A kind of rapidly degradable graphene composite waterproof paper and preparation method thereof

A graphene composite and waterproof paper technology, which is applied in papermaking, paper, packaging paper, etc., can solve the problems of refractory degradation, environmental pollution, non-waterproof, etc., and achieve the effect of good bonding force, broad application prospects, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

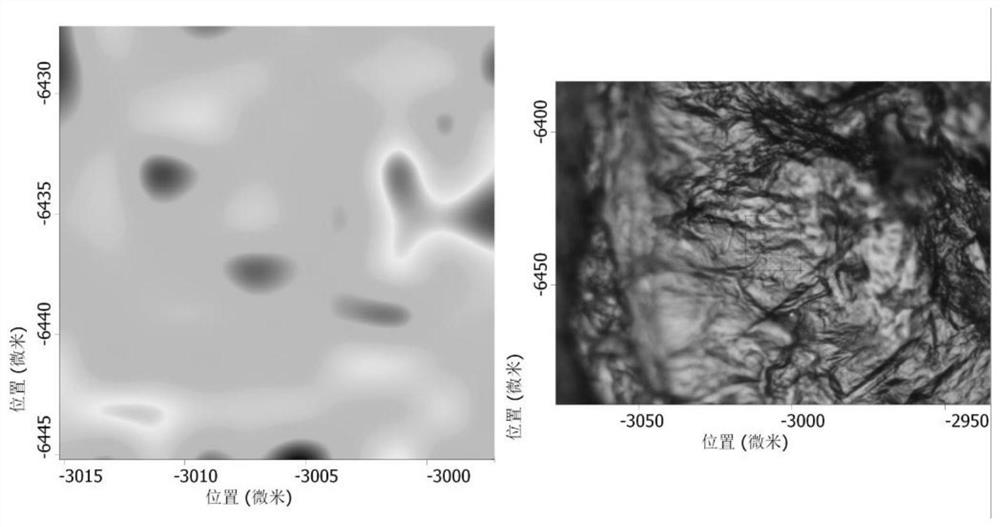

[0037] (1) At room temperature, weigh 500 mg of graphite oxide prepared by the modified Hummers method, place it in a 500 mL beaker, and then add 200 mL of deionized water to prepare a 2.5 mg / mL dispersion. Then put the beaker into a water-bath ultrasonic pool for 2 hours, then transfer it to a cell pulverizer for 1 hour to obtain 200 mL of a uniformly dispersed graphene oxide dispersion, which is transferred to a solution tray for use;

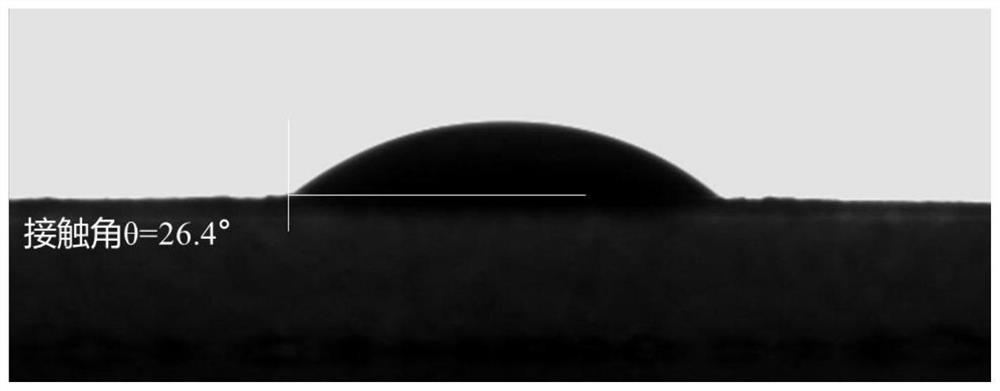

[0038] (2) The fiber paper to be used (Kraft paper for Galley packaging, breaking strength 185.0MPa, durability 26.3min (taking 5% moisture content at the bottom as failure point)) is treated with 20kV electric field polarization, so that the paper surface is positively charged, Then spread it on the surface of the dispersion liquid in step (1) for 10 minutes, so that one side of the paper base is completely soaked, and dry it.

