Aluminum alloy processing technology optimization method and application thereof

An optimization method and processing technology technology, applied in design optimization/simulation, special data processing applications, manufacturing tools, etc., can solve problems such as complex process, discontinuous growth, and difficult experimental design, so as to achieve no secondary crystallization, microstructure The effect of uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The optimized processing parameters of aluminum alloys are determined through the process described in the detailed description, including: isothermal compression experiments:

[0067] The pure aluminum series 6082 aluminum alloy was selected as the sample, and its main chemical composition is shown in Table 1 below:

[0068] Table 1: Main chemical composition of 6082 aluminum alloy

[0069]

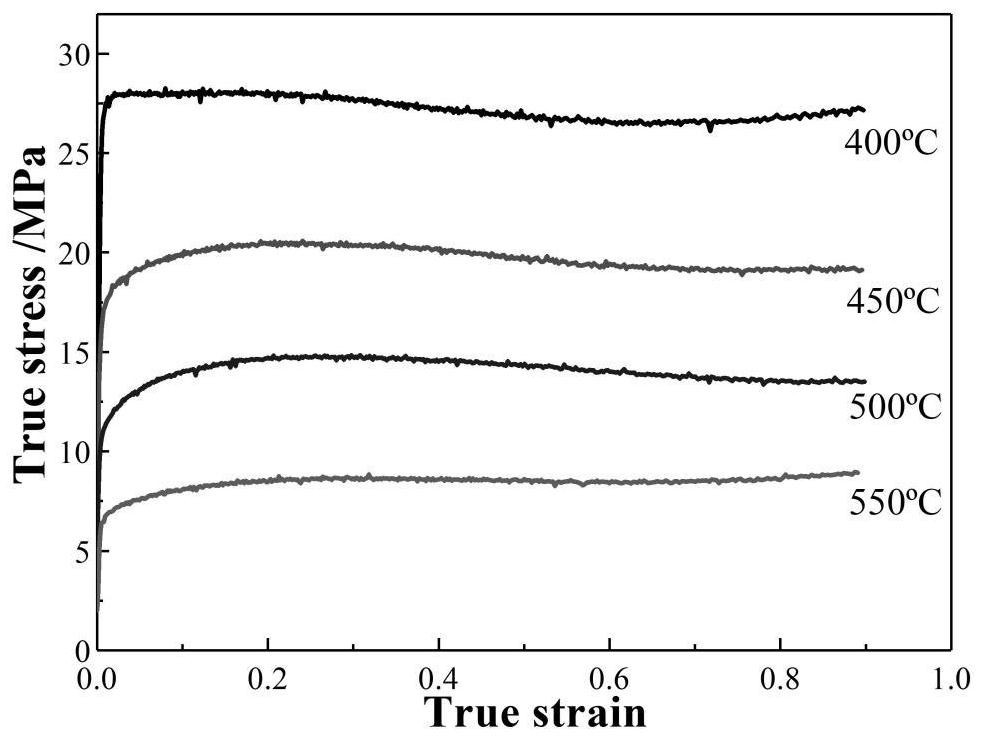

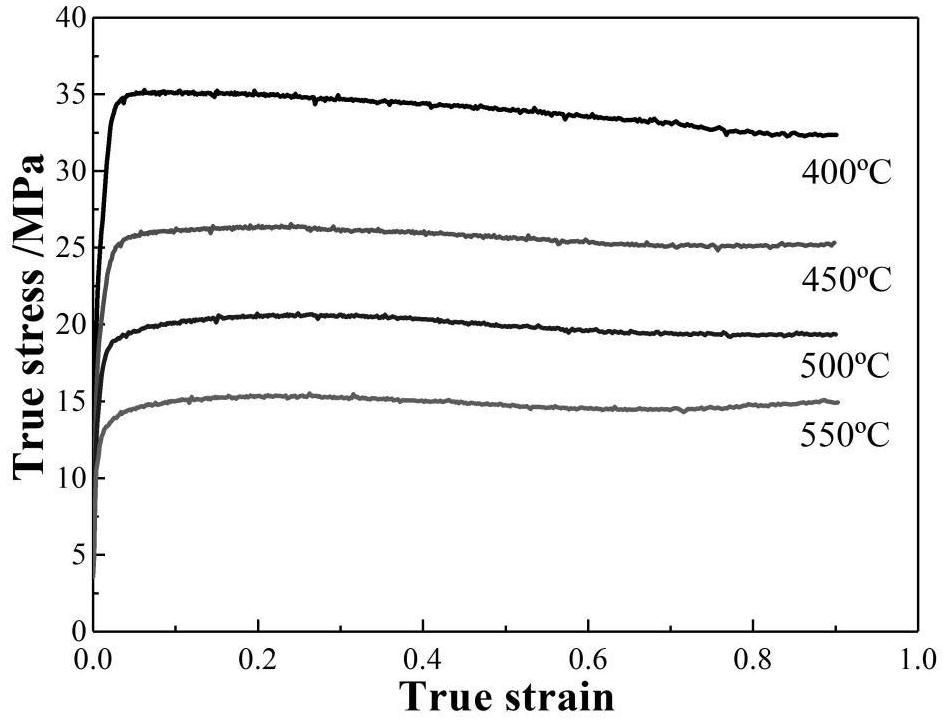

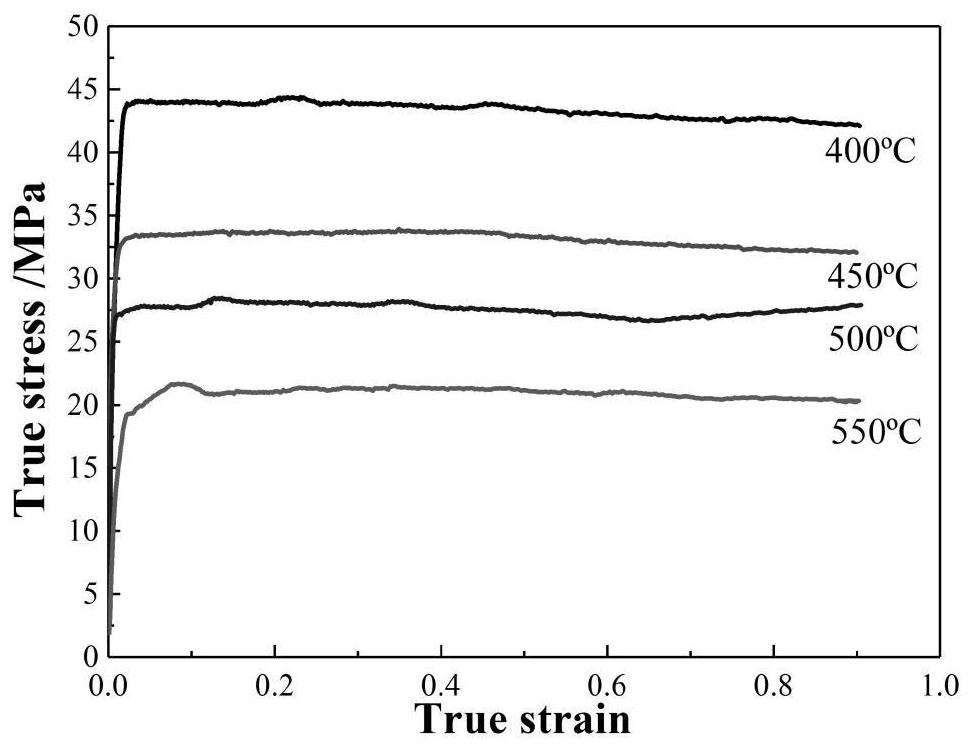

[0070] The aluminum alloy is processed into a cylindrical thermal compression sample of Φ10×15mm, and the dynamic thermal simulation test machine is selected as Gleeble-3500. Both ends of the sample are coated with 90% oleic acid and 10% paraffin as lubricants to Reduce the effects of friction. To ensure uniform temperature distribution, the samples were heated to the set temperature at a heating rate of 5 °C / s and kept for 3 min before compression. At a strain rate of 0.001s -1 、0.01s -1 , 0.1s -1 and 1s -1 , under the conditions of 400°C, 450°C, 500°C and 550°C, the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com