Power IGZO thin film transistor and preparation method thereof

A thin-film transistor and power technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as increased on-resistance, reduced current capability, and inability to simultaneously improve the voltage withstand capability and current capability of power devices. Achieve the effect of reducing on-resistance, enhancing controllability, and compensating for current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

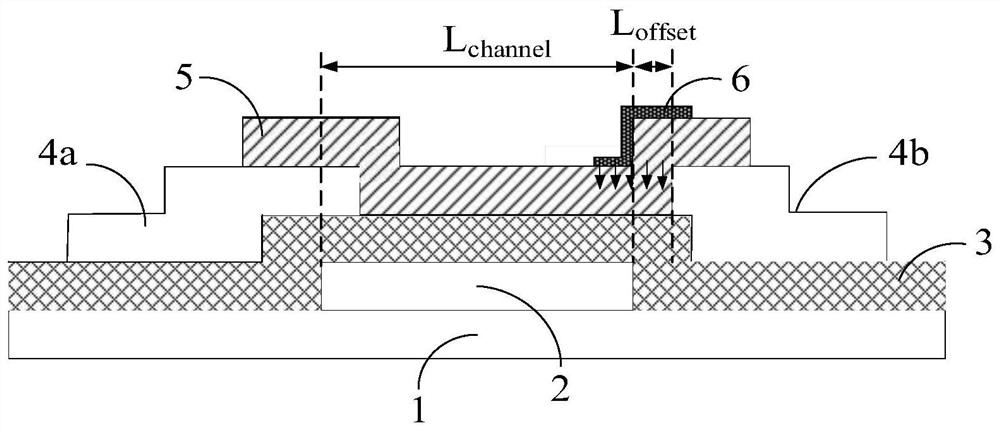

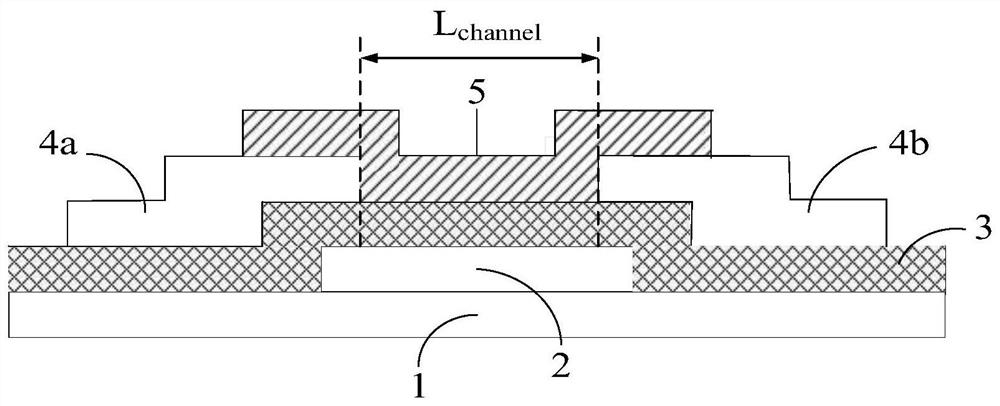

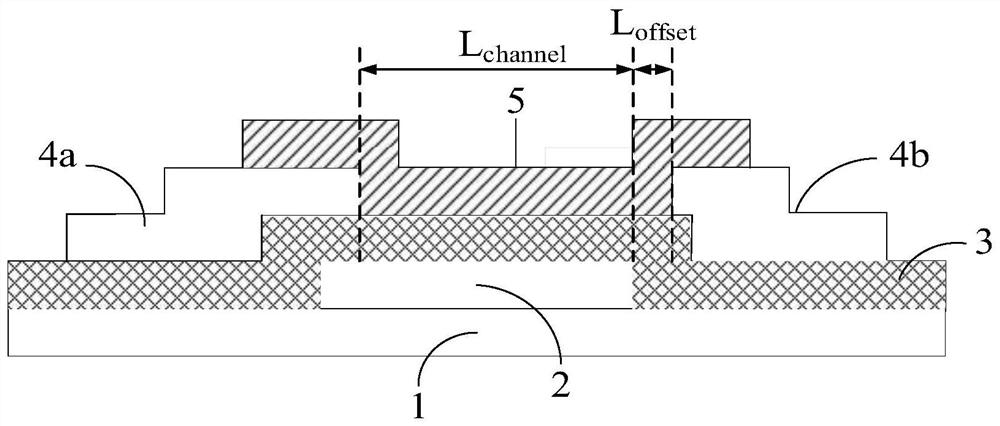

[0028] In order to solve the above problems, the preparation method of a kind of power IGZO thin film transistor of the present invention is as follows:

[0029] The power IGZO thin film transistor of the present invention comprises: obtaining a substrate; forming a gate electrode layer on the substrate; covering a gate insulating layer on the gate electrode layer; forming a source on one side of the gate insulating layer, A drain electrode is formed on the other side; an IGZO active layer is covered on the source electrode and the drain electrode; an Al film covering layer is formed on the IGZO active layer.

[0030] As one of the implementation methods, when depositing the source and drain metal electrodes, the overlap length of the gate electrode layer and the source electrode is 2 μm, and the offset length of the drain electrode is 2 μm through mask pattern design.

[0031] As one of the implementation methods, the Al film capping layer is arranged on the IGZO active layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com