Unattended vacuum stability experiment testing device, system and method

A technology for vacuum stability and experimental testing, applied in the field of thermal performance detection of explosives for weapons, can solve the problems of high safety risk, manpower consumption, low detection efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

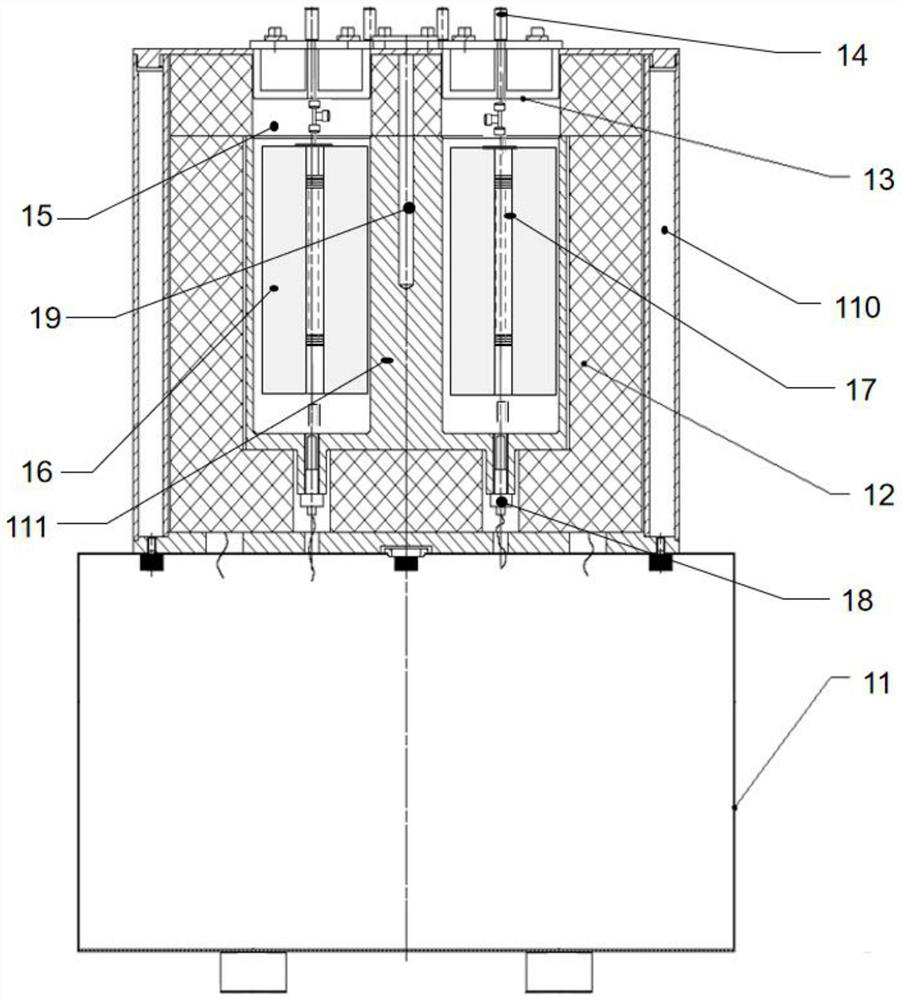

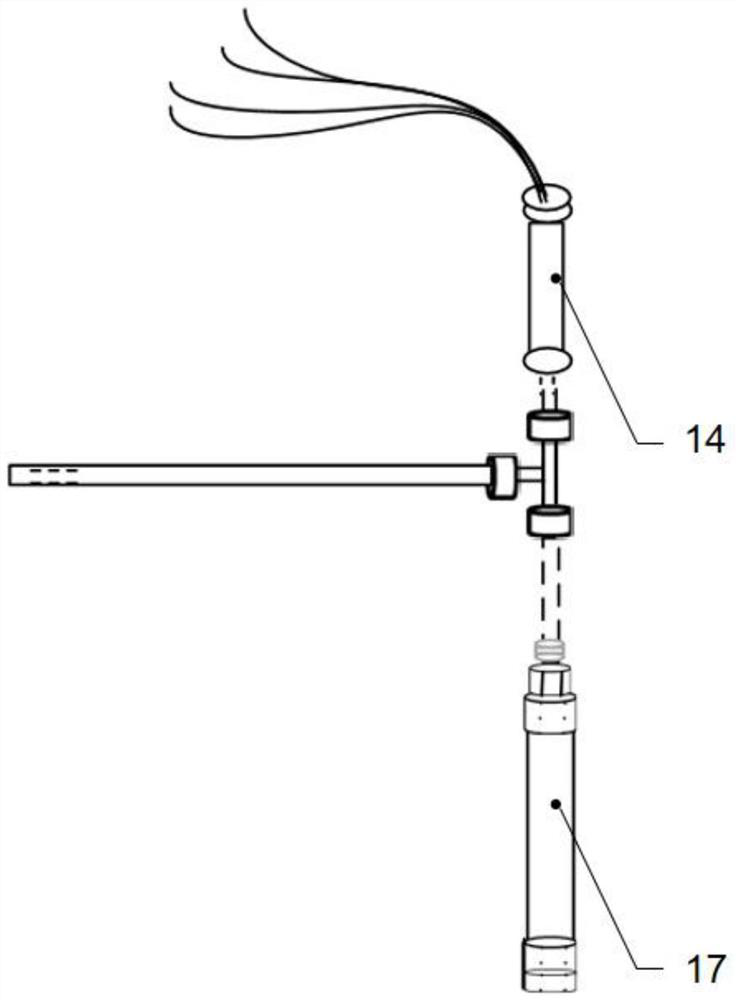

[0049] see figure 1 , the present embodiment provides an unattended vacuum stability test equipment, the test equipment 1 includes: a temperature control box 11, a heating component 12, a thermal insulation cover assembly 13, a gas pressure sensor 14, a test tube sleeve 16, a reaction Test tube 17, temperature sensor 18, housing 110, soaking block 111.

[0050] The casing 110 is installed on the top of the temperature control box 11, and the heating element 12 is arranged inside the casing 110, and the heating element 12 is a resistance wire in this embodiment. The resistance wire is electrically connected with the temperature control box 11, and the temperature control box is used to control the power of the resistance wire. The soaking block 111 provided in the heating component 12 is made of aluminum. At least one accommodating cavity 15 is provided on the soaking block 111 , and in this embodiment, four accommodating cavities 15 are provided on one soaking block 111 , an...

Embodiment 2

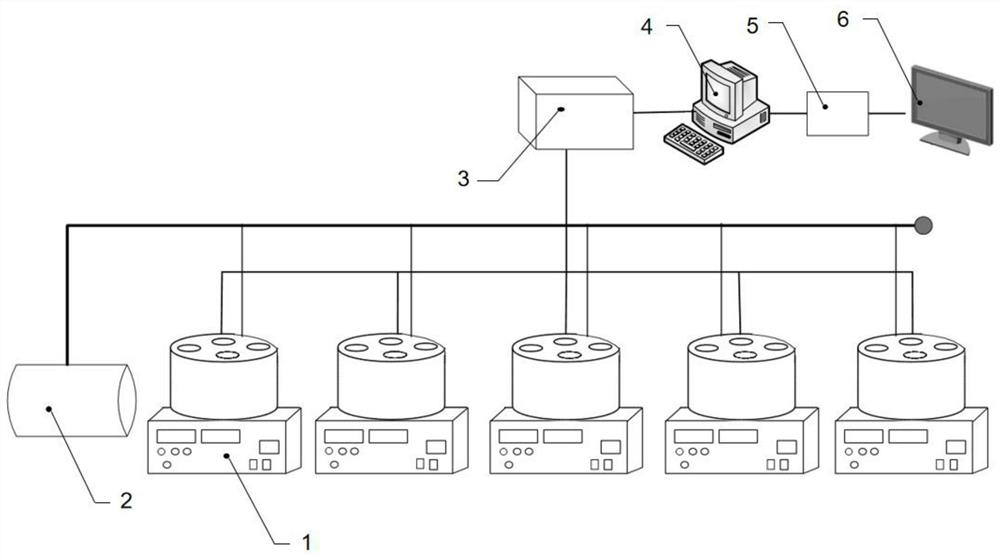

[0054] see image 3 , This embodiment provides an unattended vacuum stability test system, the test system includes: a vacuum pump 2, a tester 3, a host computer 4, and at least one test device 1 as described in Embodiment 1.

