Electrolyte with high solvent-sodium salt ratio and sodium ion battery

A sodium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor wettability of pole pieces and separators, affecting high-temperature cycle performance, affecting low-temperature cycle performance, etc. Temperature range, good cycle performance, good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of electrolyte is as follows:

[0056] At room temperature, in a glove box with water content and oxygen content less than 0.1ppm, mix ethylene carbonate (EC) and propylene ester (PC) at a volume ratio of 1:1 to form a solvent, and add it to the solvent according to solvent: sodium salt =20:1 (molar ratio) adding sodium hexafluorophosphate (NaPF 6 ) into a mixed solution, dissolved completely, and left to stand for 24 hours for later use.

[0057] NaCu 1 / 9 Ni 2 / 9 Fe 1 / 3 mn 1 / 3 o 2 As the positive active material, hard carbon is used as the negative active material, glass fiber is used as the diaphragm, and the above electrolyte is used to assemble the CR2032 button battery according to the usual process.

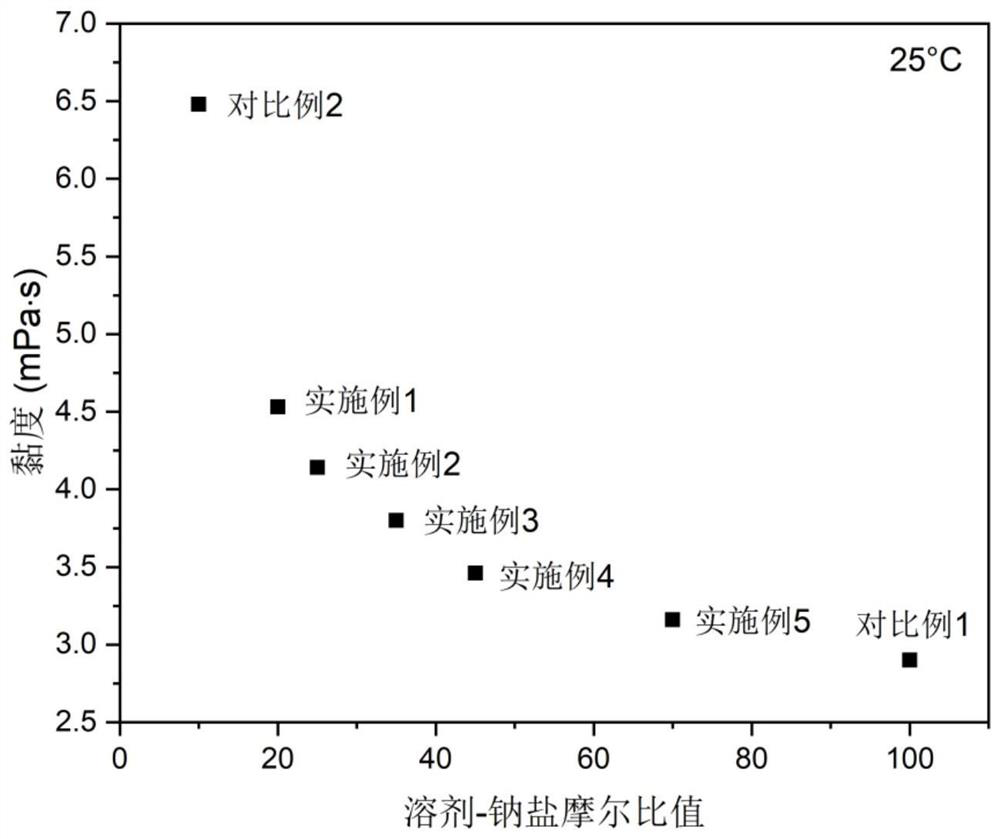

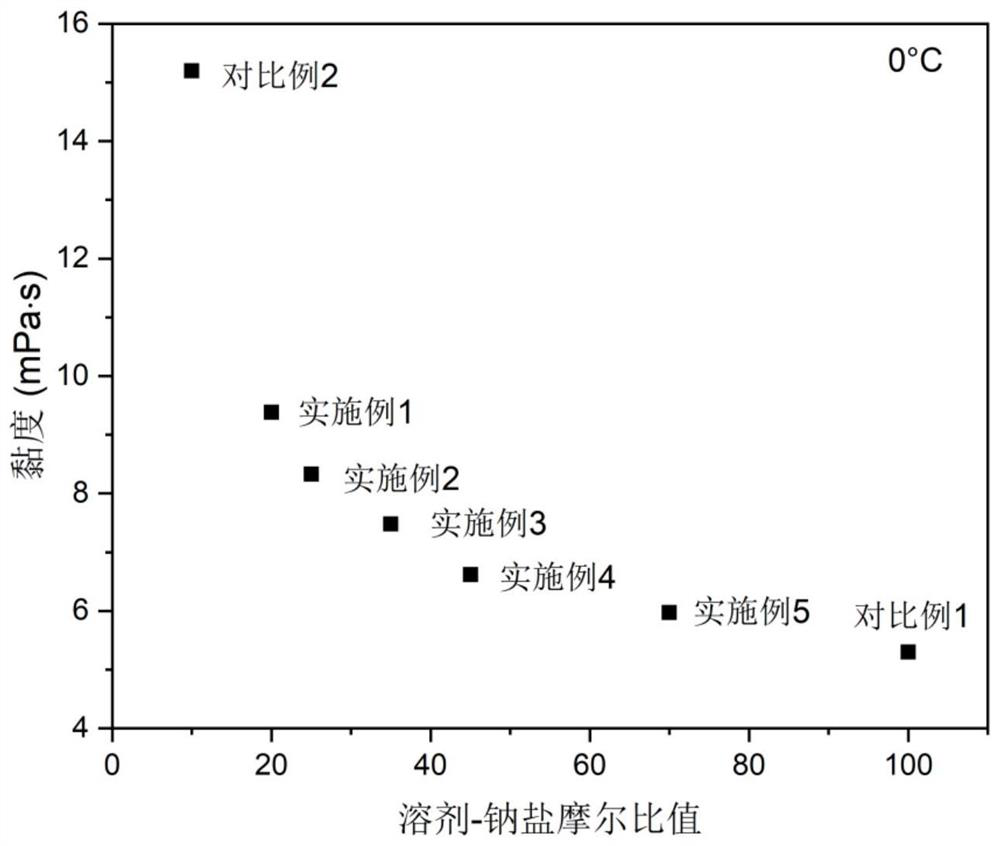

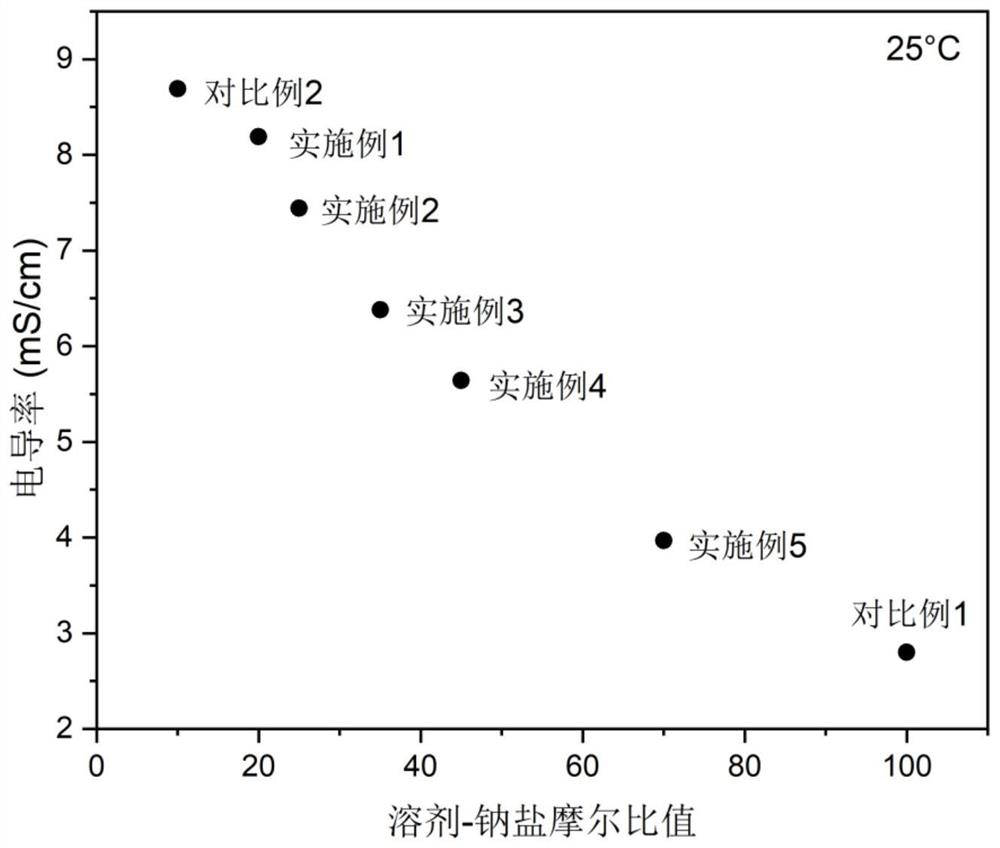

Embodiment 2-26 and comparative example 1-17

[0059] According to the implementation method of Example 1, change the molar ratio of solvent and sodium salt, the type of sodium salt, the type of solvent, the positive electrode active material and the negative electrode active material in Example 1, obtain Example 2-26 and Comparative Example 1-17, electrolysis The composition of the solution and the electrode active materials used are shown in Table 1.

[0060] Table 1: Electrolyte composition and electrode active material selection of Examples 1-26 and Comparative Examples 1-17:

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com