Polyimide porous membrane and preparation method thereof

A technology of polyimide and porous membrane, which is applied in the field of polymer dielectric material preparation, can solve the problems of poor thermal stability, poor dimensional stability, and uneven pore distribution, and achieve good thermal stability and dimensional stability Good, dimensional stability and high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

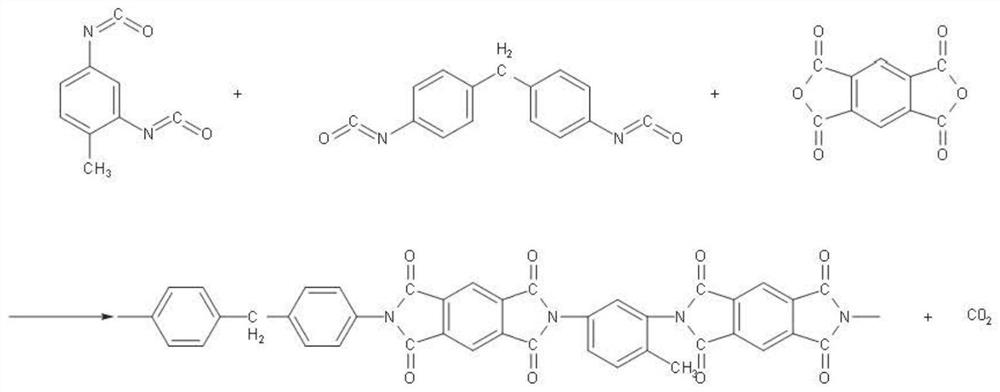

[0071] (1) Under the condition of nitrogen protection and 25°C, 0.08mol (13.93g) of 4-methyl-m-phenylene diisocyanate and 0.02mol (5g) of 4,4'-methylenebis(iso Phenyl cyanate) was dissolved in a three-necked flask with 230.86g of NMP, and 0.1mol (21.81g) of 1,2,4,5-benzenetetracarboxylic dianhydride was added and stirred for 5h to obtain a solid content of 15%. The intermediate product polyamic acid solution.

[0072] (2) The obtained polyamic acid solution is added to nano-SiO with an average particle diameter of 30nm 2 (Add 0.05g SiO per 100g polyamic acid 2 ), mixed evenly and defoamed, after defoaming, coated on a clean glass plate with an automatic film coating machine, the thickness of the coating film was 300 μm, placed the glass plate in an oxygen-free oven, and used stepwise heating (heating to 100°C for heat preservation 30min, then raise the temperature to 110°C for 30min, then raise the temperature to 120°C for 60min, then raise the temperature to 140°C for 60min...

Embodiment 2

[0074] (1) Under the condition of nitrogen protection and 25°C, 0.08mol (13.93g) of 4-methyl-m-phenylene diisocyanate and 0.02mol (5g) of 4,4'-methylenebis(iso Phenyl cyanate) was dissolved in a three-necked flask with 230.86g of NMP, and 0.1mol (21.81g) of 1,2,4,5-benzenetetracarboxylic dianhydride was added and stirred for 5h to obtain a solid content of 15%. The intermediate product polyamic acid solution.

[0075] (2) The obtained polyamic acid solution is added to nano-SiO with an average particle diameter of 30nm 2 (Add 0.05g SiO per 100g polyamic acid 2 ), mixed evenly and defoamed, after defoaming, coated on a clean glass plate with an automatic film coating machine, the thickness of the coating film was 300 μm, placed the glass plate in an oxygen-free oven, and used stepwise heating (heating to 100°C for heat preservation 30min, then raise the temperature to 110°C for 30min, then raise the temperature to 120°C for 60min, then raise the temperature to 140°C for 60min...

Embodiment 3

[0077] (1) Under the condition of nitrogen protection and 25°C, 0.08mol (13.93g) of 4-methyl-m-phenylene diisocyanate and 0.02mol (5g) of 4,4'-methylenebis(iso Phenyl cyanate) was dissolved in a three-necked flask with 230.86g of NMP, and 0.1mol (21.81g) of 1,2,4,5-benzenetetracarboxylic dianhydride was added and stirred for 5h to obtain a solid content of 15%. The intermediate product polyamic acid solution.

[0078] (2) The obtained polyamic acid solution is added into nano-SiO with an average particle diameter of 5nm 2 (Add 0.05g SiO per 100g polyamic acid 2 ), mixed evenly and defoamed, after defoaming, coated on a clean glass plate with an automatic film coating machine, the thickness of the coating film was 300 μm, placed the glass plate in an oxygen-free oven, and used stepwise heating (heating to 100°C for heat preservation 30min, then raise the temperature to 110°C for 30min, then raise the temperature to 120°C for 60min, then raise the temperature to 140°C for 60mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com