Waterproof ceramic tile adhesive integrating interface treatment, waterproofing and bonding

A technology of interface treatment and tile adhesive, which is applied in the field of waterproof tile adhesive, can solve the problems of multiple construction procedures, long construction period, and high cost of materials, and achieve the effects of reducing water absorption, improving compactness and strength, and eliminating large air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiment:

[0016] 1. Preparation of waterproof tile adhesive integrating interface treatment, waterproofing and bonding

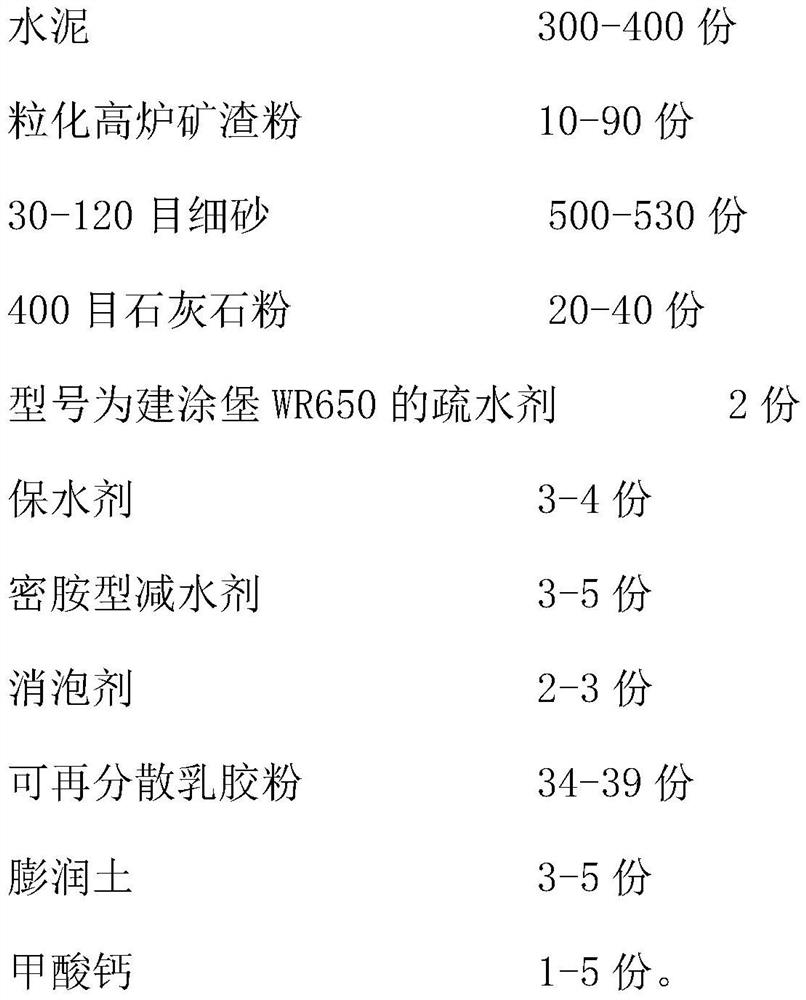

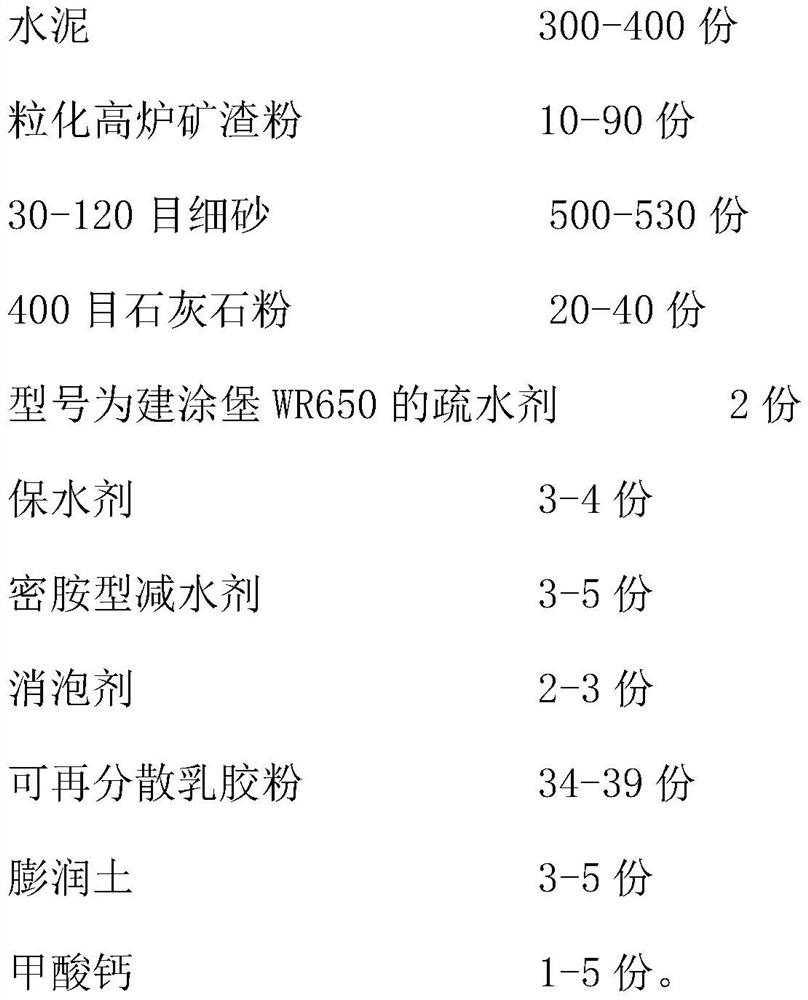

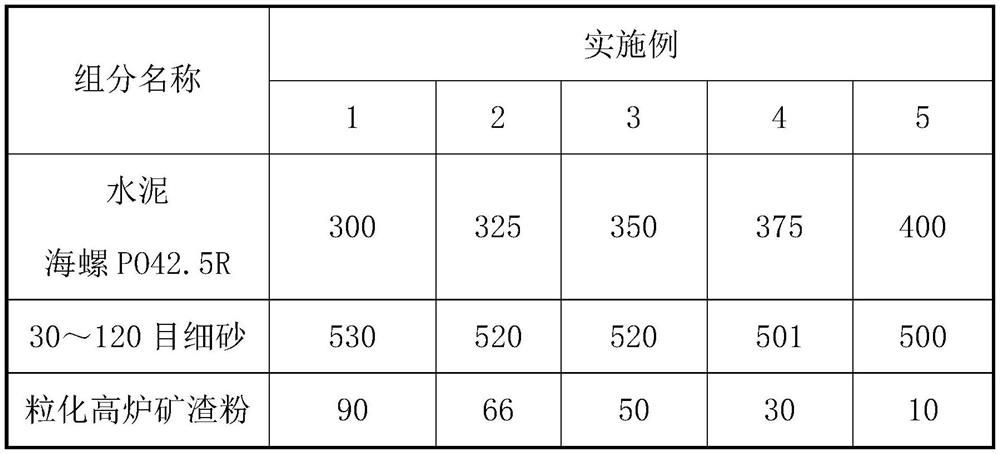

[0017] The parts by weight of each component of embodiments 1 to 5 are shown in the table below:

[0018]

[0019]

[0020] 2. Relevant experimental tests and data

[0021] 2.1 Examples 1 to 5 Waterproof tile adhesive (mixture ratio of powder and water is 1:0.2) as a special interface mortar test test is as follows:

[0022]

[0023]

[0024] The above-mentioned waterproof tile adhesive mixing and curing methods are as follows:

[0025] 1. When testing according to JGJ / T 70-2009, use a mixer conforming to JG / T 3033, first drain the water and then discharge the material, stir for 120s, stop for 5min (scrape off the stirring blade and the slurry on the wall of the pot at the same time), and then stir for 120s.

[0026] 2. When testing according to JC / T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com