A kind of electroplating copper-copper pyrovinate composite interconnect material and silicon substrate and preparation method

A technology for interconnecting materials and silicon substrates, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., and can solve the problems of high electrical conductivity and low thermal expansion coefficient of connecting materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

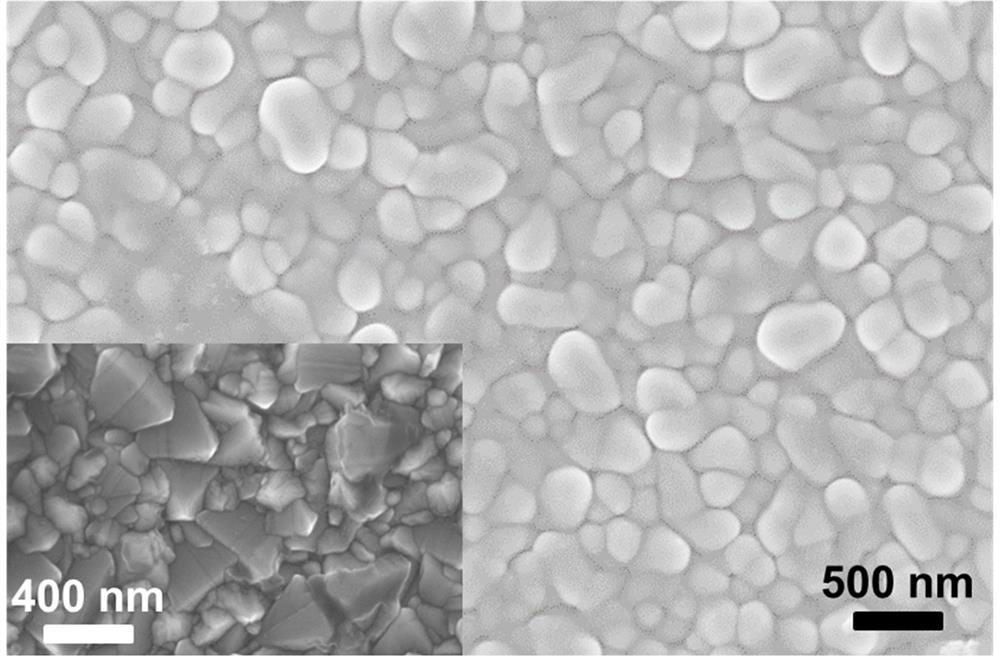

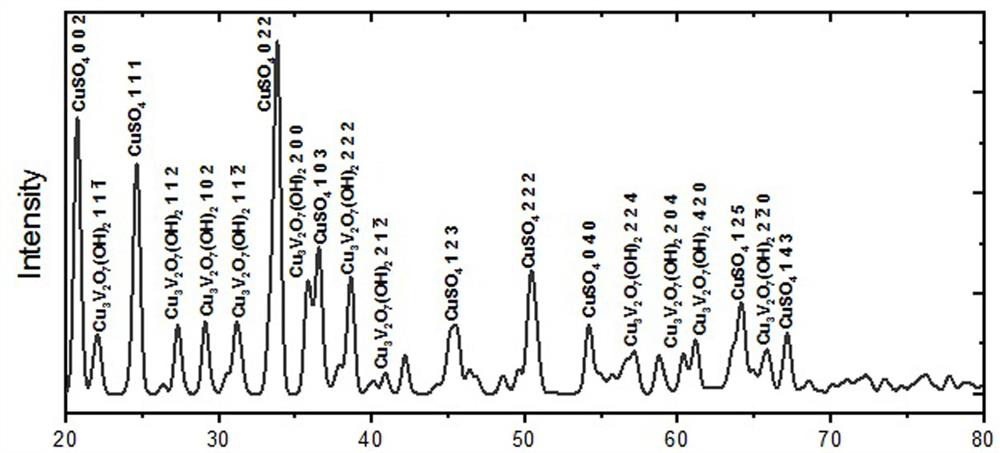

[0051] 0.02mol / L ammonium vanadate solution was titrated into the electroplating solution without electricity, and it was found that with the addition of ammonium vanadate, flocculent precipitates appeared in the electroplating solution. Among them, the formula of electroplating solution is 200g / L Cu 2 SO 4 ·5H 2 O, 55g / L H 2 SO 4 , 100 mg / L CuCl 2 , the plating temperature is 50 °C. Collect and dry the flocs at the bottom of the cup and observe by SEM, the results are as follows figure 1 shown. from figure 1 It can be seen that the precipitates are distributed in granular form, the particle size is about 200 nm, and the size distribution is uniform; from figure 2 It can be seen that the precipitate is mainly Cu as determined by XRD diffraction 3 V 2 O 7 (OH) 2 and CuSO 4 . This shows that the titration of ammonium vanadate in the plating solution can effectively generate β-Cu 2 V 2 O 7 Precursor Cu required 3 V 2 O 7 (OH) 2 particles.

Embodiment 2

[0053] Cu / β-Cu on silicon substrates 2 V2 O 7 Preparation of composite materials:

[0054] Using a current density of 50mA / cm 2 A DC power supply was used to plate Cu on the silicon substrate, and at the same time, the ammonium vanadate solution was titrated into the plating solution, the concentration of the ammonium vanadate solution was 0.02 mol / L, and the titration rate was 1.5 mL / min. Among them, the formula of electroplating solution is 200g / LCu 2 SO 4 ·5H 2 O, 55g / L H 2 SO 4 , 100 mg / L CuCl 2 , the plating temperature is 50 °C.

[0055] After the plating is completed, the samples are heat treated at 600°C and 400°C respectively for 2h. The actual results are shown in the figure. image 3 and Figure 4 Finally, the XRD phase analysis of the composite coating was carried out, and the obtained results were as follows Figure 5 shown.

[0056] from Figure 5 It can be seen that after heat treatment at 400 °C, the Cu 3 V 2 O 7 (OH) 2 Decomposes into β-Cu 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com