Metamaterial spunbond cloth and preparation method thereof

A technology of metamaterials and spunbond fabrics, applied in the field of material manufacturing, which can solve the problems of limiting human comfort, poor air permeability of multi-layer membrane structures, and reducing human body heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

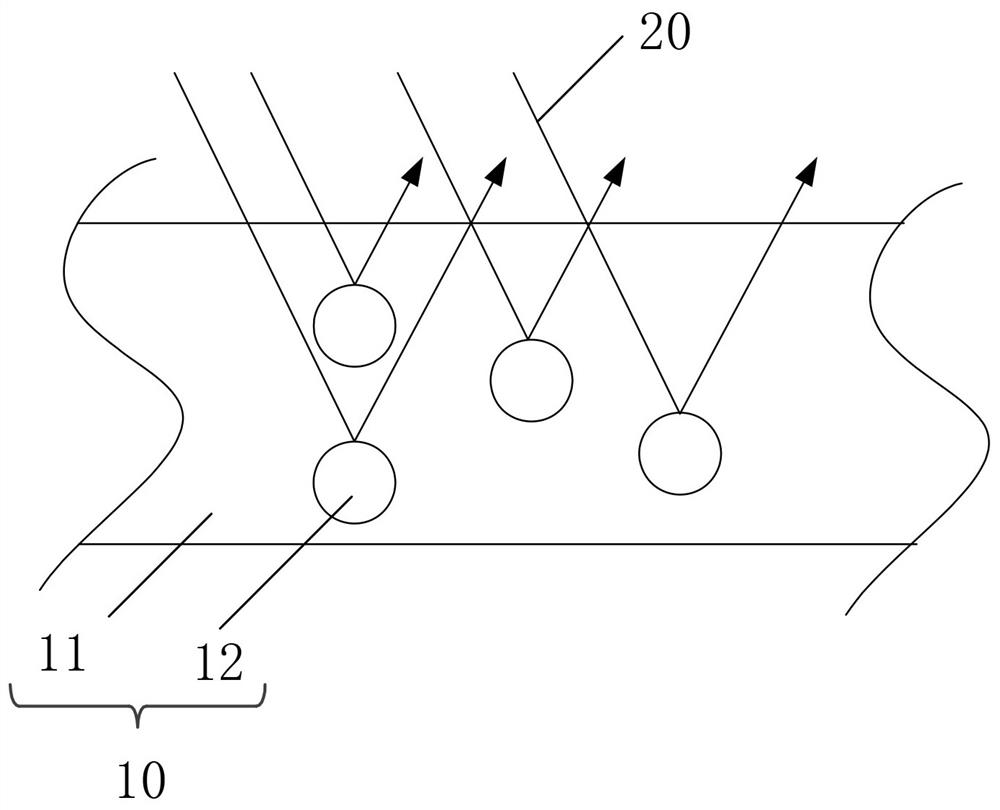

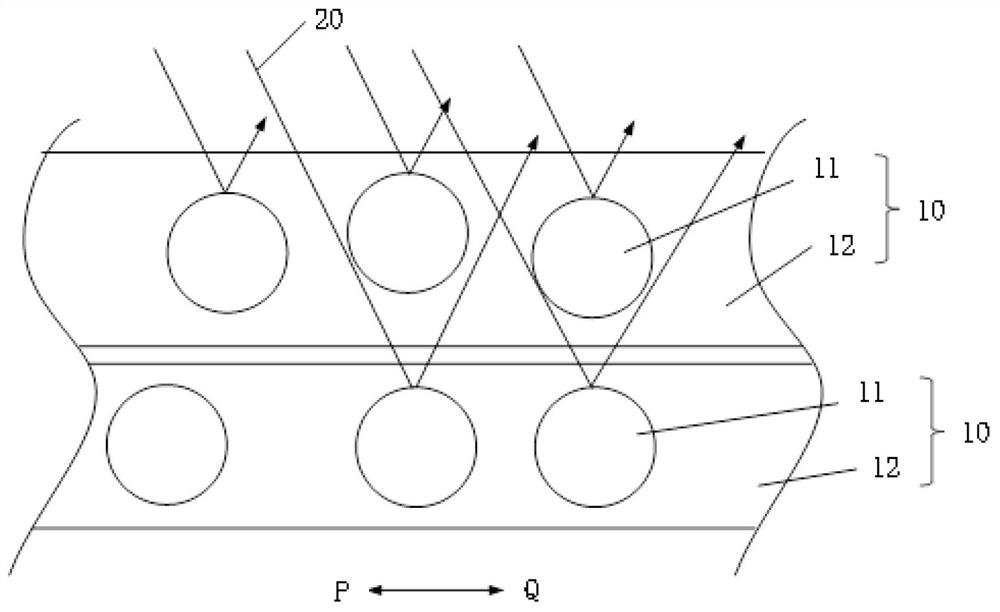

[0080] According to the second aspect of the present application, a method for preparing a supermaterial spunbonded cloth is provided, the preparation method comprising:

