A kind of halovibrio using volatile fatty acid and its application

A technology of halovibrio and polyhydroxyalkanoate, applied in the field of microbiology and fermentation engineering, can solve the problems of limiting the large-scale industrial production and application of PHA, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1, the separation and identification of Salinivibrio kushneri TGB-4

[0063] 1. Separation of Salinivibrio kushneri TGB-4

[0064] Collect water samples from salt ponds in the salt field of Tianjin Binhai New Area. Take 1 mL of water sample and add it to TYS liquid medium containing 20g / L acetic acid, incubate at 30°C and 200rpm for 24h, use a sterilized inoculation loop to streak the TYS solid medium containing 20g / L acetic acid, and incubate for 24h upside down. Pick a single clone and purify it on a TYS solid medium plate. After confirming that it is a pure bacteria, transfer it to a slant for short-term storage at 4°C, and transfer it to a 25% glycerol tube for long-term storage at -80°C. One of the isolated and purified strains TGB-4 is Salinivibrio kushneri TGB-4.

[0065] 2. Identification of Salinivibrio kushneri TGB-4

[0066] (1) Observation of culture traits of strain TGB-4

[0067] After the strain TGB-4 was inoculated on TYS medium and cultured ...

Embodiment 2

[0076] Embodiment 2: Utilize acetic acid to produce polyhydroxyalkanoate

[0077]1. Preparation of Salinivibrio kushneri TGB-4 seed liquid by aseptic operation

[0078] (1) Activation of bacteria

[0079] Take Salinivibrio kushneri TGB-4 glycerol tubes stored in a -80°C refrigerator, streak and inoculate them on TYS solid medium plates, and incubate at 30°C for 16 hours.

[0080] (2) Preparation of seed solution

[0081] Pick a single colony from the plate that has completed step (1), inoculate it in TYS liquid medium, and culture it with shaking at 30° C. and 200 rpm for 12 hours to obtain a seed solution.

[0082] 2. There are two treatments in the experiment: the experimental group and the control group.

[0083] Experimental group: inoculate the seed solution obtained in step 1(2) into 20g / L acetic acid+TYS liquid medium according to the inoculation amount of 2.5% (that is, 1mL of seed solution and 39mL of medium), use a 250mL shake flask, and assemble The liquid volum...

Embodiment 3

[0091] Embodiment 3: Utilize butyric acid to produce polyhydroxyalkanoate

[0092] The specific operation is according to Example 2 of the present invention, the difference is that the medium in the experimental group is a liquid TYS medium containing 15 g / L butyric acid. The culture medium of the control group was liquid TYS medium without butyric acid.

[0093] By calculation, when butyric acid is the carbon source, the dry cell weight is 2.29g / L, and the polyhydroxyalkanoate accumulated in the cell is poly-3-hydroxybutyrate, and the output is 0.92g / L, accounting for 1% of the dry cell weight. The mass fraction is 40.26%.