[0055] In this embodiment, there are five testing devices 1. The vacuum pump 2 is connected to the three-way pipe fitting through a pipeline, and then vacuumizes the sample in the reaction test tube. The pipeline passes through the insulation cover assembly 13 and enters the accommodating cavity 15 Inside.

[0056] The tester 3 communicates with the gas pressure sensor 14 using a 68-pin dedicated cable, and the temperature sensor 18 communicates through a USB signal line. The upper computer 4 and the tester 3 are connected by a communication line. The upper computer 4 is equipped with testing software and a data analysis module. The tester 3 and the upper computer 4 mainly realize the capture and signal transmission of the reaction test tube air pressu...

Embodiment 3

[0061] This embodiment provides an unattended vacuum stability test method, the test method is based on the test system described in Embodiment 2, the test method includes:

[0062] Step 1: Sample preparation: Place the sample in a vacuum oven for continuous vacuum drying to eliminate the influence of moisture and volatile moisture.

[0063] Step 2: Sample weighing: Weigh the sample according to the experiment, if it is a simple sample, then weigh it directly, if it is a mixed sample, you need to mix the two samples according to a certain ratio.

[0064] Step 3: Sample loading: Place the weighed single sample or mixed sample in the reaction test tube, and then put them together in the reaction sleeve of the test equipment, and assemble the heat preservation cover assembly.

[0065] Step 4: Vacuumize: Vacuumize the reaction test tube containing the sample, and use the test software to automatically detect the airtightness of the internal space of the reactor and the vacuum stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com