Cold-rolled high-strength steel with good coating quality and preparation method thereof

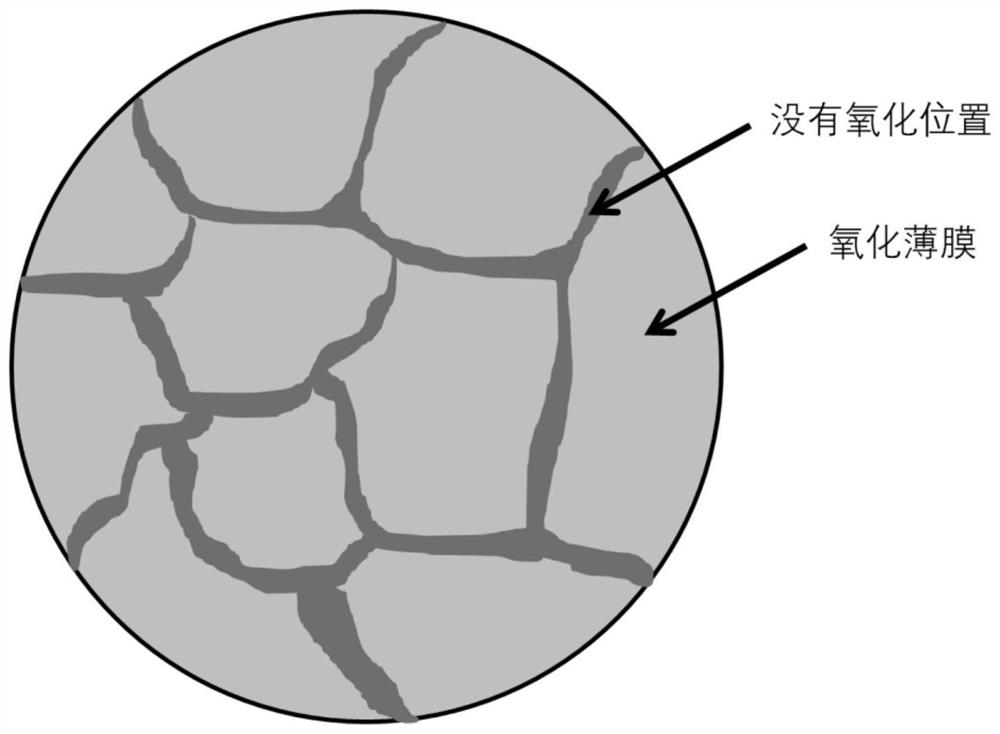

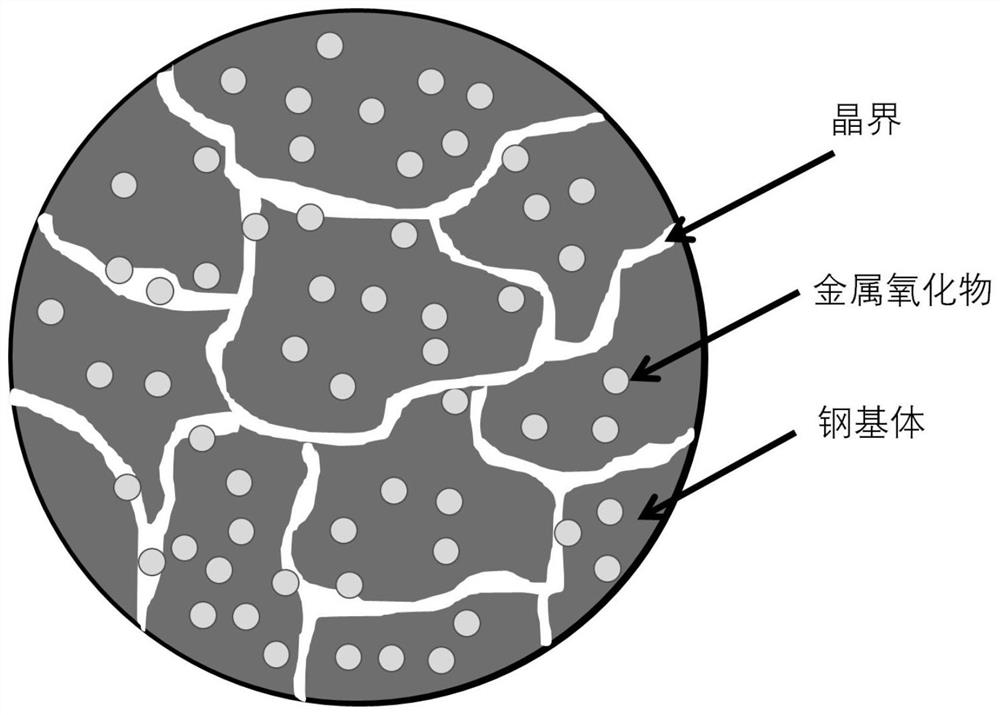

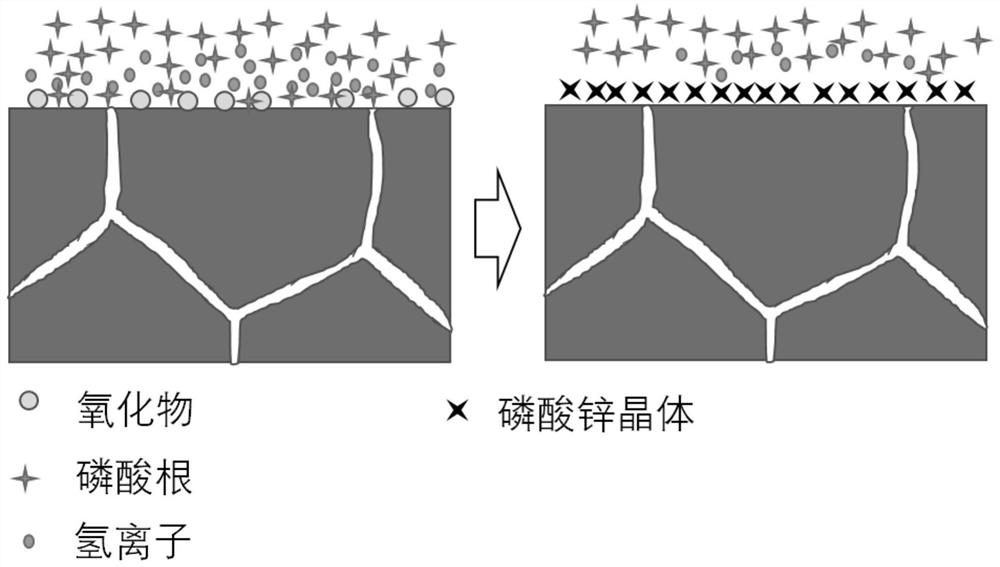

A high-strength steel, high-quality technology, used in manufacturing tools, heat treatment equipment, metal material coating processes, etc., can solve problems such as inability to form phosphating film, difficulty in surface phosphating, and poor quality of electrophoretic film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] According to another exemplary embodiment of the present invention, the preparation method of cold rolling high strength steel having good quality is provided, and the preparation method comprises:

[0049] The chemical composition of cold-rolled high-strength steel using the coating quality is cast, and a continuous casting slab is obtained.

[0050] The continuous casting slab is heated, and then coarse rolled, fine rolled, and then cooled, and the hot rolled finished product was obtained.

[0051] The hot rolled finished product is acid washing and cold rolling to obtain a cold and hard belt steel;

[0052] The cold hard belt steel is annealed, and then the surface coating treatment is performed to obtain a cold rolled high-strength steel having good quality quality.

[0053] As an alternative embodiment, the heating temperature is 1235 ° C to 1285 ° C, and the temperature is 180 min; the finishing temperature of the finishing is ≥900 ° C, the winding temperature of 520 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com