Manufacturing method of low-cost island structure LTCC substrate

A manufacturing method and low-cost technology are applied in the manufacturing field of low-cost island structure LTCC substrates, which can solve the problems of high limit cost of green ceramic tapes, low strength of green ceramic tapes, waste of green ceramic structures, etc., and achieve dimensional stability and cost. Low, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] A method for manufacturing a low-cost island structure LTCC substrate, comprising the following steps:

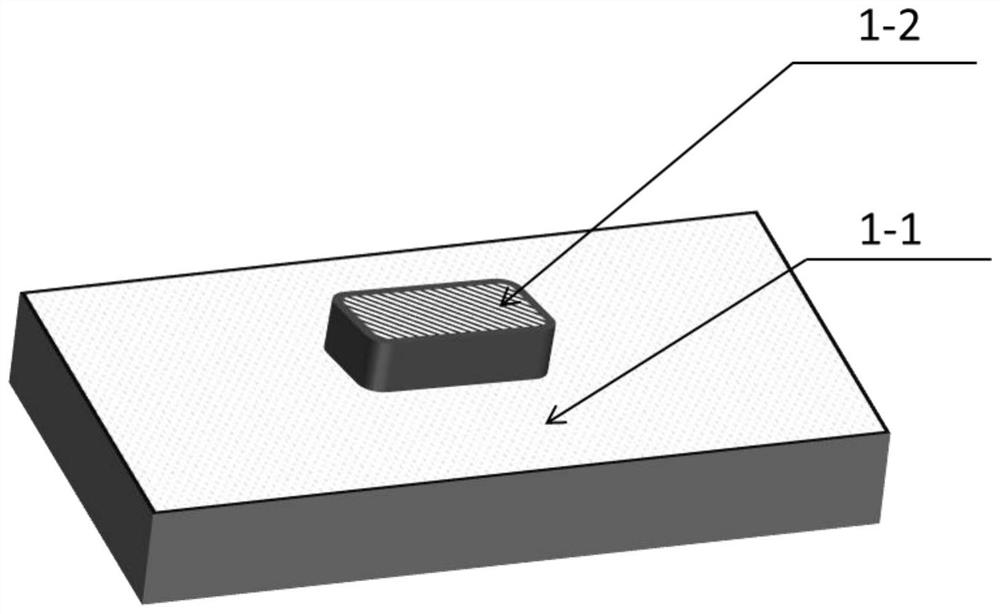

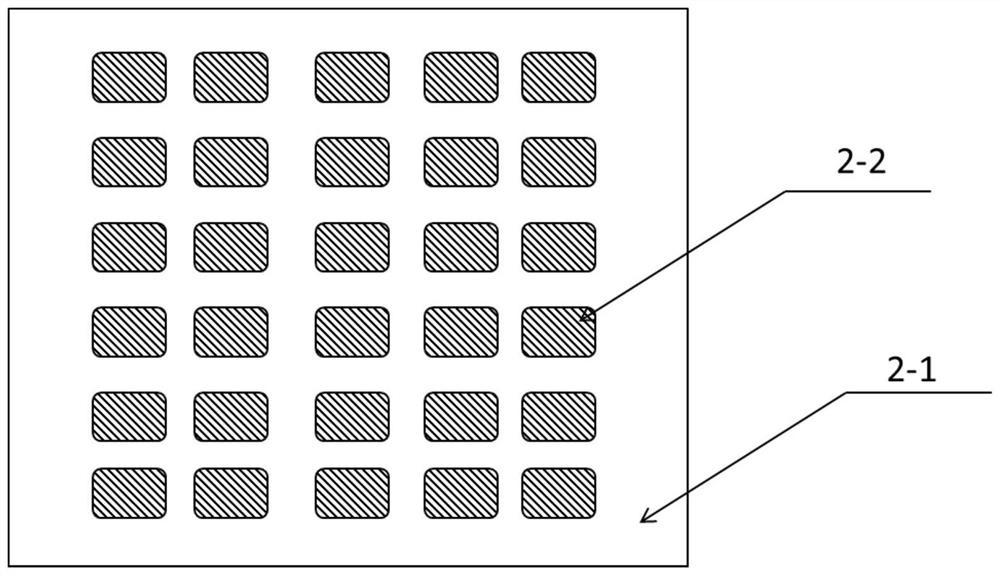

[0034] (1) According to the product design structure, the product is typesetting and designed according to the island structure and the base structure;

[0035] (2) Cutting, aging, punching, filling and printing operations layer by layer according to the product layer design requirements;

[0036] (3) Carry out the first lamination and hot pressing of the island structure and the base structure respectively to obtain the corresponding green body;

[0037] (4) Cut the hot-pressed island green body into individual small units by means of laser or eager cutting;

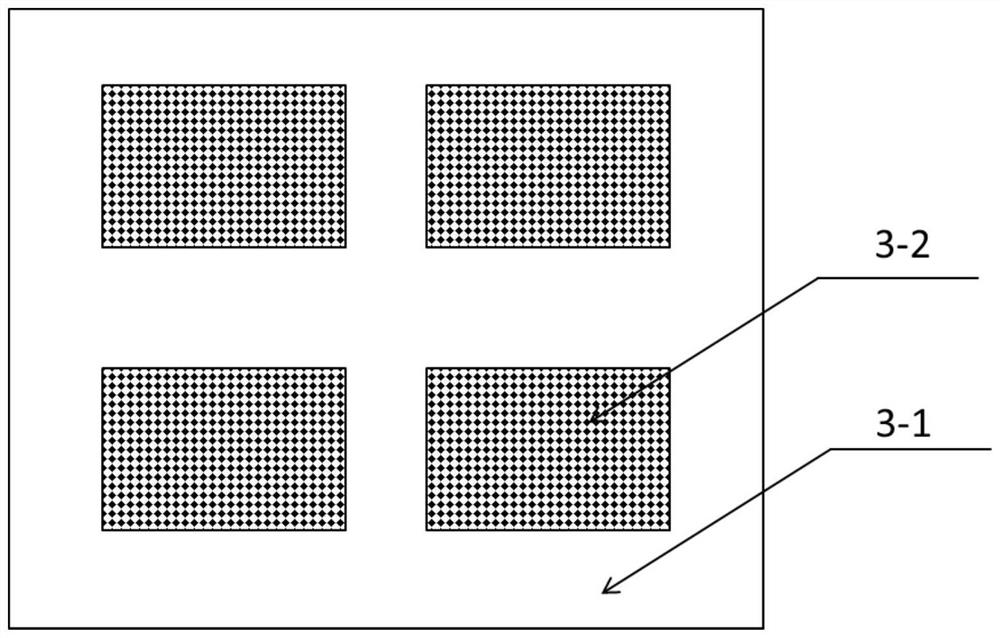

[0038] (5) Process a PET film with a cavity inside by laser or mechanical punching machine, and the position corresponding to the cavity is an island structure;

[0039] (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com