Preparation method of Ti4O7 anode loaded with graphene nanoparticles

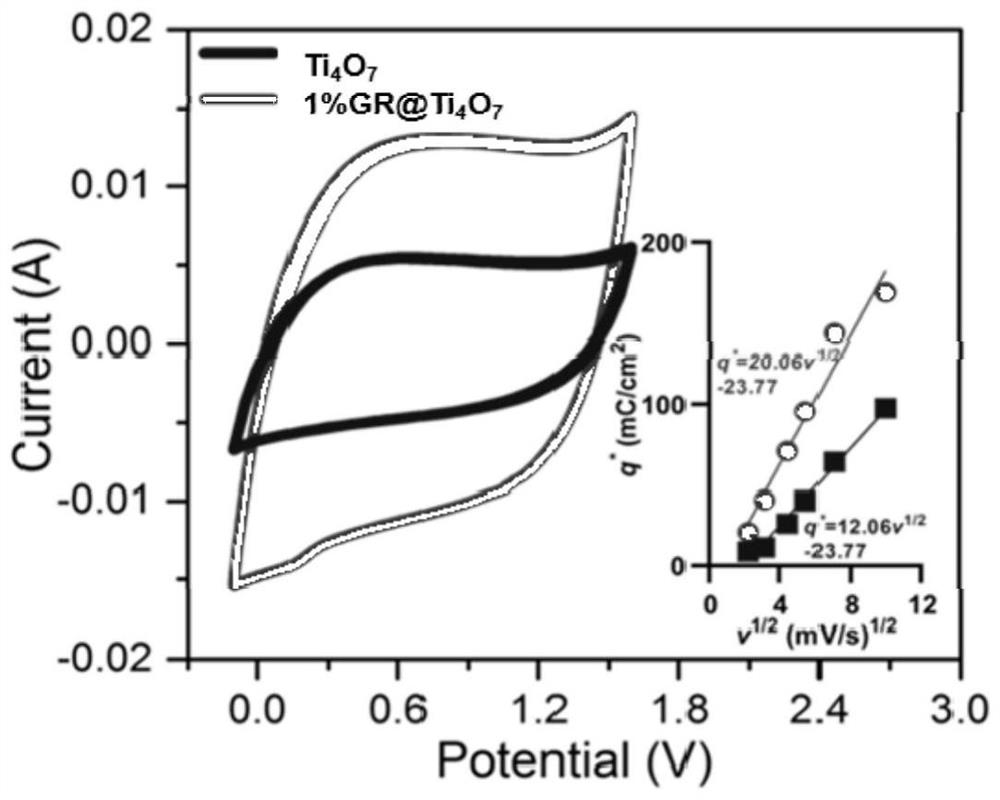

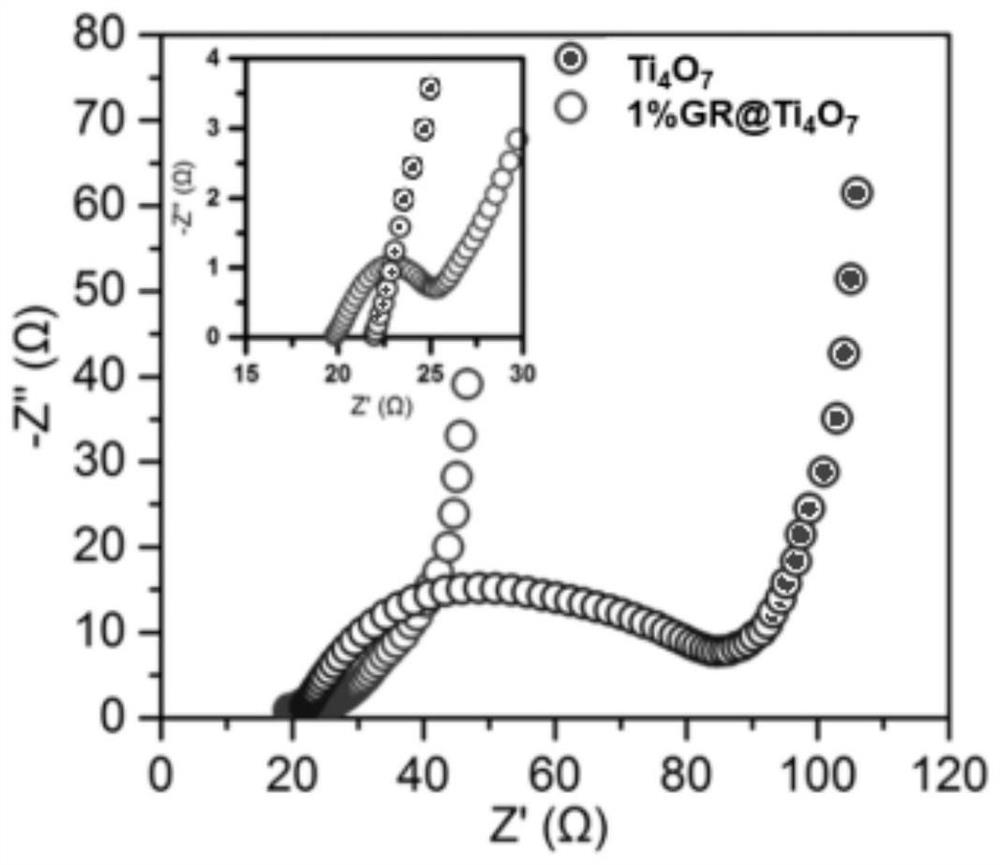

A nanoparticle and graphene technology, applied in the field of electrochemistry, can solve the problems of general catalytic activity, low yield of hydroxyl radicals, and high internal resistance of charge transfer, and achieve the goal of improving catalytic activity, reducing internal resistance of charge transfer, and increasing production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

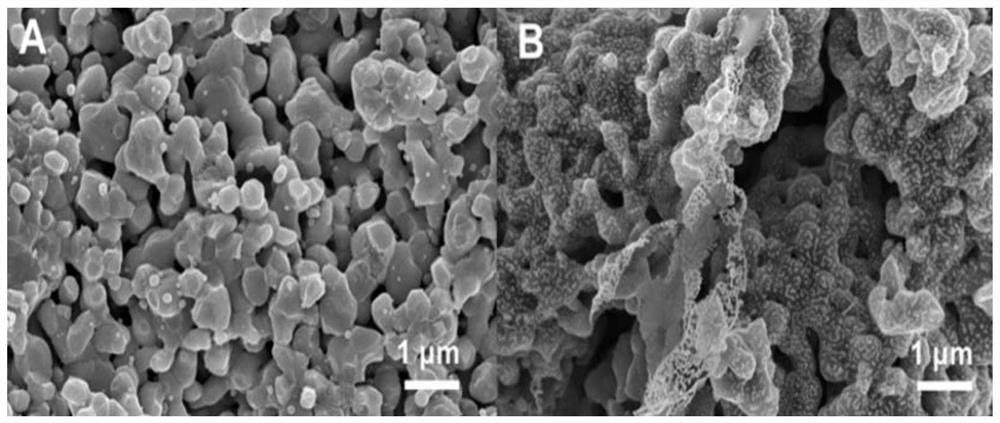

[0029] Take Ti 4 o 7 Powder, graphene nanoparticles, ceria powder mixed, where Ti 4 o 7 The diameter of powder is 100nm, ball milling is uniform, and mixed powder is obtained, wherein the mass fraction of graphene nanoparticles is 1%, the mass fraction of cerium oxide powder is 8%, ball milling process is: 1800r / min, ball milling time 20min; Wherein Graphene nanoparticles are graphene oxide;

[0030] Sintering is carried out under high temperature and high pressure by spark plasma sintering. The sintering process is as follows: sintering heating rate 55°C / min, maximum sintering temperature 1200°C, pressure 3MPa, sintering time 20min, and the anode is obtained.

Embodiment 2

