Preparation method and preparation system of environment-friendly food deoxidizer

A deoxidizer, food technology, applied in food preservation, chemical instruments and methods, food science, etc., can solve problems such as inedibility, and achieve the effect of reducing compound costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

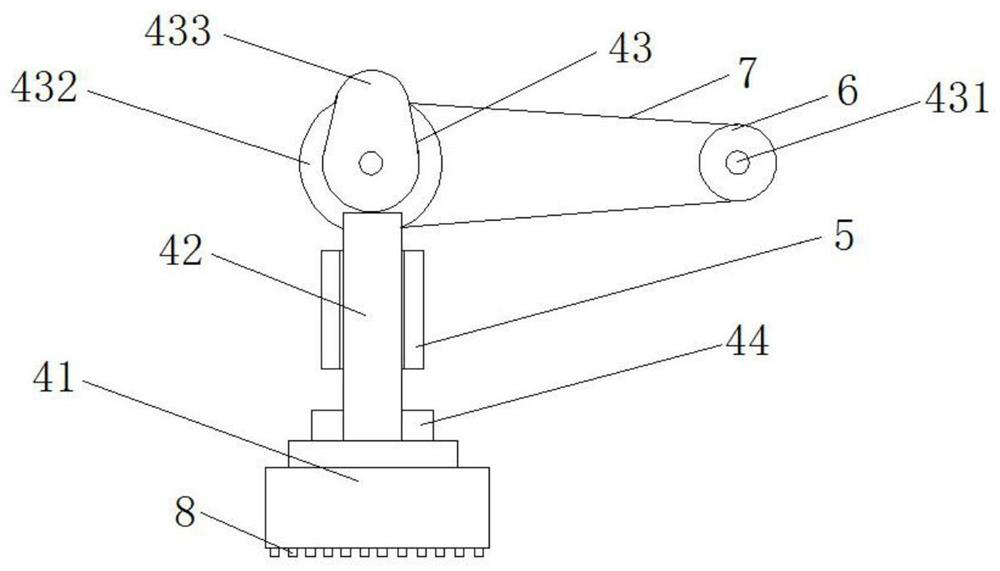

[0061] As a preferred embodiment, the push-down drive assembly 43 includes a drive motor 431, a driven wheel 432 and a cam 433, the drive motor 431 drives the driven wheel 432 to rotate, and the central axis of the driven wheel 432 is connected to the The rotation axis of the cam 433 is coaxial, and the cam 433 is in contact with the upper end of the pressing support rod 42 .

[0062] As a preferred embodiment, a driving wheel 6 is installed on the rotating shaft of the driving motor 431 , and a belt 7 is used for transmission between the driving wheel 6 and the driven wheel 432 .

[0063] As a preferred embodiment, a lamination pattern fusion joint 8 for ultrasonic lamination is distributed on the lower surface of the lower laminate plate 41 .

[0064] As a preferred embodiment, the laminated pattern fusion joint 8 is a matrix sequence, and each pattern unit in the matrix sequence is one of circle, rectangle or oval shape.

[0065] As a preferred embodiment, a limiting plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com