A permeable cross-linked reinforced anti-corrosion material for concrete cooling towers and its application

A technology of anti-corrosion materials and reinforcement materials, applied in the field of building materials, can solve the problems of destroying concrete, concrete performance and structural stability decline, and achieve the effects of improving compressive strength, solving performance and structural stability decline, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

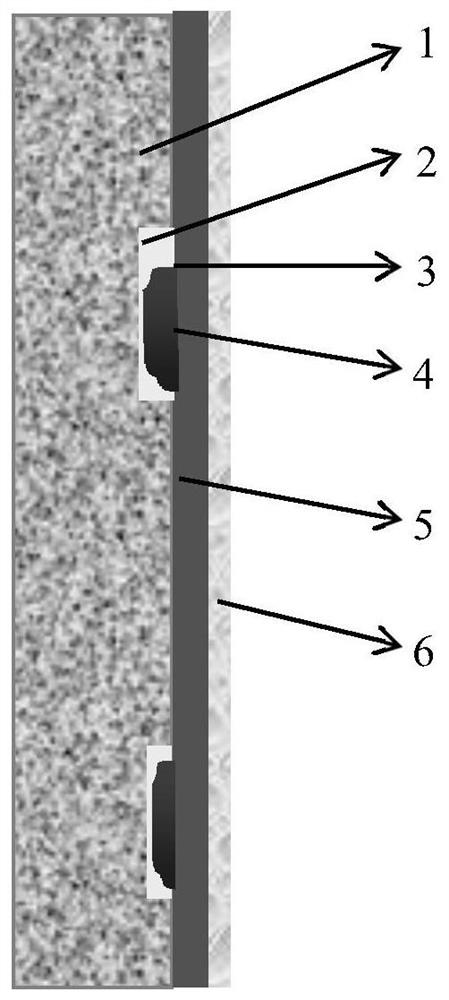

Image

Examples

preparation example Construction

[0062] Preferably, the preparation method of the micron-sized diamine@MOF particles comprises: adding aluminum nitrate and 4,4'-biphenyldicarboxylic acid to the Disperse evenly in water, heat up to 160-200°C, then adjust the pH of the resulting solution to 2-4, and keep it warm for 5-10 hours; after the reaction, filter, wash, dry and pulverize to obtain micron-sized aluminum MOF particles ;Immerse aluminum MOF particles in a diamine solution (isophoronediamine, m-phenylenediamine or m-xylylenediamine), let it stand for 2-4h for adsorption, and centrifuge to obtain micron-sized diamine@MOF particles.

[0063] A method for strengthening and anti-corrosion treatment of cooling towers, comprising the following steps:

[0064] S1: Clean up the cooling tower base.

[0065] S2: Spray anti-salt reinforcement material to the cooling tower substrate for anti-salt reinforcement treatment (amount of 90-110g / m 2 ) to prevent salt substances from further invading the cooling tower matri...

Embodiment 1

[0071] A permeable cross-linked reinforced anti-corrosion material for concrete cooling towers, including salt-resistant reinforcing material, base surface repair mortar, base surface reinforcement material, bottom layer anti-corrosion material and surface layer anti-corrosion material, which are sequentially coated or injected on the concrete base surface The anti-corrosion material of the surface layer is divided into the anti-corrosion material of the inner wall surface layer and the anti-corrosion material of the outer wall surface layer; wherein:

[0072] The salt-resistant reinforcing material includes the following components in mass percentage: 3.5% of potassium silicate with a maximum particle size of less than 20nm, 15% of acrylate polymer, 3.5% of polysiloxane, 0.75% of ethoxylated tridecyl alcohol, water balance.

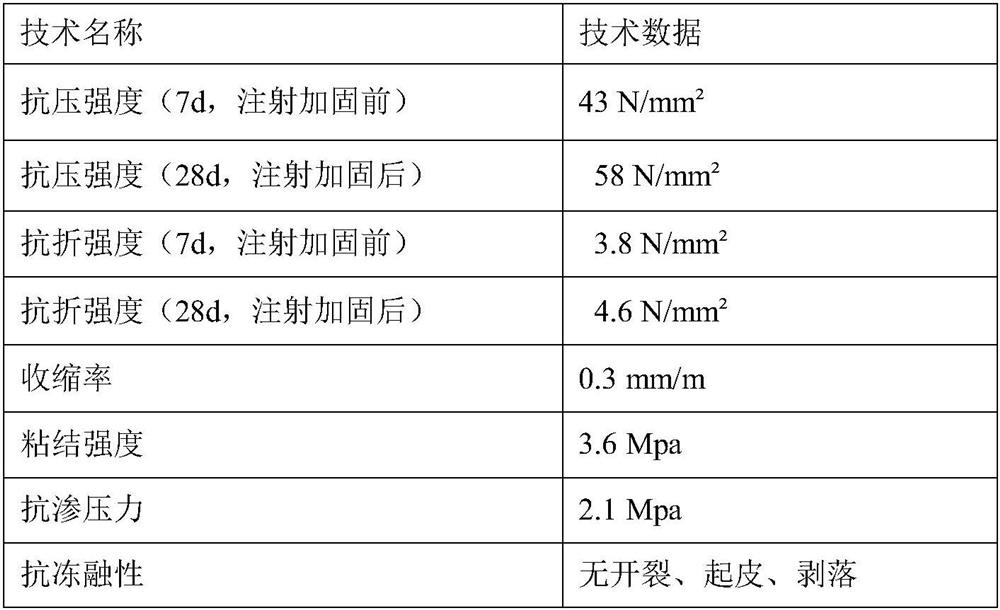

[0073] technical name Technical data main ingredient polymer, silicate particle diameter 20nm density 1.03g / cm 3

...

Embodiment 2

[0086] A permeable cross-linked reinforced anti-corrosion material for concrete cooling towers, including salt-resistant reinforcing material, base surface repair mortar, base surface reinforcement material, bottom layer anti-corrosion material and surface layer anti-corrosion material, which are sequentially coated or injected on the concrete base surface The anti-corrosion material of the surface layer is divided into the anti-corrosion material of the inner wall surface layer and the anti-corrosion material of the outer wall surface layer; wherein:

[0087] The salt-resistant reinforcing material includes the following components in mass percentage: 2% of potassium silicate with a maximum particle size of less than 20nm, 20% of acrylate polymer, 2% of polysiloxane, 1% of ethoxylated tridecyl alcohol, Water 75%.

[0088] The base surface repair mortar includes the following components in mass percentage: 55% of natural quartz sand, and the specific surface area is greater th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com