[0032] Take Ti 4 o 7 Powder, graphene nanoparticles, ceria powder mixed, where Ti 4 o 7 The diameter of powder is 500nm, ball milling is uniform, and mixed powder is obtained, wherein the mass fraction of graphene nanoparticles is 3%, the mass fraction of cerium dioxide powder is 7%, ball milling process is: 1650r / min, ball milling time 30min; Wherein Graphene nanoparticles are reduced graphene;

[0033] Sintering is carried out under high temperature and high pressure by spark plasma sintering. The sintering process is as follows: sintering heating rate 60°C / min, sintering temperature 1250°C, pressure 4MPa, sintering time 25min, and the anode is obtained.

Embodiment 3

[0035] Take Ti 4 o 7 Powder, graphene nanoparticles, ceria powder mixed, where Ti 4 o 7 The diameter of the powder is 1um, and the ball mill is uniform to obtain a mixed powder, wherein the mass fraction of graphene nanoparticles is 4%, and the mass fraction of ceria powder is 6%. The ball milling process is: 1500r / min, and the ball milling time is 40min;

[0036]Sintering is carried out under high temperature and high pressure by spark plasma sintering. The sintering process is as follows: sintering heating rate 60°C / min, sintering temperature 1100°C, pressure 1MPa, sintering time 20min, and the anode is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com