Anti-pollution reverse osmosis membrane and preparation method and application thereof

A reverse osmosis membrane and anti-pollution technology, applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problem of low water flux of anti-pollution reverse osmosis membrane, and achieve production cost Inexpensive, simple and easy to control preparation method, good anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention proposes a preparation method of an anti-pollution reverse osmosis membrane for the first time: comprising the following steps:

[0045] S1: Add a surfactant and a water-soluble crosslinking agent to the aqueous solution of the polymer, and mix well to obtain an aqueous phase solution; the surfactant is an anionic surfactant and / or cationic surfactant; the polymer is a neutral water-soluble polymer substance and / or charged water-soluble polymer; the mass fraction of the polymer in the aqueous phase solution is 0.1-5%; the mass fraction of the surfactant in the aqueous phase solution is 0.1-5%; the crosslinking agent in the aqueous phase solution The mass fraction is 0.1-0.5%.

[0046]S2: apply the aqueous phase solution in S1 on the composite membrane, let it stand for 30s-1min, pour off the excess aqueous phase solution on the composite membrane, and obtain a mixed composite membrane;

[0047] S3: Immediately react the composite membrane mixed in...

Embodiment 1

[0055] A preparation method of anti-pollution reverse osmosis composite membrane:

[0056] S1: Prepare an aqueous solution of polyvinylpyrrolidone with a mass fraction of 0.5%, add sodium lauryl sulfate with a mass fraction of 0.5%, mix well, then add glutaraldehyde with a mass fraction of 0.3%, mix well, and obtain aqueous solution;

[0057] S2: apply the uniformly mixed aqueous phase solution on the composite membrane, and pour off the excess aqueous phase solution after standing for 45 seconds;

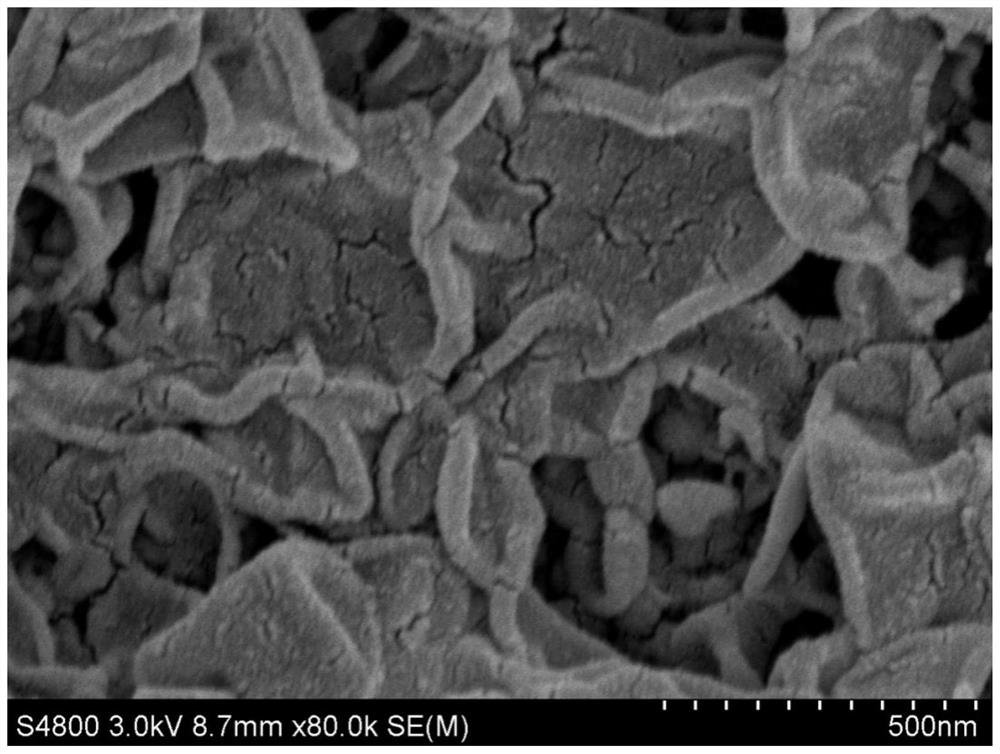

[0058] S3: Immediately put the membrane into a microwave blast drying oven for 40 seconds, set the temperature at 85° C., take out the composite membrane, and obtain an anti-pollution reverse osmosis composite membrane. The anti-pollution reverse osmosis composite membrane prepared in this implementation is scanned by electron microscope, and the electron microscope photo is figure 1 shown.

[0059] The anti-pollution reverse osmosis composite membrane of this embodiment is test...

Embodiment 2

[0062] A preparation method of anti-pollution reverse osmosis composite membrane:

[0063] The mass fraction of sodium lauryl sulfate in step S1 is 0.1%, and the other steps are the same as the preparation method in Example 1.

[0064] The anti-pollution reverse osmosis composite membrane of this embodiment is tested at a pressure of 0.75MPa, a concentrated water flow rate of 1.0GPM, an ambient temperature of 25°C, a concentrated water pH of 6.5 to 7.5, and a concentrated water feed of 500PPm sodium chloride. Under these conditions, the highest interception rate of the composite membrane to sodium chloride is 99.4%, and the highest water flux is 74LMH.

[0065] After the anti-pollution reverse osmosis composite membrane in this example is continuously operated for 100 hours through 500ppm bovine serum albumin aqueous solution + 500ppm sodium chloride as the feed liquid, the rejection rate of the membrane to sodium chloride is the highest at 99.3%, and the water flux is the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

| Water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com