Extraction method of Cinnamomum camphora anthocyanin

An extraction method and technology of camphor fruit are applied in the field of high-efficiency extraction of plant anthocyanins, and can solve problems such as the influence of low-efficiency energy consumption on biologically active substances and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

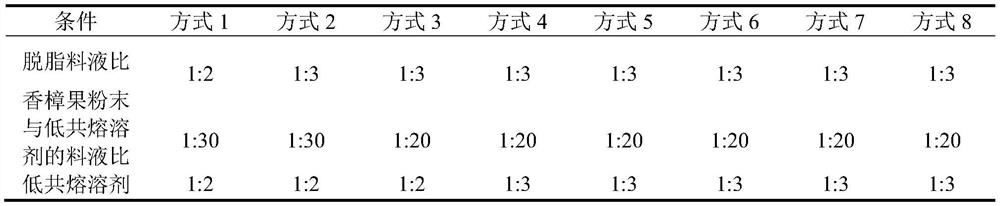

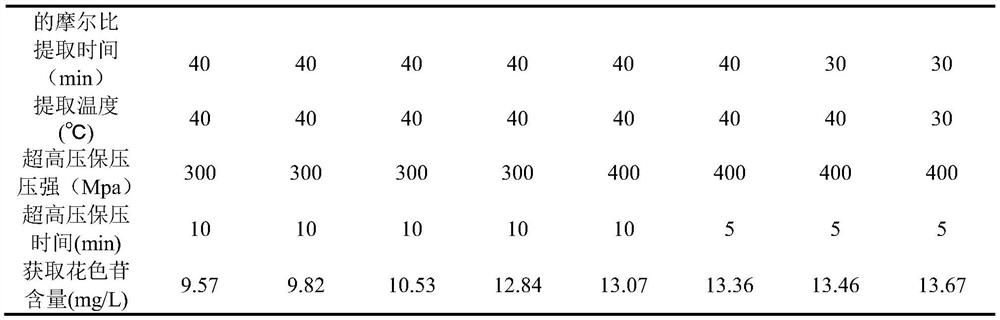

[0031] The collected camphor fruit raw materials were cleaned, cored, frozen at -80°C for 24 hours, then dried in a freeze dryer for 25 hours, mechanically crushed, and passed through a 60-mesh sieve to obtain camphor fruit powder; ethyl acetate was used at a ratio of 1:2 to liquid Extract and degrease the camphor fruit powder to obtain defatted camphor fruit powder; after drying in the shade, accurately weigh 1.00 g of the defatted camphor fruit powder and mix it with 30 mL of choline chloride-acetic acid type deep eutectic solvent with a molar ratio of 1:2 , according to the proportion of 20%, after adding water to dilute, the magnetic force is fully oscillated, and the extraction temperature is 40 ℃, and the extraction is 40 minutes. Then the resulting solution was raised from atmospheric pressure to 300Mpa in a closed container over 3 minutes, and then kept under the ultra-high pressure condition for 10 minutes, and then released to atmospheric pressure over 2 seconds. Aft...

Embodiment approach 2

[0033] This embodiment is roughly the same as Embodiment 1, and the only difference is that ethyl acetate is used to extract and degrease camphor fruit powder at a solid-to-liquid ratio of 1:3. Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

Embodiment approach 3

[0035] This embodiment is roughly the same as Embodiment 2, except that after drying in the shade, 1.00 g of defatted camphor fruit powder is accurately weighed and mixed with 20 mL of choline chloride-acetic acid type deep eutectic solvent with a molar ratio of 1:2. Apart from this, this embodiment is completely the same as Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com