Flue gas secondary combustion and high-temperature filtering dust removal integrated device and process

A secondary combustion, filtration and dust removal technology, applied in the direction of combustion method, combined device, combustion type, etc., can solve the problems of unstable combustion operation, easy dust accumulation in pipelines, poor economy, etc., to promote full decomposition and improve filtration efficiency , the effect of increasing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

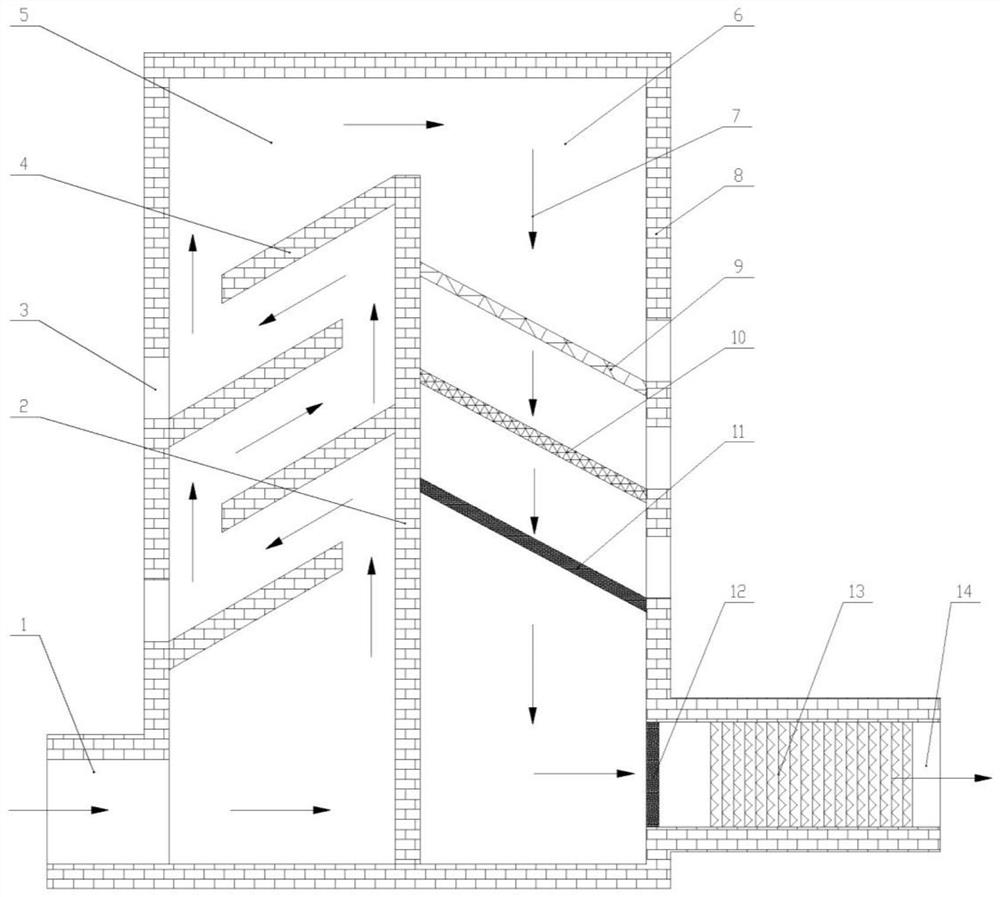

[0042] Such as figure 2 As shown, the flue gas secondary combustion and high-temperature filtration and dust removal integrated device of this embodiment includes a furnace chamber 8, the bottom of the furnace chamber 8 is provided with a sub-chamber 2, and the sub-cavity board 2 divides the furnace chamber 8 into an upper part Combustion settling area 5 and filter area 6 communicated with each other, multiple groups of deflectors 4 are arranged on the side walls in the combustion settling area 5, filter assemblies are arranged between the side walls in the filter area 6, the The lower part of the furnace chamber 8 is provided with a flue gas inlet 1 on the side close to the combustion settling area 5 , and a flue gas outlet 14 is opened on the side close to the filtering area 6 .

[0043] The present invention adopts the cavity plate 2 to separate the furnace chamber 8 of the device into a combustion settlement area 5 and a filter area 6, and a flue gas inlet 1 is provided a...

