An electrochemical water treatment device with descaling function

A water treatment equipment, electrochemical technology, applied in electrochemical water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It is immature and cannot guarantee the descaling performance of the equipment, so as to achieve the effect of enhancing the cathode descaling performance, promoting dendritic growth, and improving the hydrophobicity of the fiber surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

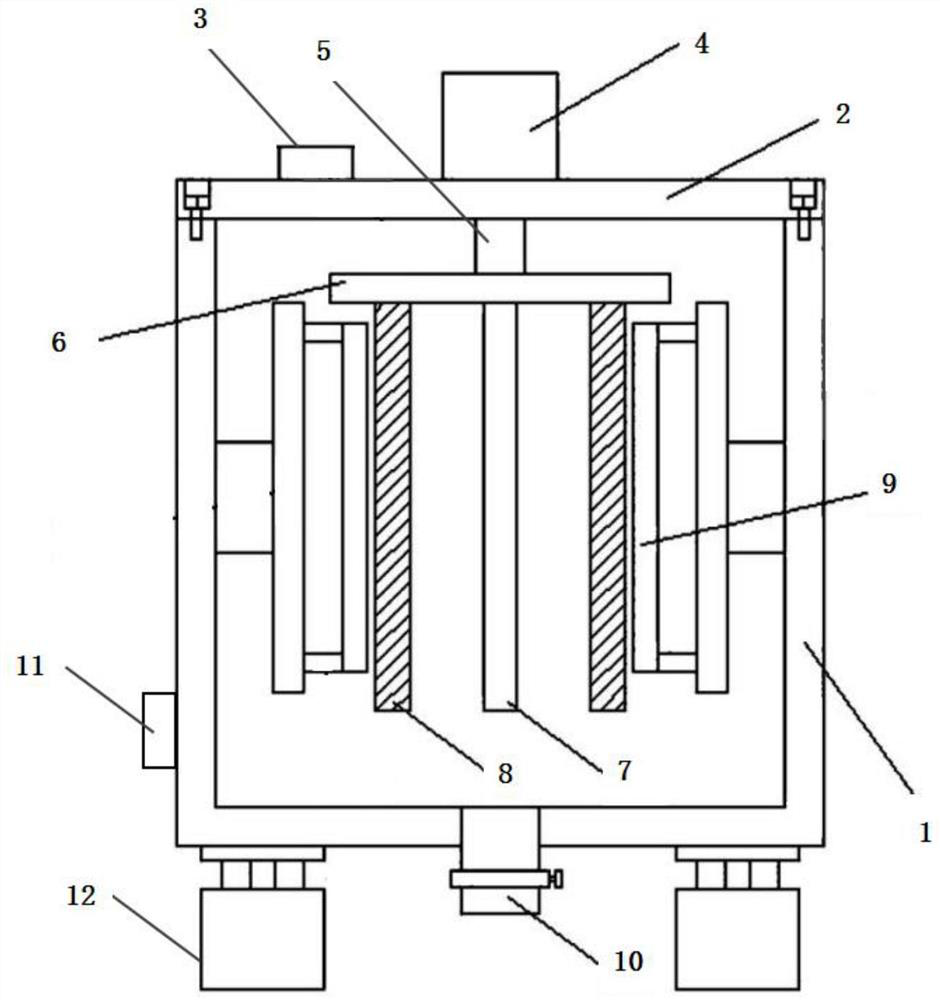

[0034] An electrochemical water treatment device with descaling function, comprising a cylinder body and a cover body arranged on the top of the cylinder body, the cover body is connected with the top of the cylinder body through detachable bolts on the cover body A water inlet is opened, a rotating motor is fixedly connected to the upper end of the cover body, and the output end of the rotating motor is fixedly connected to a rotating shaft arranged in the cylinder and drives the rotating shaft to rotate, and the rotating shaft is away from the rotation. One end of the motor is fixedly provided with an extension circular plate, an anode and at least two cathodes are fixedly arranged in parallel on the extension circular plate, the anodes are arranged at the center of the extension circular plate, and the cathodes are arranged symmetrically at the at the edge of the extended circular plate; an electrode scraper is fixed on the inner wall of the cylinder, and a sewage outlet and...

Embodiment 2

[0037] An electrochemical water treatment device with descaling function, comprising a cylinder body and a cover body arranged on the top of the cylinder body, the cover body is connected with the top of the cylinder body through detachable bolts on the cover body A water inlet is opened, a rotating motor is fixedly connected to the upper end of the cover body, and the output end of the rotating motor is fixedly connected to a rotating shaft arranged in the cylinder and drives the rotating shaft to rotate, and the rotating shaft is away from the rotation. One end of the motor is fixedly provided with an extension circular plate, an anode and at least two cathodes are fixedly arranged in parallel on the extension circular plate, the anodes are arranged at the center of the extension circular plate, and the cathodes are arranged symmetrically at the at the edge of the extended circular plate; an electrode scraper is fixed on the inner wall of the cylinder, and a sewage outlet and...

Embodiment 3

[0048] An electrochemical water treatment device with descaling function, comprising a cylinder body and a cover body arranged on the top of the cylinder body, the cover body is connected with the top of the cylinder body through detachable bolts on the cover body A water inlet is opened, a rotating motor is fixedly connected to the upper end of the cover body, and the output end of the rotating motor is fixedly connected to a rotating shaft arranged in the cylinder and drives the rotating shaft to rotate, and the rotating shaft is away from the rotation. One end of the motor is fixedly provided with an extension circular plate, an anode and at least two cathodes are fixedly arranged in parallel on the extension circular plate, the anodes are arranged at the center of the extension circular plate, and the cathodes are arranged symmetrically at the at the edge of the extended circular plate; an electrode scraper is fixed on the inner wall of the cylinder, and a sewage outlet and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com