Cashew nut oil modified bisphenol A phenolic resin and preparation method thereof

A technology of phenolic resin and cashew nut oil, applied in the field of phenolic resin, can solve problems affecting product processing and product quality, poor compatibility of phenolic resin, easy aging of tire rubber, etc., achieve good mechanical strength, good anti-aging performance, prevent resin The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

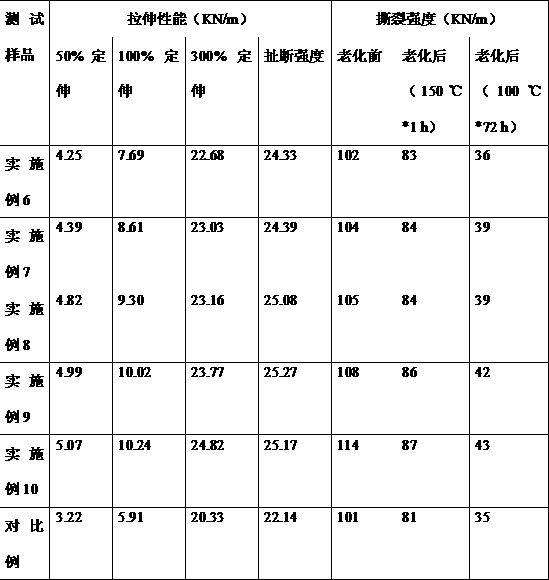

Examples

Embodiment 1

[0032] A cashew nut oil modified bisphenol A phenolic resin, consisting of the following raw materials: 84kg of bisphenol A, 65kg of formaldehyde solution, 12kg of cashew nut oil, 27kg of polysiloxane imide copolymer, 2kg of nano-titanium dioxide, 1kg of carbon nanotubes, Organic acid 0.5kg;

[0033] The organic acid is oxalic acid;

[0034] The mass concentration of the aqueous formaldehyde solution is 30%;

[0035] Wherein, polysiloxane imide copolymer is prepared according to the following method:

[0036] Add styrene, maleic anhydride and 1,3-butadiene to toluene to obtain a reaction solution. Under the protection of nitrogen, start stirring, raise the temperature of the reaction solution to 60~65°C, add the initiator dropwise, and control the reaction solution The temperature of the solution is 60~70°C, after the dropwise addition, the temperature is raised to 90°C, and the reaction is stirred for 6 hours, then the temperature of the reaction solution is lowered to 20°C...

Embodiment 2

[0041] A cashew nut oil modified bisphenol A phenolic resin, consisting of the following raw materials: 105kg of bisphenol A, 80kg of formaldehyde solution, 15kg of cashew nut oil, 35kg of polysiloxane imide copolymer, 5kg of nano-titanium dioxide, 3kg of carbon nanotubes, Organic acid 1.2kg;

[0042] The organic acid is acetic acid;

[0043] The mass concentration of the aqueous formaldehyde solution is 40%;

[0044] Wherein, polysiloxane imide copolymer is prepared according to the following method:

[0045] Add styrene, maleic anhydride and 1,3-butadiene to toluene to obtain a reaction solution. Under the protection of nitrogen, start stirring, raise the temperature of the reaction solution to 60~65°C, add the initiator dropwise, and control the reaction solution The temperature of the solution is 70~80°C, after the dropwise addition, the temperature is raised to 100°C, and the reaction is stirred for 3 hours, then the temperature of the reaction solution is lowered to 30...

Embodiment 3

[0050] A cashew nut oil modified bisphenol A phenolic resin, consisting of the following raw materials: 90kg of bisphenol A, 70kg of formaldehyde solution, 13kg of cashew nut oil, 30kg of polysiloxane imide copolymer, 4kg of nano-titanium dioxide, and 1.5kg of carbon nanotubes , organic acid 0.6kg;

[0051] The organic acid is oxalic acid;

[0052] The mass concentration of the aqueous formaldehyde solution is 37%;

[0053] The particle size of the nano-titanium dioxide is 15-50nm;

[0054] Wherein, polysiloxane imide copolymer is prepared according to the following method:

[0055] Add styrene, maleic anhydride and 1,3-butadiene to toluene to obtain a reaction solution. Under the protection of nitrogen, start stirring, raise the temperature of the reaction solution to 60~65°C, add the initiator dropwise, and control the reaction solution The temperature of the solution is 65~75°C, after the dropwise addition, the temperature is raised to 95°C, and the reaction is stirred f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com