Heavy metal adsorbent as well as preparation method and application thereof

An adsorbent and heavy metal technology, applied in the field of heavy metal adsorbent and its preparation, can solve the problem of small proportion of functional groups and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

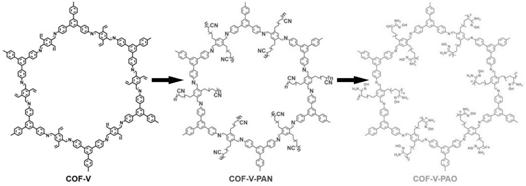

[0041] The preparation method of described heavy metal adsorbent comprises the following steps:

[0042] S12, providing a first monomer and a second monomer, and copolymerizing the first monomer and the second monomer to obtain a covalent organic framework polymer, wherein the first monomer or the second The di-monomer contains at least one cross-linkable carbon-carbon double bond;

[0043] S14, a third monomer is provided, and a cross-linking reaction occurs with the covalent organic framework polymer, and polymer molecular chains are grafted on the covalent organic framework polymer, and the third monomer has at least one cross-linkable linked carbon-carbon double bond and at least one reactive group; and

[0044] S16, providing a modifier, and reacting with the polymer molecular chain to obtain a covalent organic framework material, wherein the modifier is a compound containing a functional group that can adsorb heavy metals, and all the compounds in the third monomer The...

Embodiment 1

[0073] Embodiment 1 Preparation of COF-V-PAO containing amidoxime group

[0074]

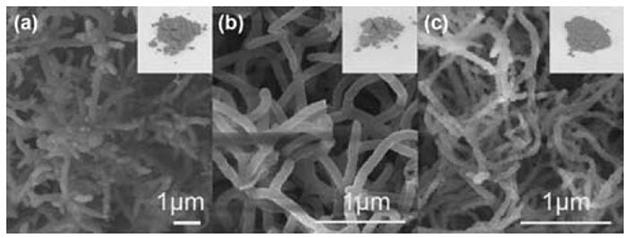

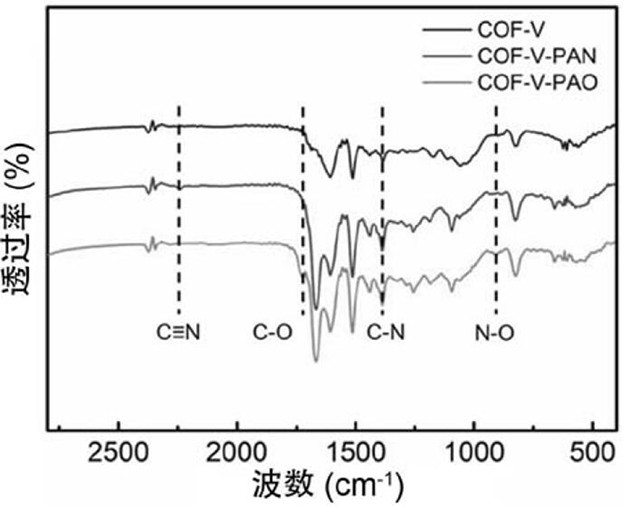

[0075] (1) Construction of vinyl-containing covalent organic frameworks

[0076] Weigh 22.3 mg of 1,4-dialdehyde-2,5-divinylbenzene and 28.0 mg of 1,3,5-tris(4-aminophenyl)benzene into a miniature pressure-resistant reactor, and then add 0.5 mL of n-butanol and 0.5 mL of 1,2-dichlorobenzene, the mixed cloudy solution was ultrasonicated until uniformly mixed, and then 0.1 mL of acetic acid solution with a concentration of 6 mol / L was added as a catalyst.

[0077] Place the miniature pressure-resistant reactor in liquid nitrogen to cool until it solidifies, then vacuumize the reactor and backfill it with argon. The above process of cooling-vacuumizing-backfilling with argon is repeated three times, and then the reaction system is sealed. After the mixed solution inside the glass tube reached room temperature, it was placed in an oven at 100 °C for 72 h.

[0078] After the reaction was complet...

Embodiment 2

[0084] Preparation of COF-V-PAO-0.5 grafted with shorter polymer molecular chains in Example 2

[0085] The preparation method of Example 2 is basically the same as that of Example 1, except that less acrylonitrile monomer is added in step (2), that is, the addition of 3.72 mL of acrylonitrile in step (2) in Example 1 is replaced by adding 1.86 mL of acrylonitrile was used to obtain the covalent organic framework adsorbent COF-V-PAO-0.5, and the degree of polymerization of the polymer molecular chain grafted on COF-V-PAN-0.5 was 62. Nitrogen adsorption and desorption experiments show that the specific surface area of COF-V-PAO-0.5 is 761 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com