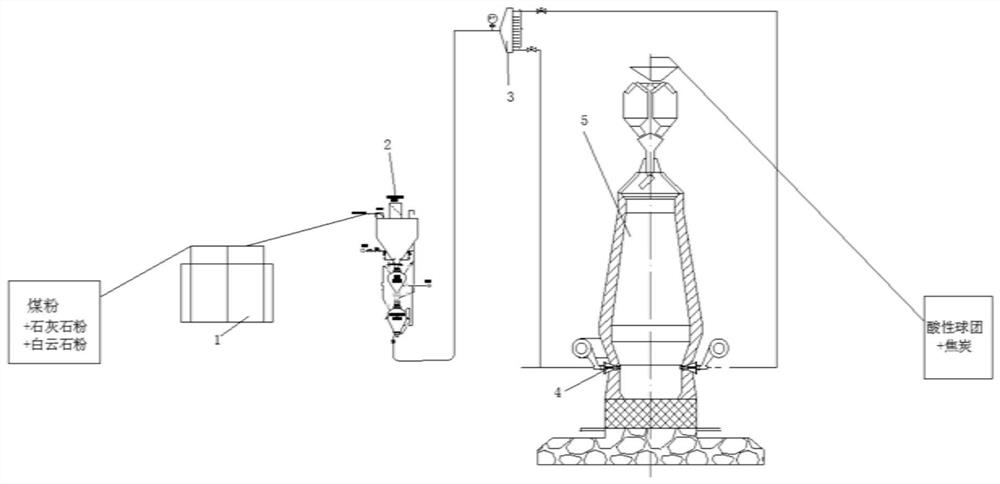

Blast furnace ironmaking method using fully acid pellets as raw material

A blast furnace ironmaking and acidic technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as poor air permeability of blast furnace charge, blast furnace suspended material, collapsed material, and abnormal furnace conditions such as wind stop, so as to achieve good air permeability and avoid The effect of suspending materials and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Taking a 400 vertical blast furnace as an example, the blast furnace hourly material batch is 7 batches, the batch iron amount is 7.32t / p, the batch weight of acid pellets is 12t, the batch weight of coke is 3t, the acid pellets contain 61% iron, slag iron The ratio is 0.32t / tFe, the hourly coal injection rate is 6.5t, the preset value of final slag MgO content is 6%, and the preset value of final slag binary alkalinity is 1.2. Among them, the mass fractions of CaO, SiO2 and MgO in the alkaline solvent, acid pellets, coke and coal powder used are shown in Table 1.

[0059] Table 1

[0060] name limestone powder Dolomite powder acid pellets Coke pulverized coal CaO / % 53.78 34.48 5.7 0.38 2.1 SiO2 / % 0.89 0.84 6.5 6 7.4 MgO / % 0.61 19 0.97 0.1 0.3

[0061] Calculate the injection volume of dolomite powder and limestone powder:

[0062] Hourly injection volume calculation of dolomite powder:

[0063] Hourly dolomite po...

Embodiment 2

[0081] Taking a 400 vertical blast furnace as an example, the batch of blast furnace materials per hour is 7.2 batches, the amount of batch iron is 7.44t / p, the batch weight of acid pellets is 12.2t, the batch weight of coke is 3.6t, and the acid pellets contain 61% iron. The slag-iron ratio is 0.32t / tFe, the hourly coal injection rate is 7t, the preset value of final slag MgO content is 6.5%, and the preset value of final slag binary alkalinity is 1.19. Among them, the mass fractions of CaO, SiO2 and MgO in the alkaline solvent, acid pellets, coke and coal powder used are shown in Table 2.

[0082] Table 2

[0083] name limestone powder Dolomite powder acid pellets Coke pulverized coal CaO / % 53.78 36 4.2 0.38 2.1 SiO2 / % 0.89 0.73 5.1 6 7.4 MgO / % 0.61 20.4 1.1 0.1 0.3

[0084] Calculate the injection volume of dolomite powder and limestone powder:

[0085] Hourly injection volume calculation of dolomite powder:

[0086] ...

Embodiment 3

[0104] Taking a 2500 vertical blast furnace as an example, the blast furnace hourly material batch is 6.5 batches, the batch iron amount is 40.3t / p, the batch weight of acid pellets is 62t, the batch weight of coke is 12.6t, the acid pellets contain 65% iron, and the slag The iron ratio is 0.27t / tFe, the hourly coal injection rate is 38t, the preset value of the MgO content of the final slag is 6.5%, and the preset value of the binary alkalinity of the final slag is 1.22. Among them, the mass fractions of CaO, SiO2 and MgO in the alkaline solvent, acid pellets, coke and coal powder used are shown in Table 3.

[0105] table 3

[0106] name limestone powder Dolomite powder acid pellets Coke pulverized coal CaO / % 53.78 34.48 2.6 0.38 2.1 SiO2 / % 0.89 0.83 3.15 4 6.4 MgO / % 0.61 18 0.97 0.1 0.3

[0107] Calculate the injection volume of dolomite powder and limestone powder:

[0108] Hourly injection volume calculation of dolomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com