Method for forming ohmic contact to P-type silicon carbide

An ohmic contact, silicon carbide layer technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

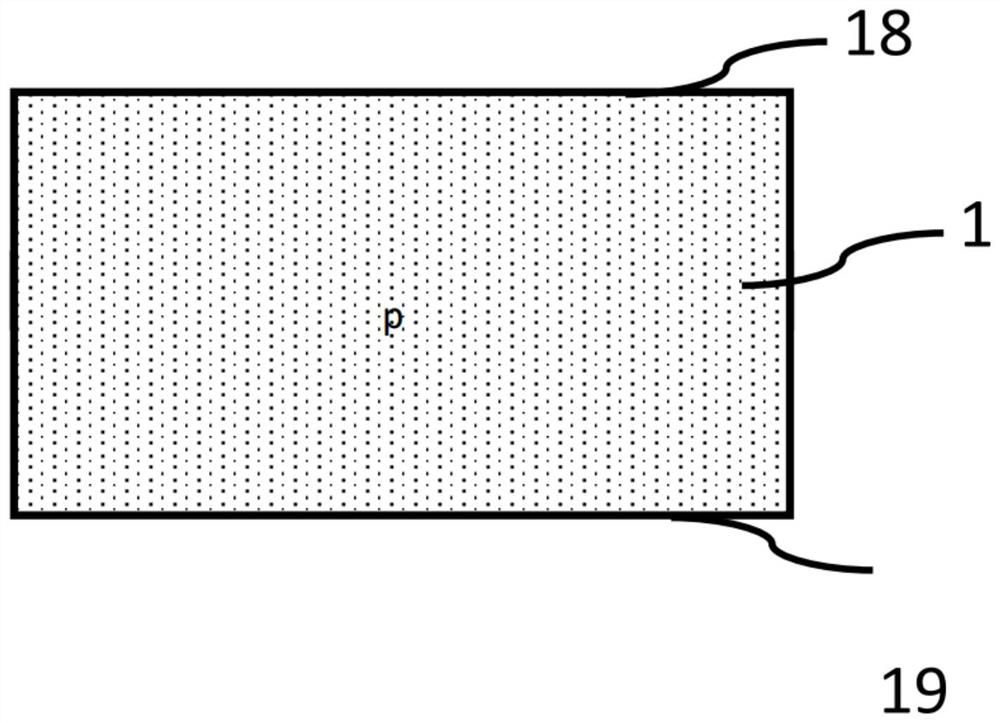

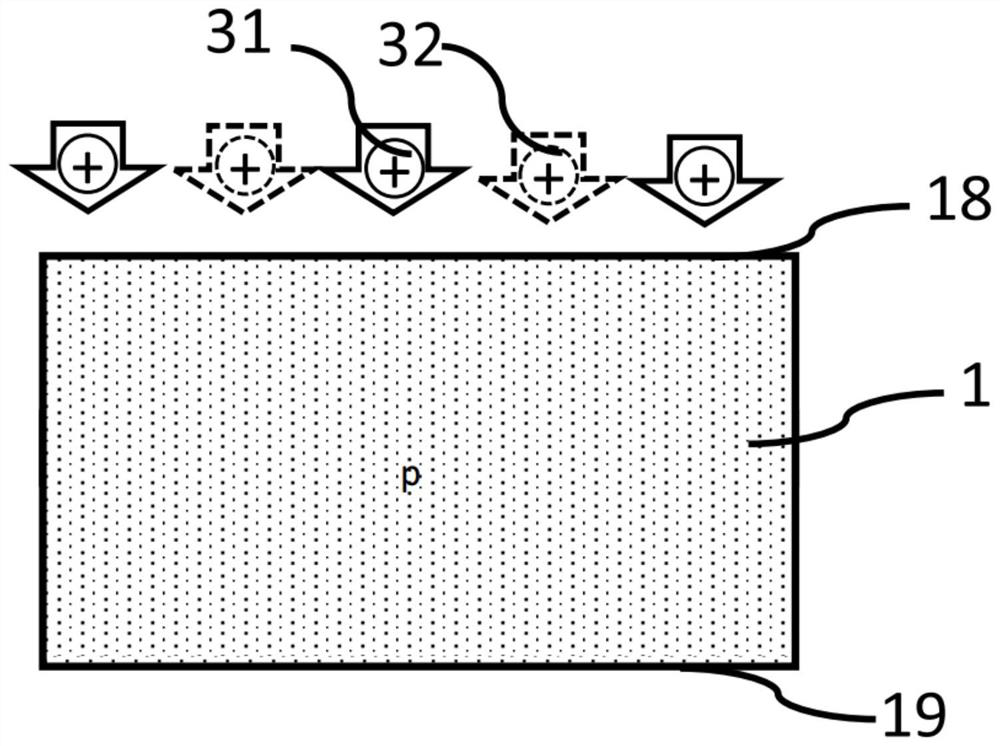

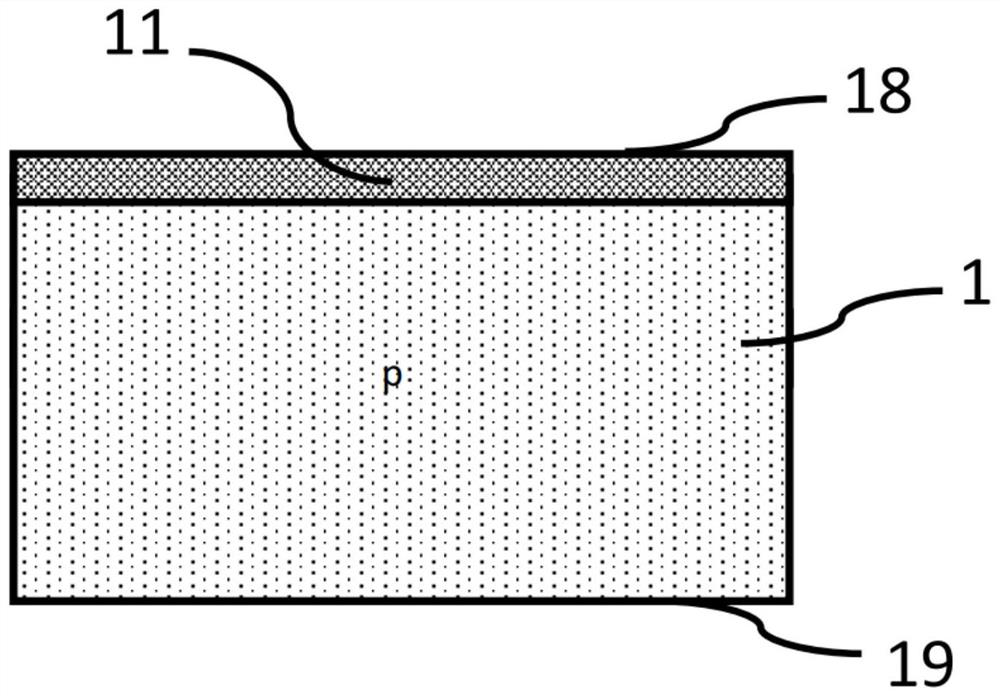

[0047] Figures 1A-1D Shown are steps of a method of forming an ohmic contact with a p-type silicon carbide layer according to an example embodiment. exist Figure 1AIn the first step shown, a p-type silicon carbide layer 1 is provided having a first main side 18 and a second main side 19 opposite to the first main side. The p-type silicon carbide layer 1 may include bulk monocrystalline and / or epitaxial layers, and may be of any polytype bulk structure, such as 4H-SiC or 6H-SiC. The p-type silicon carbide layer 1 is for example doped with aluminum and / or boron. The p-type doping of the p-type silicon carbide layer 1 can be performed by any known method, such as ion implantation, co-doping during growth by including a p-type dopant source gas in the growth chamber, in the undoped carbon Dopants are deposited (eg, by sputtering, chemical vapor deposition, evaporation, etc.) on the silicon layer followed by annealing to diffuse the dopants into the undoped silicon carbide laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com