Electroluminescence device with independent electrode structure, preparation method and application

A technology of electroluminescent devices and independent electrodes, which is applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficult environmental stability, avoid decomposition, good repeatability, and high environmental stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

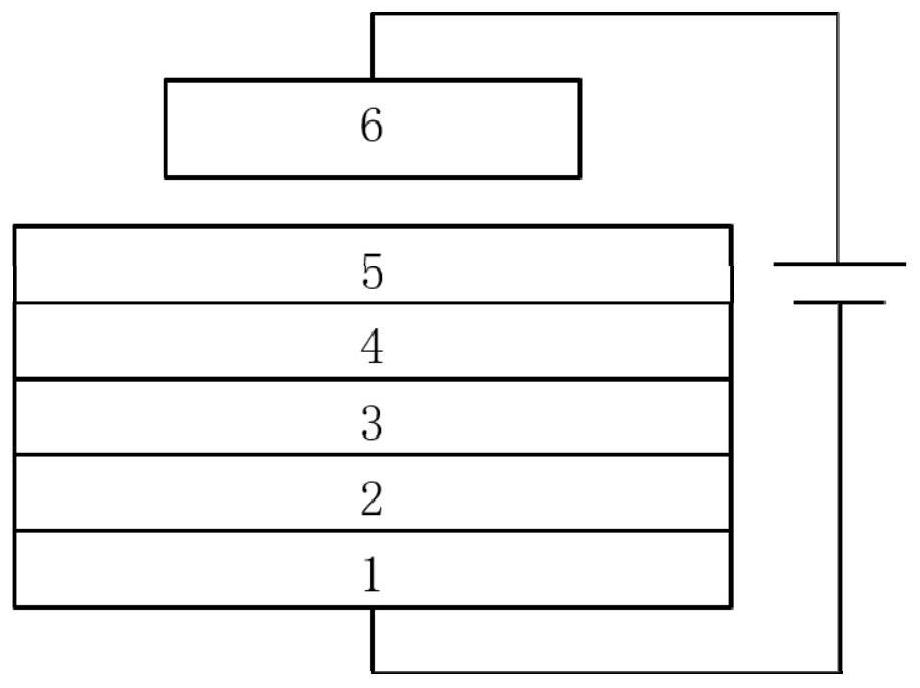

[0050] This embodiment provides an electroluminescent device with an independent electrode structure and a preparation method, including the following steps:

[0051] Step 1: Cleaning of the transparent indium tin oxide (ITO) transparent conductive glass substrate 1: the transparent conductive glass substrate 1 is ultrasonically cleaned with deionized water, acetone, isopropanol and absolute ethanol in sequence for 20 minutes, and nitrogen gas is used before use. The gun is aimed at the transparent conductive glass substrate 1 for drying, and is treated with UV ozone for 15 minutes;

[0052] Step 2: Prepare hole transport layer 2 on transparent conductive glass substrate 1: Prepare smooth and dense hole transport layer 2 of PEDOT:PSS isopropanol solution on transparent conductive glass substrate 1 by spin coating, and apply Annealed on a heating table at 130°C for 20 minutes;

[0053] Step 3: Preparation of perovskite light-emitting layer 3: First, spin-coat a thin film on th...

Embodiment 2

[0058] This embodiment provides an electroluminescent device with an independent electrode structure and a preparation method, including the following steps:

[0059] Step 1: Cleaning of Transparent Tin Oxide Fluoride (FTO) Transparent Conductive Glass Substrate 1: The transparent conductive glass substrate 1 is ultrasonically cleaned with deionized water, acetone, isopropanol and absolute ethanol in sequence for 20 minutes, and nitrogen gas is used before use. The gun is aimed at the transparent conductive glass substrate 1 for drying, and is treated with UV ozone for 15 minutes;

[0060] Step 2: Prepare a hole transport layer 2 on a transparent conductive glass substrate 1: Prepare a smooth and dense PVK hole transport layer 2 on a transparent conductive glass substrate 1 by spin coating, and place it on a heating stage at 130°C Annealing treatment for 20 minutes;

[0061] Step 3: Preparation of perovskite light-emitting layer 3: First, spin-coat a thin film on the hole tra...

Embodiment 3

[0066] This embodiment provides an electroluminescent device with an independent electrode structure and a preparation method, including the following steps:

[0067] Step 1: Cleaning of Transparent Tin Oxide Fluoride (FTO) Transparent Conductive Glass Substrate 1: The transparent conductive glass substrate 1 is ultrasonically cleaned with deionized water, acetone, isopropanol and absolute ethanol in sequence for 20 minutes, and nitrogen gas is used before use. The gun is aimed at the transparent conductive glass substrate 1 for drying, and is treated with UV ozone for 15 minutes;

[0068] Step 2: Prepare hole transport layer 2 on transparent conductive glass substrate 1: Prepare smooth and dense NiO hole transport layer 2 on transparent conductive glass substrate 1 by spin coating, and place it on a heating stage at 130°C Annealing treatment for 20 minutes;

[0069] Step 3: Preparation of perovskite light-emitting layer 3: First, spin-coat a thin film on the hole transport l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com