Embodiment 2

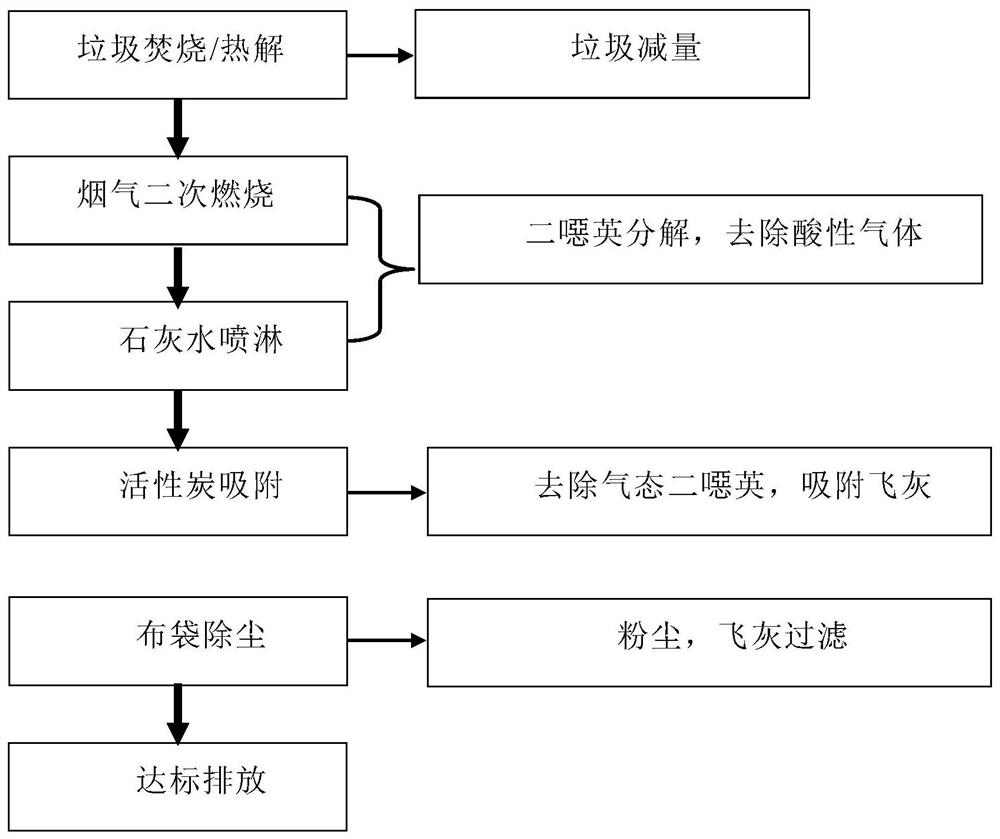

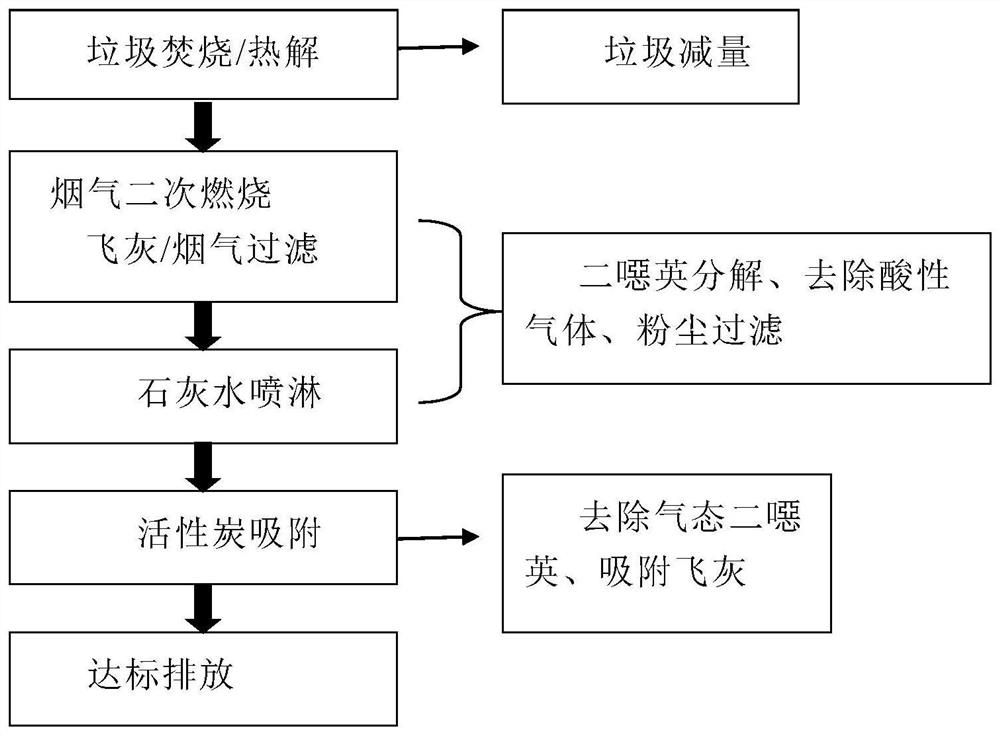

[0061] Such as image 3 As shown, this embodiment includes the following steps:

[0062] Step 1. Incinerate or pyrolyze the garbage to form flue gas;

[0063]Step 2. The flue gas formed in step 1 is sent to the flue gas secondary combustion and high-temperature filtration and dust removal integrated device, and the secondary combustion and high-temperature filtration and dust removal are carried out at above 850°C to obtain dust-removed high-temperature flue gas;

[0064] Step 3, performing deacidification on the dedusting high-temperature flue gas obtained in step 2 by spraying with lime water to obtain deacidification gas;

[0065] Step 4: Adsorb the acid-removing gas obtained in Step 3 with activated carbon to obtain standard flue gas and discharge it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com