Adsorbing material for blood purification and preparation method thereof

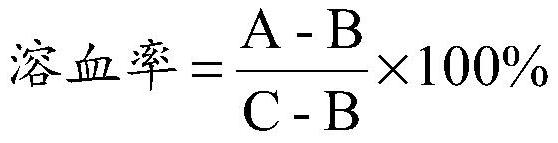

A technology of adsorption material and adsorption resin, which is applied in the fields of biochemical separation and biomedical materials, and achieves the effects of low hemolysis rate, improved safety, and strong adsorption and removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

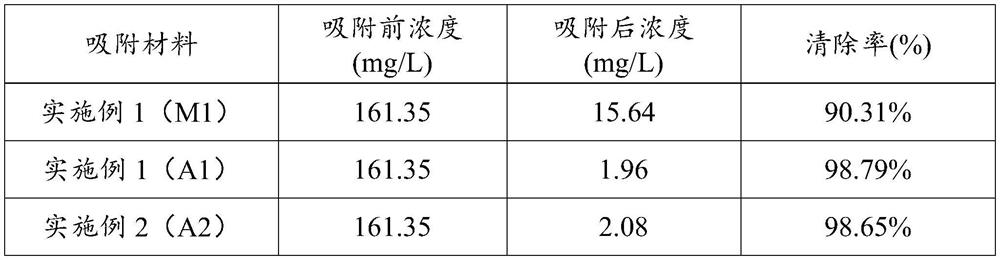

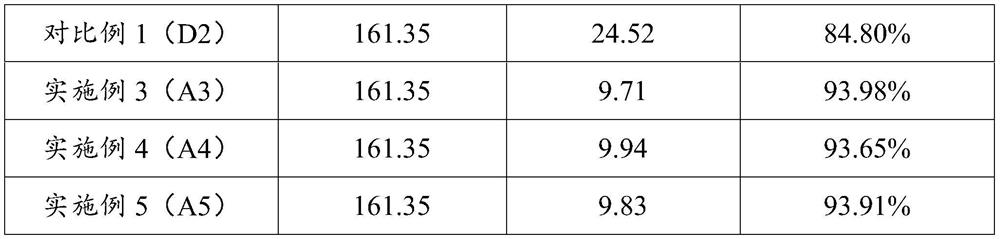

Examples

Embodiment 1

[0041] S1. Synthetic adsorption resin microspheres:

[0042] Heat and dissolve 5g of gelatin in purified water, add 40g of styrene, 55g of divinylbenzene, 3g of benzoyl peroxide, 160g of toluene, 20g of isooctane, an appropriate amount of liquid paraffin and 6g of vinylpyrrolidone, stir well, and then Add 0.6 g of calcium phosphate, gradually raise the temperature to 75°C, and set the shape for 3 hours to obtain pre-microspheres, which are then subjected to suspension polymerization at 80°C for 24 hours to prepare adsorption resin microspheres M1;

[0043]S2. Modification of adsorption resin microspheres:

[0044] The modification method of the adsorption resin microspheres M1 in this embodiment is double bond epoxidation modification, and the modification steps are: take 10 g of the adsorption resin microspheres M1, add 40 mL of dichloroethane to soak for 24 hours, drop by drop Add 20 mL of 10% m-chloroperoxybenzoic acid dichloride ethane solution, stir in an ice-water bath ...

Embodiment 2

[0048] S1. Synthetic adsorption resin microspheres:

[0049] Heat and dissolve 4g of gelatin in purified water, add 50g of styrene, 45g of divinylbenzene, 2g of benzoyl peroxide, 175g of toluene, 25g of isooctane and 7g of hydroxyethyl methacrylate, stir well, and then add Calcium phosphate 0.5g, gradually raise the temperature to 75°C, and set the shape for 2 hours to obtain the pre-microspheres, and continue to carry out the suspension polymerization reaction at 80°C for 24 hours to prepare the adsorption resin microspheres M2;

[0050] S2. Modification of adsorption resin microspheres:

[0051] The modification method of the adsorption resin microspheres M2 in this embodiment is double bond epoxidation modification, and the modification steps are: take 10 g of the adsorption resin microspheres M2, add 40 mL of dichloroethane to soak for 24 hours, drop by drop Add 5mL of 30% hydrogen peroxide and 5g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), stir ...

Embodiment 3

[0062] S1. Synthetic adsorption resin microspheres:

[0063] Take 3g of polyvinyl alcohol and dissolve it in purified water, add 45g of styrene, 50g of divinylbenzene, 4g of benzoyl peroxide, 124g of toluene, 53g of isooctane and 4g of methacryloyloxyethylphosphorylcholine , after stirring evenly, gradually raise the temperature to 75°C, set the shape for 3 hours to obtain pre-microspheres, and continue to carry out the suspension polymerization reaction of the pre-microspheres at 80°C for 24 hours to prepare the adsorption resin microspheres M3;

[0064] S2. Modification of adsorption resin microspheres:

[0065] The modification method of the adsorption resin microspheres M3 in this comparative example is the chloromethylation modification of the benzene ring. The modification steps are: take 10 g of the adsorption resin microspheres M3 and add them to 40 mL of chloromethyl ether solution to swell for 2 hours, then add 6 g Zinc chloride was heated to 42°C, and the chloromet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com