Low-activation refractory medium-entropy alloy and preparation method thereof

An entropy alloy, low activation technology, applied in the field of metal materials, can solve the problems of damage to the toughness of multi-component alloys, and achieve the effects of excellent processing performance, good toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

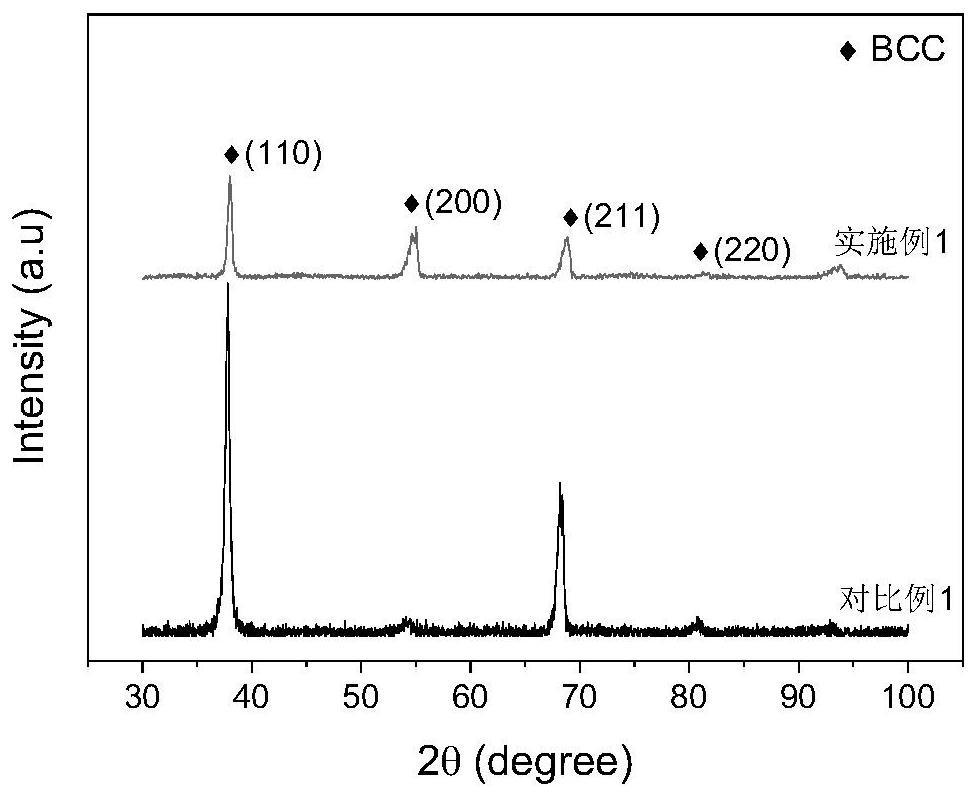

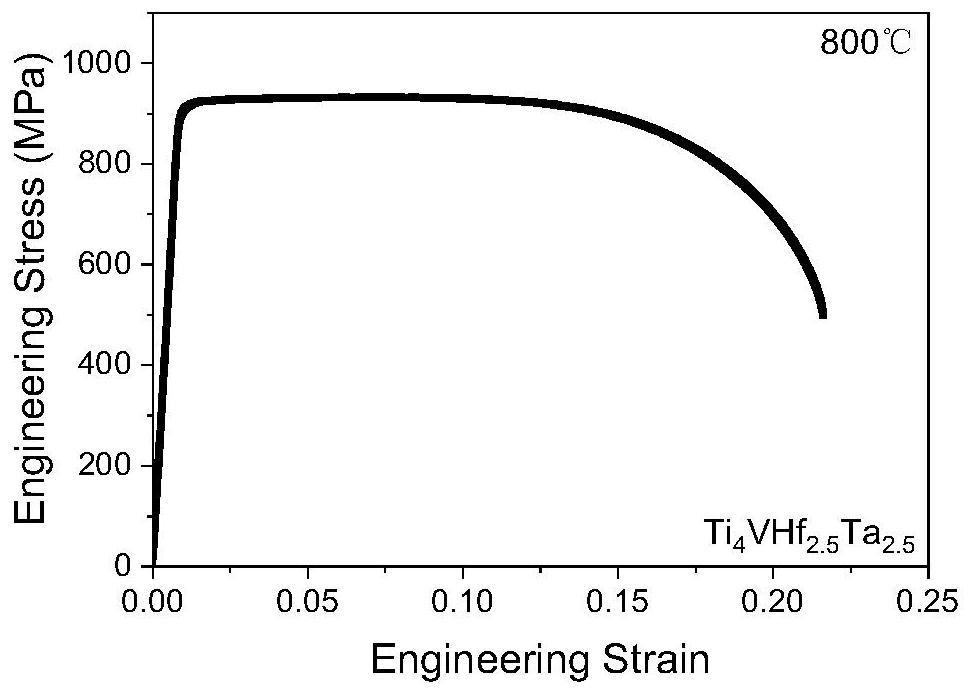

[0038] Low activation refractory Ti 4 wxya 2.5 Ta 2.5 The preparation steps of medium entropy alloy are as follows:

[0039] (1) According to the required alloy atomic ratio, select the corresponding quality of pure Ti, pure V, pure Hf and pure Ta to configure as raw materials, the specific content is 40at.%Ti, 10at.%V, 25at.%Hf and 25at. %Ta. First put Ti and Ta, V and Hf together to prepare the master alloy by arc melting, and then put the master alloy together and use arc melting to form an ingot. During the smelting process, electromagnetic stirring is used to mix the alloy evenly, and finally cast into round ingots. The melting process and casting process are carried out under the protection of vacuum or inert atmosphere.

