Preparation method of ethylene-vinyl acetate copolymer porous shape memory material

A vinyl acetate copolymer and vinyl acetate copolymerization technology, applied in the field of polymer materials, can solve the problems of complex process flow, increase production cost, uneven material pore diameter, etc., achieve simple and feasible process process, avoid collapse and damage, and mild process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

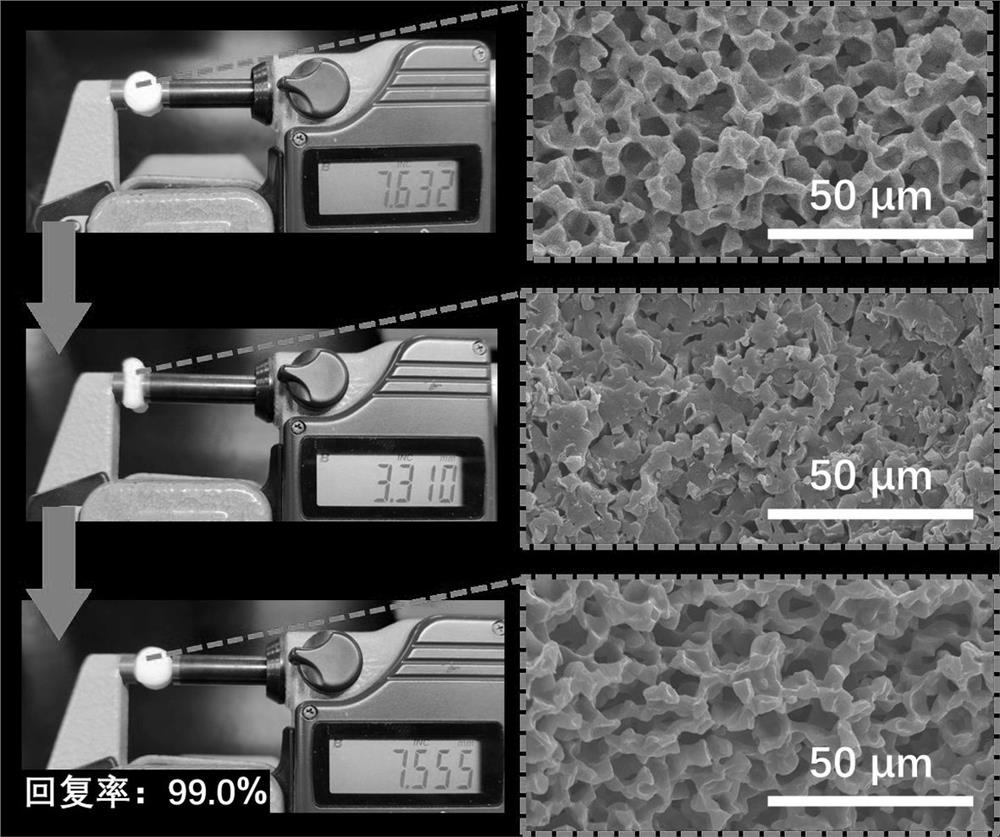

[0032] A simple and easy method for preparing EVA porous shape memory material, it comprises the following steps:

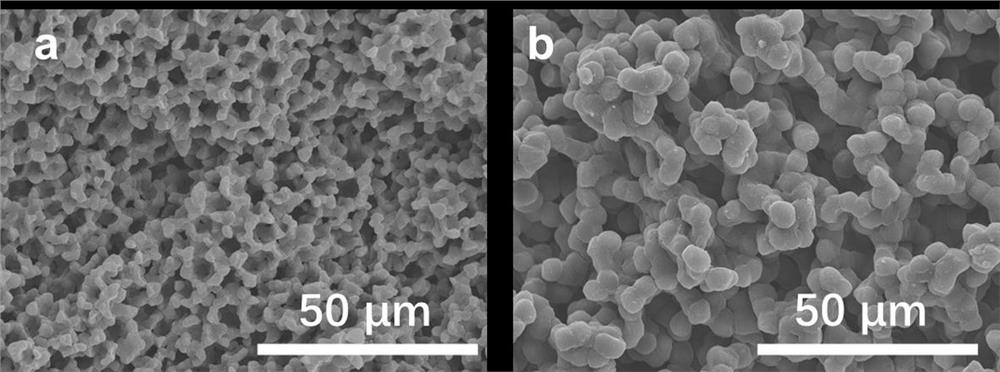

[0033] Step 1, dissolve ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate content of 18%-32% in a mixed solvent of toluene and n-propanol (3:1) at 70°C to obtain a concentration of 100-180mg / mL of EVA solution;

