Topological chemical reduction Eu < 3 + >/Eu < 2 + > co-doped UV-LED white light microcrystalline glass and preparation method thereof

A UV-LED, topological chemistry technology, applied in the field of inorganic non-metallic luminescent materials, to achieve the effect of simple process and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

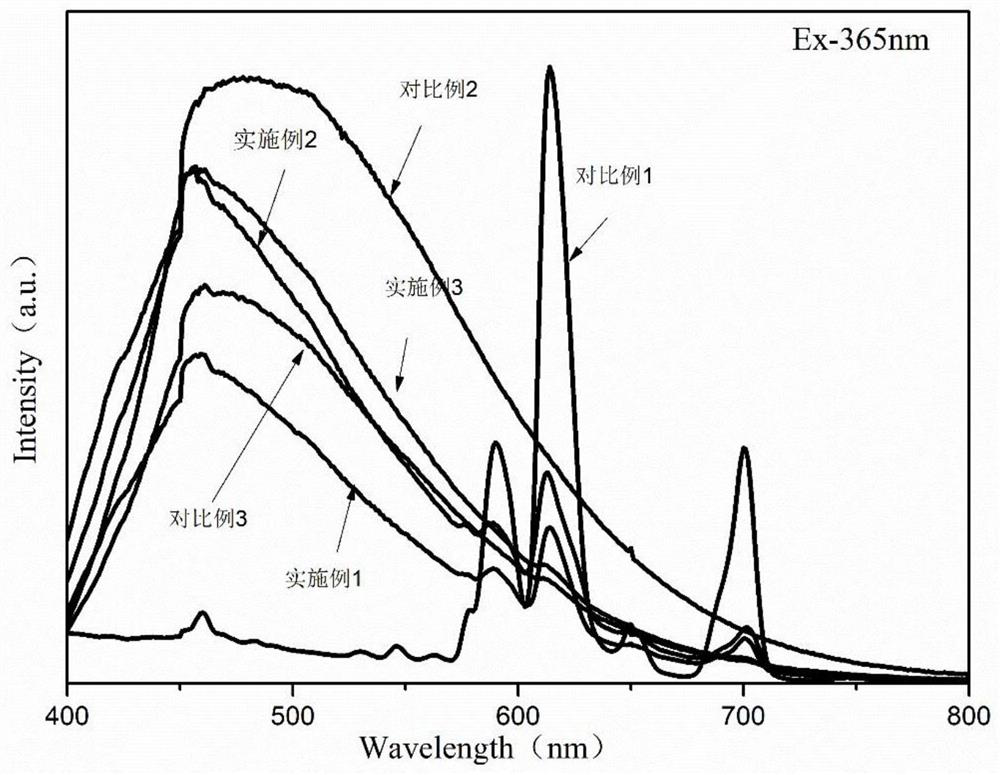

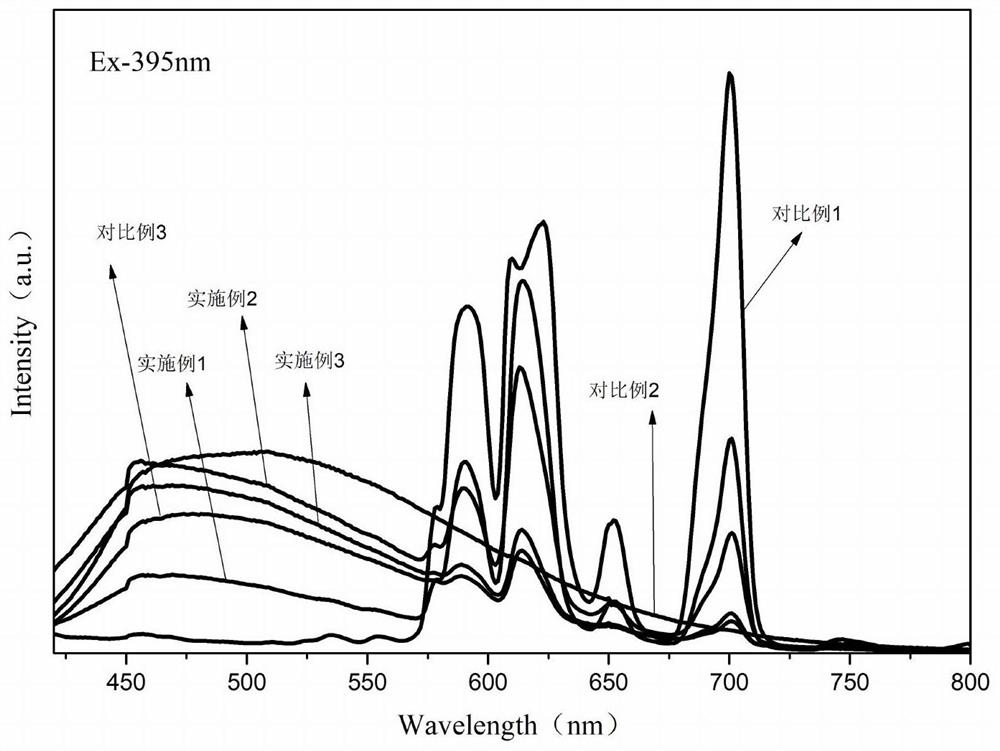

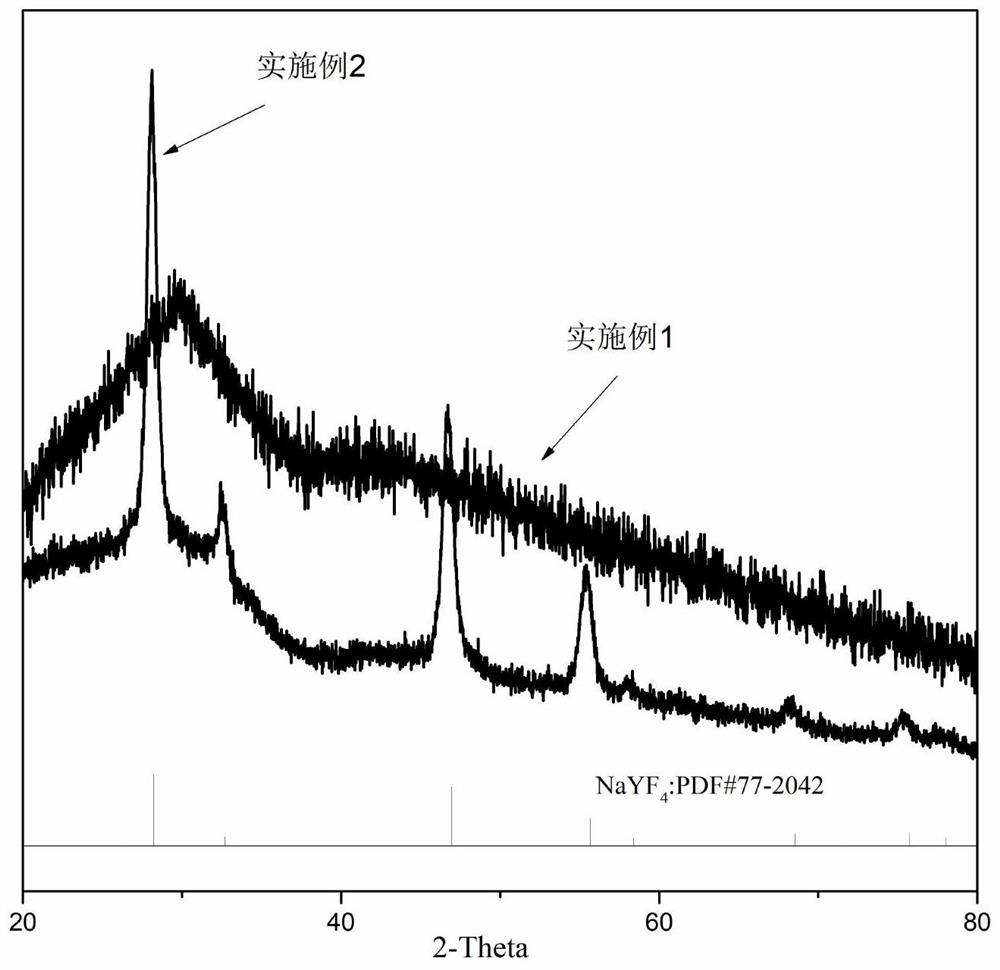

Embodiment 1

[0030] The white light LED glass sample of this embodiment comprises the following components in terms of molar percentages:

[0031] 40SiO 2 -25Al 2 o 3 -18Na 2 CO 3 -10YF 3 -7NaF-0.5Eu 2 o 3 -0.05Si 3 N 4

[0032] (1) Take each required composition raw material respectively by molar percentage;

[0033] (2) Grind and mix the raw materials in an agate mortar, put them into a corundum crucible, and calcine at 1400°C for 45 minutes to completely melt the powder mixture. It is not necessary to carry out under the protection of the atmosphere when melting at high temperature. Can be carried out in the air;

[0034] (3) Pour the material in the molten state onto the preheated copper plate in the muffle furnace, and perform stress relief annealing treatment at 350°C for 3 hours, and then cool to room temperature with the furnace;

[0035](4) Take out the sample from the muffle furnace, then grind the sample into a disc glass with a radius of 30 mm and a thickness of 3 m...

Embodiment 2

[0040] The white light LED glass sample of this embodiment comprises the following components in terms of molar percentages:

[0041] 40SiO 2 -25Al 2 o 3 -18Na 2 CO 3 -10YF 3 -7NaF-0.5Eu 2 o 3 -0.05Si 3 N 4

[0042] (1) Take each required composition raw material respectively by molar percentage;