[0081] Step 1: mixing the polymer base material and micro-nano particles to form a full-spectrum reflective composite material, the average particle size of the micro-nano particles is 100-3000nm;

[0082] Step 2: Extruding the full-spectrum reflective composite material through a melt-blown die to form a thin stream of melt;

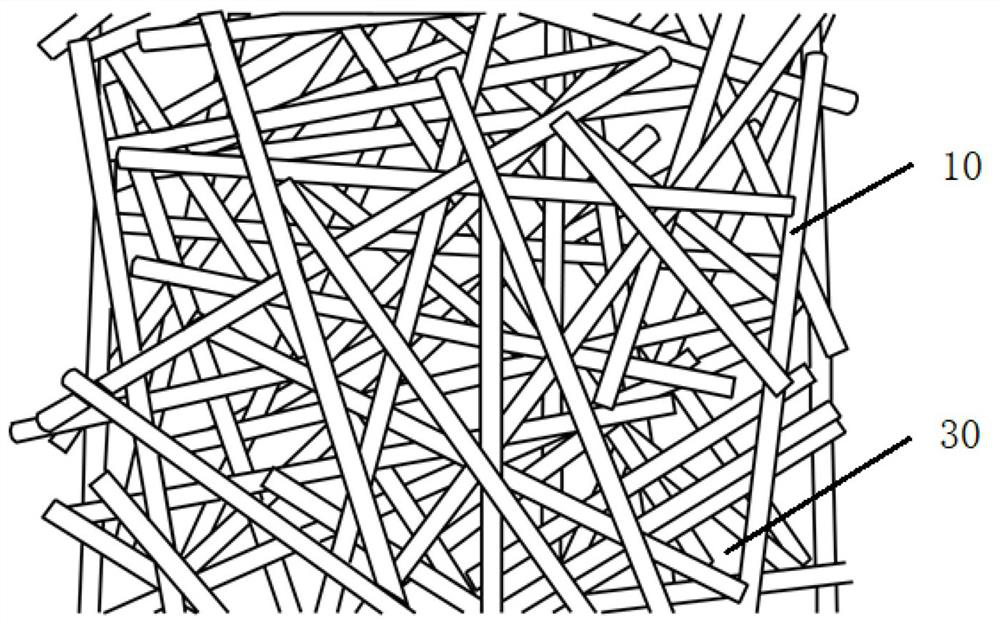

[0083] Step 3: The melt stream meets the high-speed hot air flow at the outlet of the melt-blown die head, the melt stream is drawn and refined by the high-speed hot air stream, and spun to obtain supermaterial fibers. The supermaterial fibers evenly fall on the roller of the receiving device to form a supermaterial spunbond fabric.

[0084] In a specific embodiment, after the full-spectrum reflective composite material is mixed, it can be cooled for use. When necessary, the full-sp...

Embodiment 1

[0109] 600g of PET particles and 400g of TiO with a particle size of 0.1μm 2 After the particles are mixed, they are added to the feed port of the twin-screw extruder, and the heating temperature is set to 280°C. The extruded molten casting belt is solidified in a normal temperature water bath, and the casting belt passes through the guide wheel to the slicer for pelletizing to obtain inorganic micro-nano particle doping 40% full spectrum reflective composite.

[0110] After the composite material is dried, it is put into a large screw for melting and extrusion, and the heating temperature is set to 290°C. The extruded melt is filtered through a melt filter, and is quantitatively transported by a metering pump at a speed of 15r / min for spinning and cooling. The supermaterial fibers are obtained by airflow traction and formed into a web on a mesh curtain with a receiving distance of 60cm. The winding speed of the roller curtain roller is 30m / min; the rolling mill is used for ho...

Embodiment 2

[0112] 600g of PLA particles and 400g of TiO with a particle size of 0.2μm 2 After the particles are mixed, they are added to the feed port of the twin-screw extruder, and the heating temperature is set to 200°C. The extruded molten casting belt is solidified in a normal temperature water bath, and the casting belt is passed through the guide wheel to the slicer for pelletizing, and inorganic micro-nano particle doping is obtained. 40% full spectrum reflective composite.

[0113] After the composite material is dried, it is put into a large screw for melting and extrusion, and the heating temperature is set to 210°C. The extruded melt is filtered through a melt filter, and is quantitatively transported by a metering pump at a speed of 15r / min for spinning and cooling. The supermaterial fibers are obtained by airflow traction and formed into a web on a mesh curtain with a receiving distance of 60cm. The winding speed of the roller curtain roller is 30m / min; the rolling mill is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com