[0034] Step 2, transfer the above EVA solution to the mold, and conduct a low-temperature (0-50°C) water bath for 0.5-1 hour to induce phase separation to obtain a porous EVA material;

[0035] Step 3: Transfer the above porous EVA material to an acetone solution (concentration: 0.01-0.1g / mL) dissolved with benzoyl peroxide, soak for 3 hours, heat to 70°C and react for 2-6 hours to complete cross-linking , to obtain a cross-linked product;

[0036] In step 4, the above-mentioned cross-linked product is washed and dried under reduced pressure to prepare an EVA porous shape memory material.

[0037] The mass fraction of vinyl acetate in the e...

Embodiment 1

[0040] Step 1, dissolve the EVA (Elvax460, DuPont, USA) pellets with a vinyl acetate content of 18% in a mixed solvent of toluene and n-propanol (3:1) at 70°C to obtain an EVA solution with a concentration of 180mg / mL .

[0041] Step 2, the above solution was transferred to a cylindrical mold, and placed in a low-temperature water bath at 45° C. for 0.5 hour to induce phase separation to obtain a porous EVA material.

[0042] Step 3: Transfer the above EVA material to an acetone solution (concentration: 0.05g / mL) dissolved with benzoyl peroxide, soak for 3 hours, heat to 70°C and react for 5 hours to complete the cross-linking.

[0043] In step 4, the cross-linked porous EVA is taken out, washed with ethanol, and dried under reduced pressure at room temperature to obtain the EVA porous shape memory material.

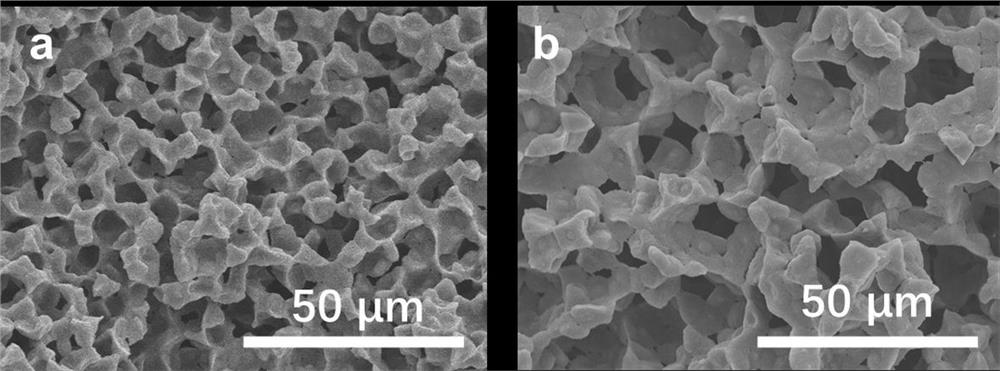

Embodiment 2

[0045] Step 1, dissolve EVA (Elvax460, DuPont, USA) pellets with 18% vinyl acetate content in a mixed solvent of toluene and n-propanol (3:1) at 70°C to obtain concentrations of 120 mg / mL and 100 mg / mL mL of EVA solution.

[0046] Step 2, the above solution was transferred to a cylindrical mold, and placed in a low-temperature water bath at 45° C. for 0.5 hour to induce phase separation to obtain a porous EVA material.

[0047] Step 3: Transfer the above-mentioned porous EVA material to an acetone solution (concentration: 0.05 g / mL) dissolved with benzoyl peroxide, soak for 3 hours, heat to 70°C and react for 5 hours to complete cross-linking.

[0048]In step 4, the cross-linked porous EVA is taken out, washed with ethanol, and dried under reduced pressure at normal temperature to prepare the EVA porous shape memory material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com