[0039] (3) heat-treat the paper obtained in step (2) at 200° C. for 20 minutes to obtain a rapidly degradable grap...

Embodiment 2

[0044] According to embodiment 1, heat treatment temperature is changed into 300 ℃, heat treatment time is changed into 10min, all the other are identical with embodiment 1, obtain the graphene composite waterproof paper of fast degradation, its breaking strength 197.5MPa, durability is 118.6h (with 5% moisture content at the bottom is the point of failure).

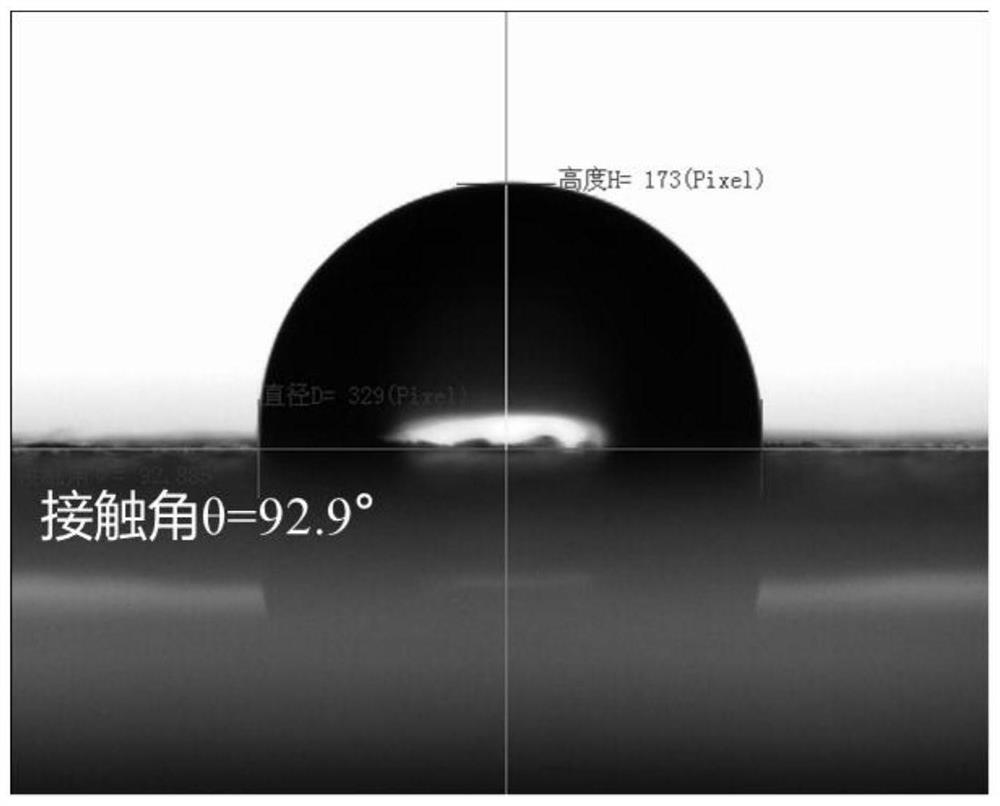

[0045] Figure 4 Compared figure 1 It can be seen that the hydrophobicity of the graphene composite waterproof paper is significantly improved after heat treatment, and its contact angle reaches 103.9°.

Embodiment 3

[0047] According to embodiment 1, heat treatment temperature is 300 DEG C, and heat treatment time is 20min, and all the other are identical with embodiment 1, obtain the graphene composite waterproof paper of rapid degradation, its breaking strength 189.7MPa, and durability is 138.7h (by moisture content at the bottom 5% is the point of failure).

[0048] Figure 5 Compared figure 1 It can be seen that the hydrophobicity of the graphene composite waterproof paper is significantly improved after heat treatment, and its contact angle reaches 142.7°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com