Preparation method of high-functionality graphene diatomite composite material

A technology of graphene diatomite and composite materials, which is applied in the field of preparation and application of high-functional graphene diatomite composite materials, and can solve problems such as difficulty in extraction and dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

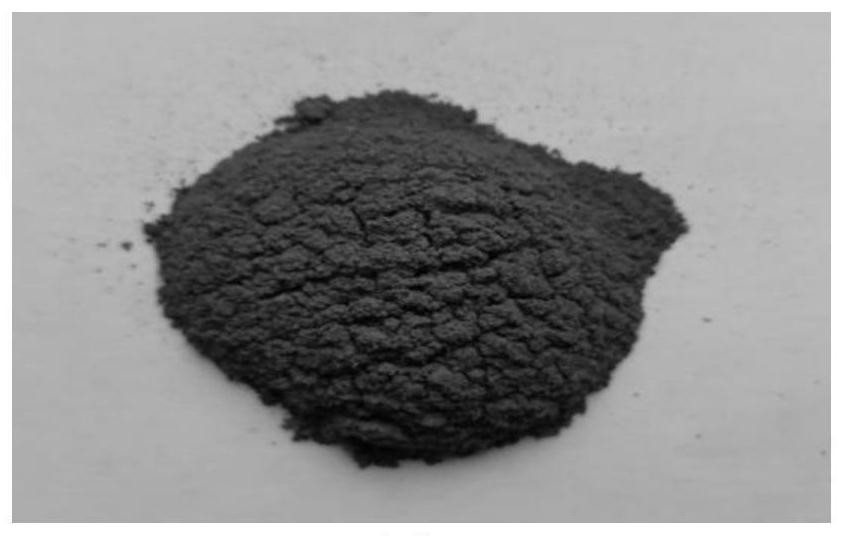

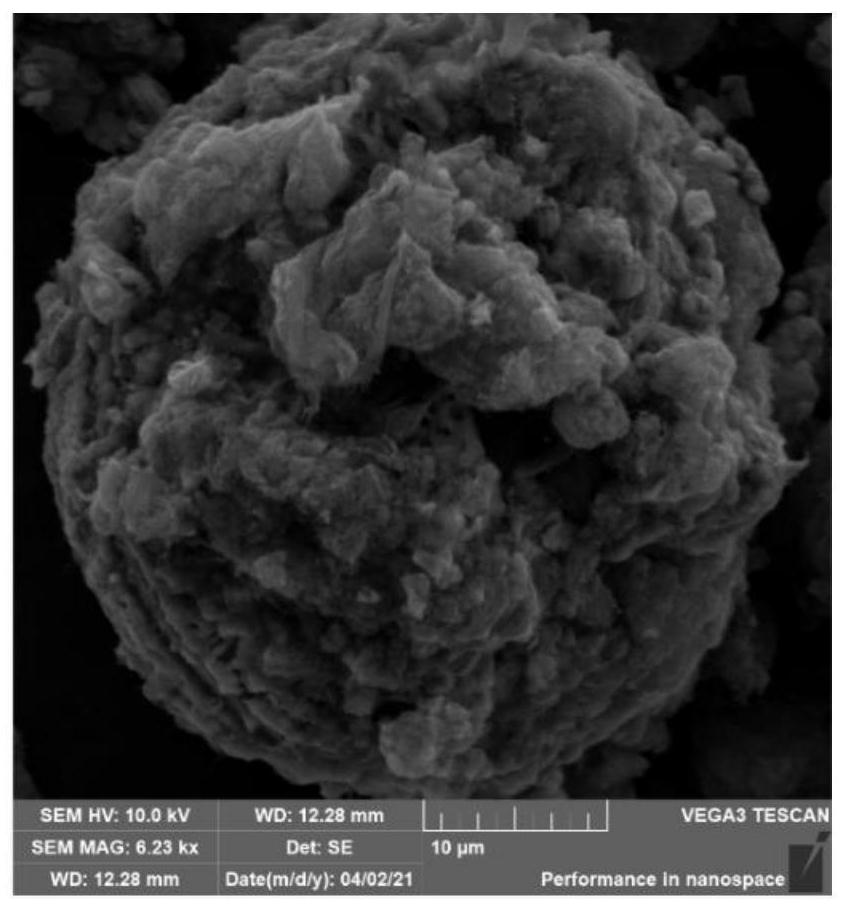

[0025] 1) According to the hummer method graphene preparation process, after compound oxidation of 1g of multilayer graphene and 50g of diatomite and tertiary diatomite, the product was washed to neutrality, and dried in a blast drying oven at 60°C to obtain graphite Diatomaceous earth composite material, optical photo as figure 1 As shown, the electron microscope photos are as figure 2 shown, and then ground into powder for later use.

[0026] 2) get step 1) graphene diatomite composite material 20g prepared, ultrasonic dispersion 30 minutes under the condition of 100 watts, obtain graphene diatomite composite material dispersion liquid, as image 3 shown.

[0027] 3) Disperse 2g of latex powder, 0.8g of dispersant, and 0.5g of cellulose in deionized water, and disperse at a high speed under the condition of 5000 rpm, stir for 5 minutes and compound with graphene diatomite in step 2) The material dispersion was blended and stirred for 5 minutes before use.

[0028] 4) Ad...

Embodiment 2

[0030] 1) According to the hummer method graphene preparation process, after the multi-layer graphene 1g and the second and third grade diatomite 40g are prepared by composite oxidation, the obtained graphene diatomite composite material is washed to neutrality, and placed in a blast drying oven Dry at 60°C, and then grind into powder for later use.

[0031] 2) Take 23 g of the graphene-diatomite composite material prepared in step 1), and ultrasonically disperse it under the condition of 100 watts for 30 minutes to obtain the graphene-diatomite composite material dispersion.

[0032] 3) Disperse 2.5g of latex powder, 1.0g of dispersant, and 0.8g of cellulose in deionized water, and disperse at a high speed under the condition of 5000 rpm, and blend with the graphene dispersion in step 2 after stirring for 5 minutes Stir for 5 minutes and set aside.

[0033] 4) Add 45g of heavy calcium powder, 18g of gray calcium powder, and 2.5g of nano-zinc oxide into step 3, disperse and s...

Embodiment 3

[0035] 1) According to the hummer method graphene preparation process, after the multi-layer graphene 1g and the second and third grade diatomite 30g are prepared by composite oxidation, the obtained graphene diatomite composite material is washed to neutrality, and placed in a blast drying oven Dry at 60°C, and then grind into powder for later use.

[0036] 2) Take 26 g of the graphene-diatomite composite material prepared in step 1), and ultrasonically disperse it under the condition of 100 watts for 30 minutes to obtain the graphene-diatomite composite material dispersion.

[0037] 3) Disperse latex powder 3g, dispersant 1.1g, and cellulose 1.0g in deionized water, and disperse at a high speed under the condition of 5000 rpm, stir for 5 minutes, and blend and stir with the graphene dispersion in step 2 Set aside for 5 minutes.

[0038] 4) Add 50g of heavy calcium powder, 18g of gray calcium powder, and 3g of nano-zinc oxide into step 3, disperse and stir at high speed for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com