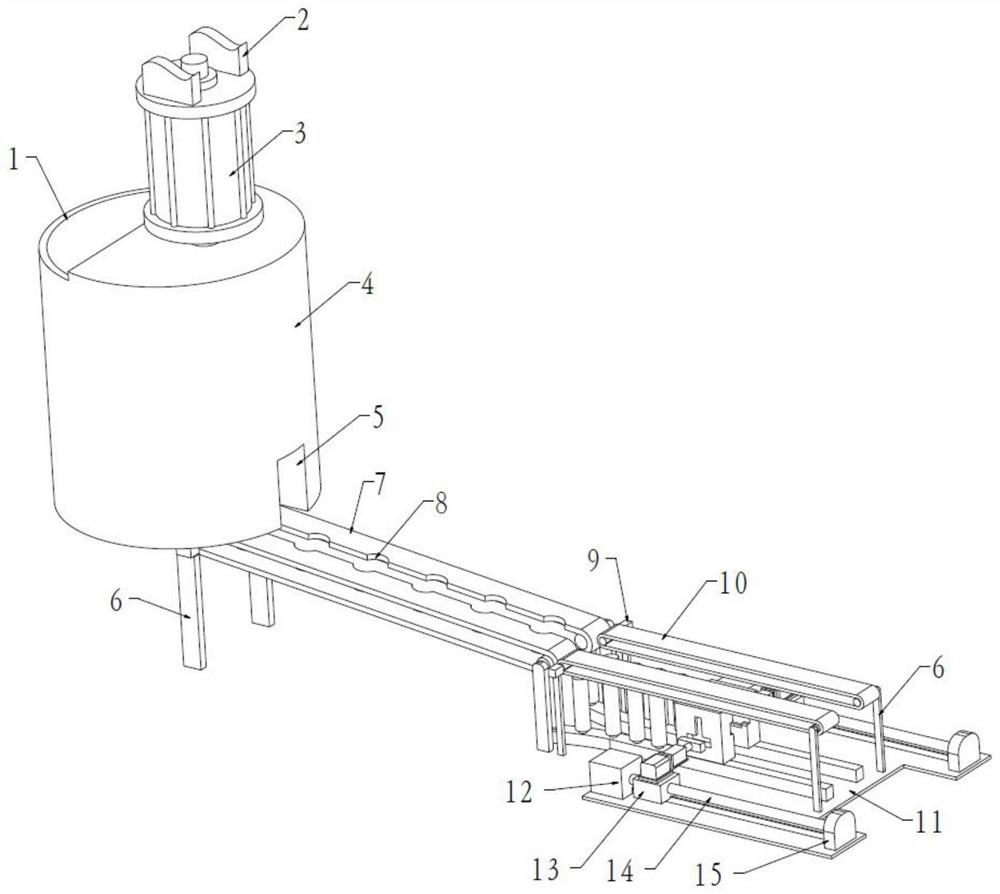

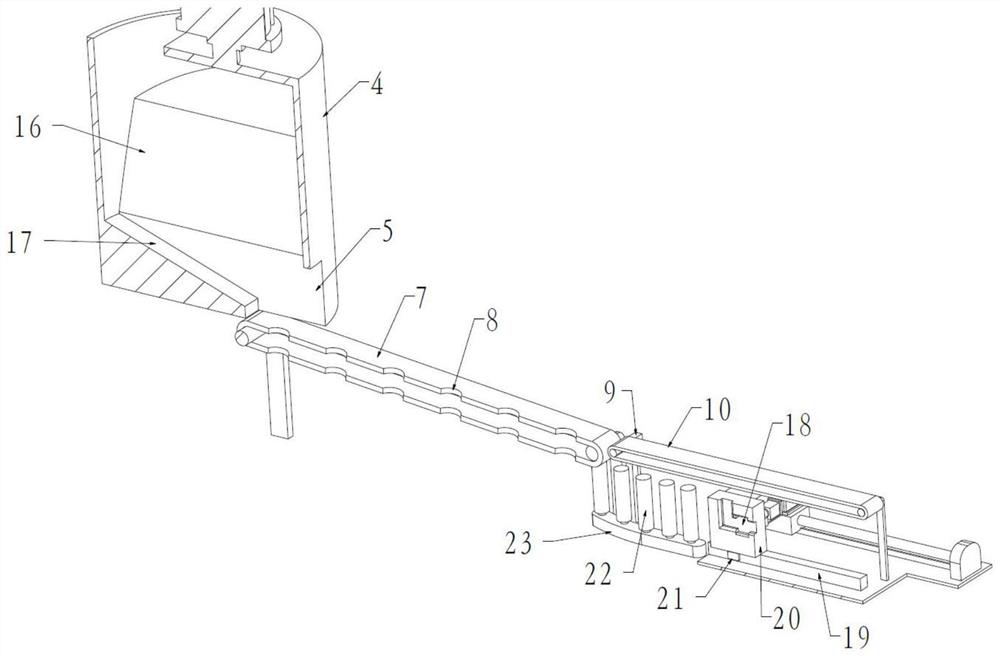

[0036] The continuous feeding and transferring device of the pressing seat assembly for the automatic production of the washer, including the storage tank 4, the storage tank 4 is connected to the first conveyor belt 7, the first conveyor belt 7 is connected to the second conveyor belt 10, and the second conveyor belt Tube type linear motors 12 are arranged on both sides below 10, a vertical vibrating motor 3 is connected to the top cover plate of the storage tank 4, a feed inlet 1 is provided on the top of the storage tank 4, and a side wall and a side of the bottom plate are provided with The strip-shaped hole-shaped discharge port 5, the first conveyor belt 7 below the storage tank 4 is inclined, and the first conveyor belt 7 and the second conveyor belt 10 are all arranged in pairs and the conveyor belts on both sides are in the middle There is a gap, the pressing seat assembly 37 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com