[0043] (2) Grind and mix the raw materials in an agate mortar, put them into a corundum crucible, and calcine at 1400°C for 45 minutes to completely melt the powder mixture. It is not necessary to carry out under the protection of the atmosphere when melting at high temperature. Can be carried out in the air;

[0044] (3) Pour the material in the molten state onto the preheated copper plate in the muffle furnace, and perform stress relief annealing treatment at 350°C for 3 hours, and then cool to room temperature with the furnace;

[0045] (4) Put the cooled glass sample into a muffle furnace at 560°C for heat treatment for 4 hours;

[0046] (5) Take out the sample from...

Embodiment 3

[0051] The white light LED glass sample of the present embodiment, according to mole percentage, comprises following components:

[0052] 40SiO 2 -25Al 2 o 3 -18Na 2 CO 3 -10YF 3 -7NaF-0.5Eu 2 o 3 -0.1Si 3 N 4

[0053] (1) Take each required composition raw material respectively by molar percentage;

[0054] (2) Grind and mix the raw materials in an agate mortar, put them into a corundum crucible, and calcine at 1400°C for 45 minutes to completely melt the powder mixture. It is not necessary to carry out under the protection of the atmosphere when melting at high temperature. Can be carried out in the air;

[0055] (3) Pour the material in the molten state onto the preheated copper plate in the muffle furnace, and perform stress relief annealing treatment at 350°C for 3 hours, and then cool to room temperature with the furnace;

[0056] (4) Take out the sample from the muffle furnace, then grind the sample into a disc glass with a radius of 30 mm and a thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com