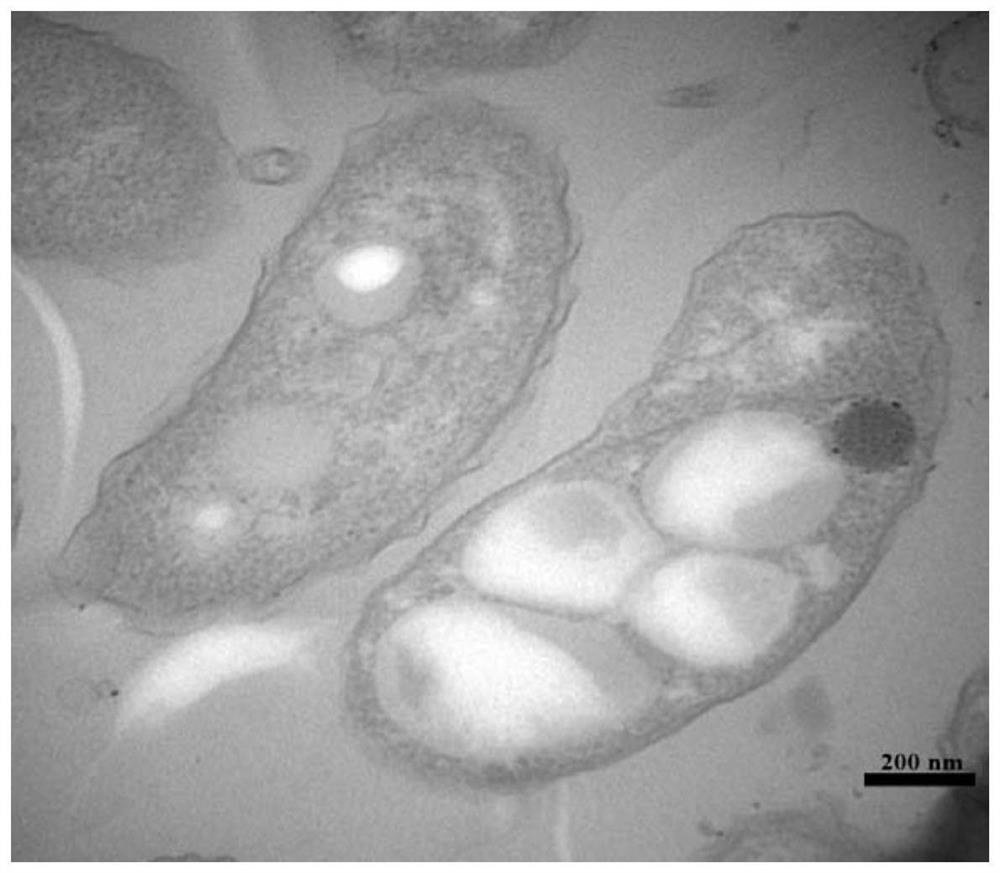

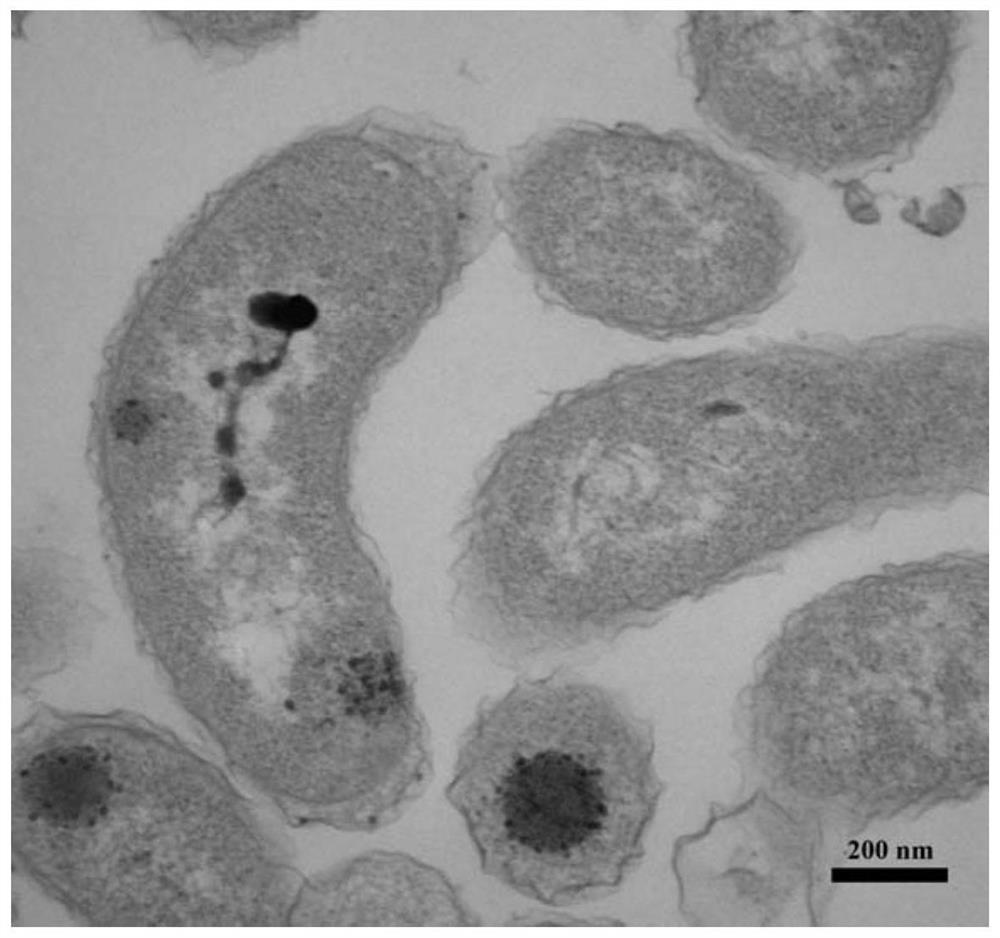

[0094] In addition, utilize transmission electron microscope to observe after the bacteria in embodiment 2 are cultivated, and the results are as follows: figure 1 with figure 2 Shown, where the scale bar is 200nm. figure 1 When butyric acid was used as a carbon source, the bacteria accumulated a large number of white polyhydroxyalkanoate particles i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com