[0040] (2) Ti will be obtained 4 wxya 2.5 Ta 2.5 The medium entropy alloy ingot was rolled at room temperature, the total rolling reduction was 81%, and the rolling pass was 15 times.

[0041] (3) The Ti after cold rolling 4 wxya 2.5 Ta 2.5...

Embodiment 2

[0044] Low activation refractory Ti 4 wxya 2.5 Ta 2.5 The preparation steps of medium entropy alloy are as follows:

[0045] (1) According to the required alloy atomic ratio, select the corresponding quality of pure Ti, pure V, pure Hf and pure Ta to configure as raw materials, the specific content is 40at.%Ti, 10at.%V, 25at.%Hf and 25at. %Ta. First put Ti and Ta, V and Hf together to prepare the master alloy by arc melting, and then put the master alloy together and use arc melting to form an ingot. During the smelting process, electromagnetic stirring is used to mix the alloy evenly, and finally cast into round ingots. The melting process and casting process are carried out under the protection of vacuum or inert atmosphere.

[0046] (2) Ti will be obtained 4 wxya 2.5 Ta 2.5 The medium entropy alloy ingot was rolled at room temperature, the total rolling reduction was 81%, and the rolling pass was 15 times.

[0047] (3) The Ti after cold rolling 4 wxya 2.5 Ta 2.5...

Embodiment 3

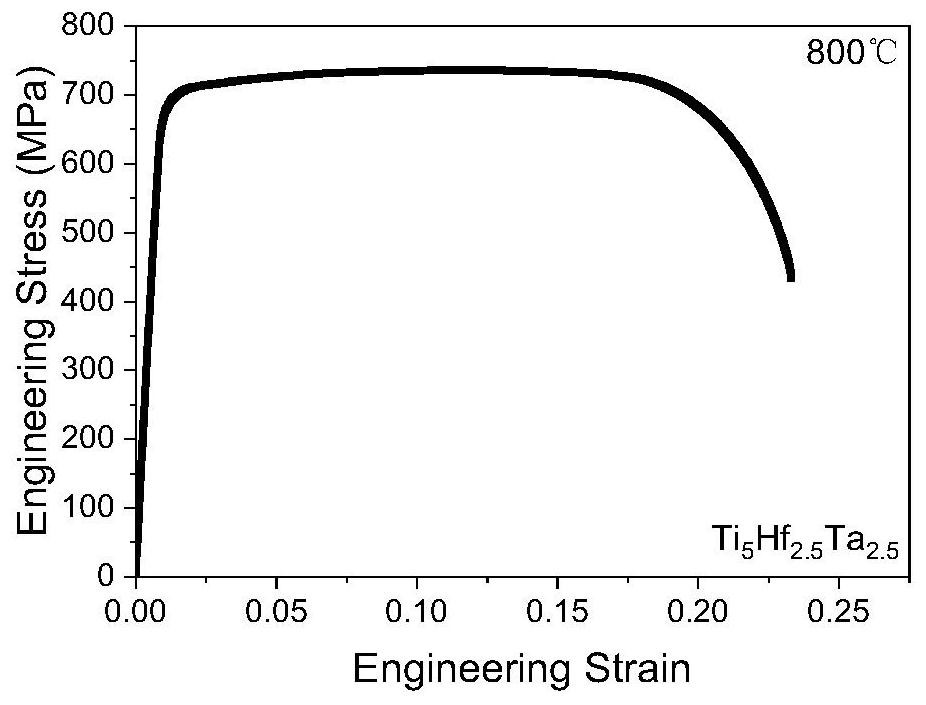

[0050] Low activation refractory Ti 3.5 V 1.5 f 2.5 Ta 2.5 The preparation steps of medium entropy alloy are as follows:

[0051] (1) According to the required alloy atomic ratio, select the corresponding quality of pure Ti, pure V, pure Hf and pure Ta to configure as raw materials, the specific content is 35at.%Ti, 15at.%V, 25at.%Hf and 25at. %Ta. First put Ti and Ta, V and Hf together to prepare the master alloy by arc melting, and then put the master alloy together and use arc melting to form an ingot. During the smelting process, electromagnetic stirring is used to mix the alloy evenly, and finally cast into round ingots. The melting process and casting process are carried out under the protection of vacuum or inert atmosphere.

[0052] (2) Ti will be obtained 3.5 V 1.5 f 2.5 Ta 2.5 The medium entropy alloy ingot was rolled at room temperature, the total rolling reduction was 79%, and the rolling pass was 15 times.

[0053] (3) The Ti after cold rolling 3.5 V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com