Electronic-grade hydrofluoric acid preparation device

A technology for electronic grade hydrofluoric acid and preparation device, applied in the directions of hydrogen fluoride, fluorine/hydrogen fluoride, control/regulation process, etc., can solve the problems of small reaction contact area, reduce production efficiency, affect production efficiency, etc., achieve full reaction, improve The effect of production efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

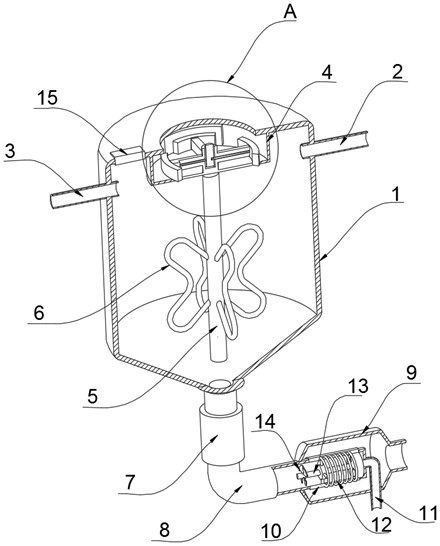

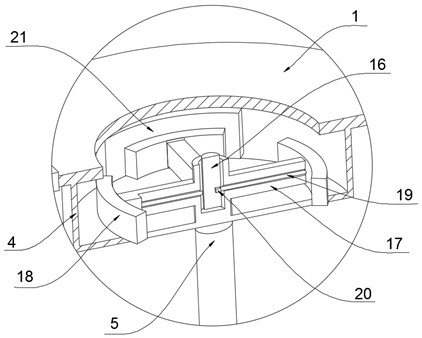

[0024] refer to Figure 1-6 , an electronic grade hydrofluoric acid preparation device, including a reaction tank 1, a fluorite feed port 2 and a sulfuric acid feed port 3 are respectively arranged above the reaction tank 1, and the fluorite feed port 2 and the sulfuric acid feed port 3 are connected with the reaction tank 1. The tank 1 is connected, the top of the reaction tank 1 is welded and fixed with a fixed box 4, the fixed box 4 is rotatably connected with a stirring shaft 5, the bottom of the stirring shaft 5 is symmetrically welded and fixed with a stirring ring 6, and the bottom of the reaction tank 1 is provided with a discharge valve 7.

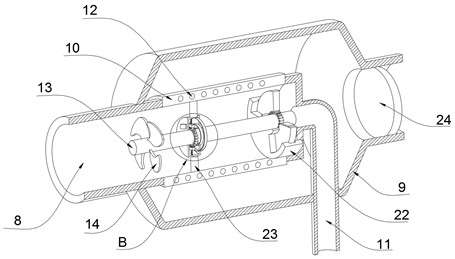

[0025] An electronic grade hydrofluoric acid preparation device, which also includes a water inlet pipe 8, which is connected to a discharge valve 7, and an outlet pipe 9 is connected to the outside of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com