Chlor-alkali and sodium chlorate combined denitration process

A technology of sodium chlorate and chlor-alkali, which is applied in the field of chlor-alkali and sodium chlorate joint denitration process, can solve the problems of difficult treatment, chromium cannot be recovered, and affect the electrolysis efficiency of the sodium chlorate electrolysis system, and achieve the effect of slowing down the effect of oxidation and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

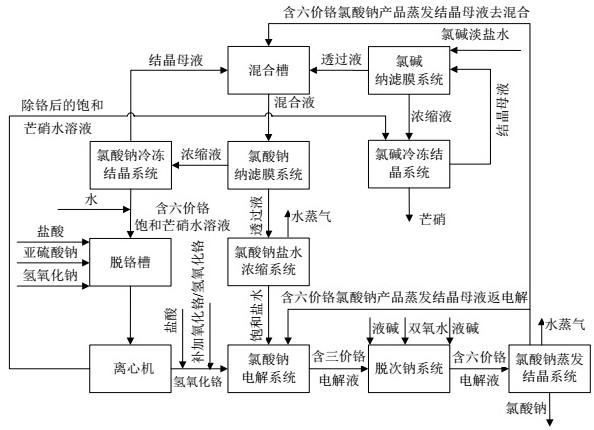

Method used

Image

Examples

Embodiment

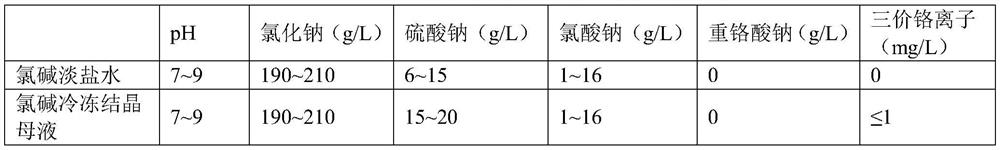

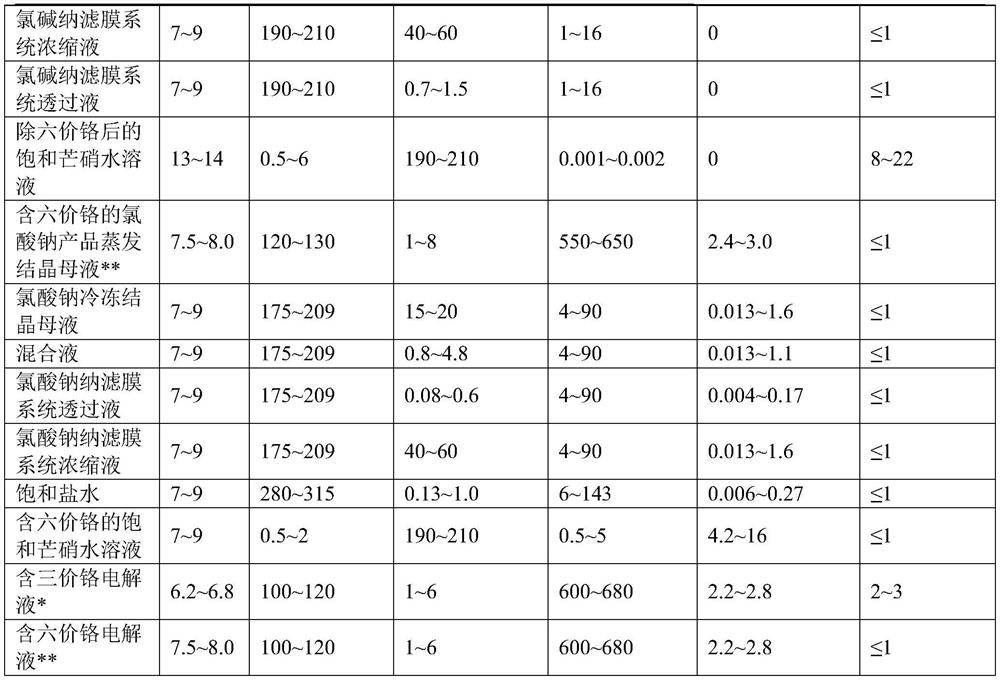

[0043] Taking 50,000 tons / year of sodium chlorate and 100,000 tons / year of chlor-alkali equipment as examples, the chlor-alkali light brine (pH value 9, containing 200g / L sodium chloride, 6g / L sodium sulfate, and chloric acid) from the chlor-alkali system Sodium 1g / L) and chlor-alkali freeze crystallization system crystallization mother liquor (pH value 9, containing sodium chloride 200g / L, sodium sulfate 17.5g / L, sodium chlorate 1g / L, trivalent chromium ion not higher than 1mg / L) Concentrate through the chlor-alkali nanofiltration membrane system after mixing, and its concentrated solution (pH value 9, containing 200g / L sodium chloride, 50g / L sodium sulfate, 1g / L sodium chlorate, 0.2mg / L trivalent chromium ion) and Saturated Glauber's salt aqueous solution (pH value 14, containing sodium chloride 1g / L, sodium sulfate 200g / L, sodium chlorate 2mg / L, trivalent chromium ion 12mg / L) from the sodium chlorate system was mixed Enter the crystallization of chlor-alkali freezing crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com