Isoprene polymer latex composition

A polymer glue, isoprene technology, used in other household appliances, coatings, household components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

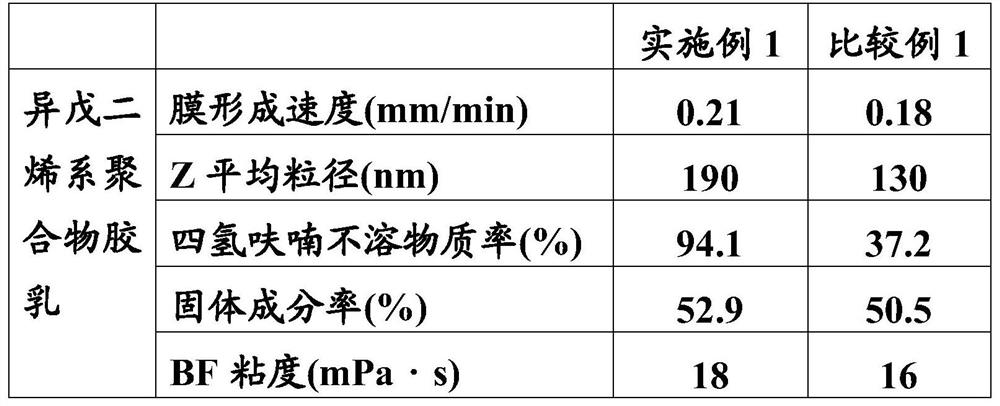

Examples

Embodiment 1

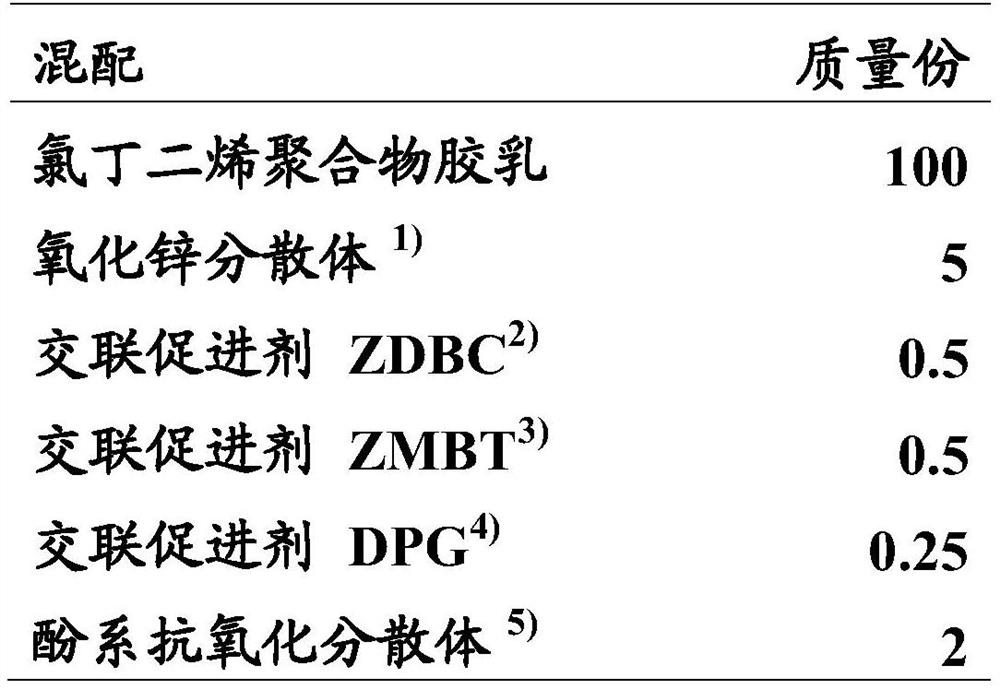

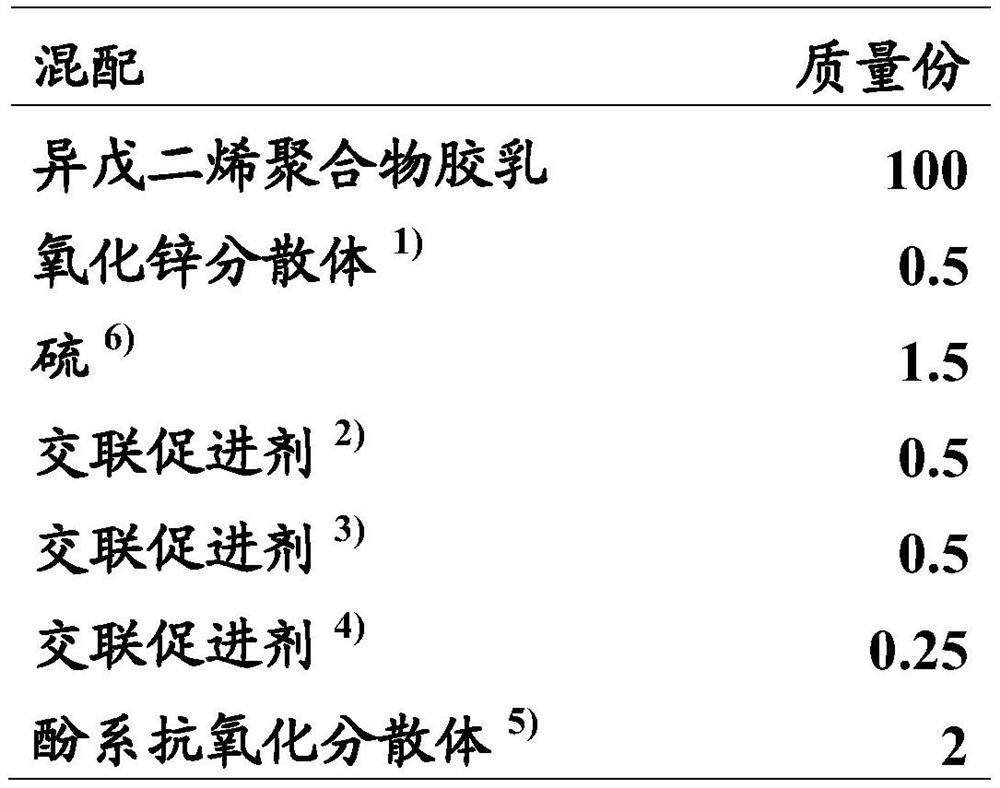

[0095] Modulation of chloroprene polymer latex and composition thereof:

[0096] Using a reactor with an internal volume of 5 liters, 1.83 kg of 2-chloro-1,3-butadiene (chloroprene) (manufactured by Tokyo Chemical Industry Co., Ltd.), 2,3-dichloro-1,3-butane Diene (manufactured by Tokyo Chemical Industry Co., Ltd.) 0.17 kg, pure water 1.12 kg, abietic acid (manufactured by Arakawa Chemical Industry Co., Ltd., R-300) 34 g, 20% by mass potassium hydroxide aqueous solution (manufactured by Fuji Film Wako Junpharmaceutical Co., Ltd. Premium product) 106.6 g, sodium salt of β-naphthalenesulfonic acid formaldehyde condensate (manufactured by Kao Corporation) 24 g, sodium dodecylbenzenesulfonate (manufactured by Kao Corporation, Neoperex (registered trademark) G-15) 6.0 g, make it emulsified, after making rosin acid into rosin soap, use potassium persulfate (Fuji Filum Wako Junpharma Co., Ltd. first-class product) as initiator, under nitrogen atmosphere, carry out 5 at initial temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com