Single-layer or several-single-layer CrTe3 film and preparation method thereof

A thin-film and single-layer technology, applied in the direction of metal selenide/telluride, binary selenium/telluride compounds, etc., can solve the problems of high preparation difficulty and limited purity of bulk materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

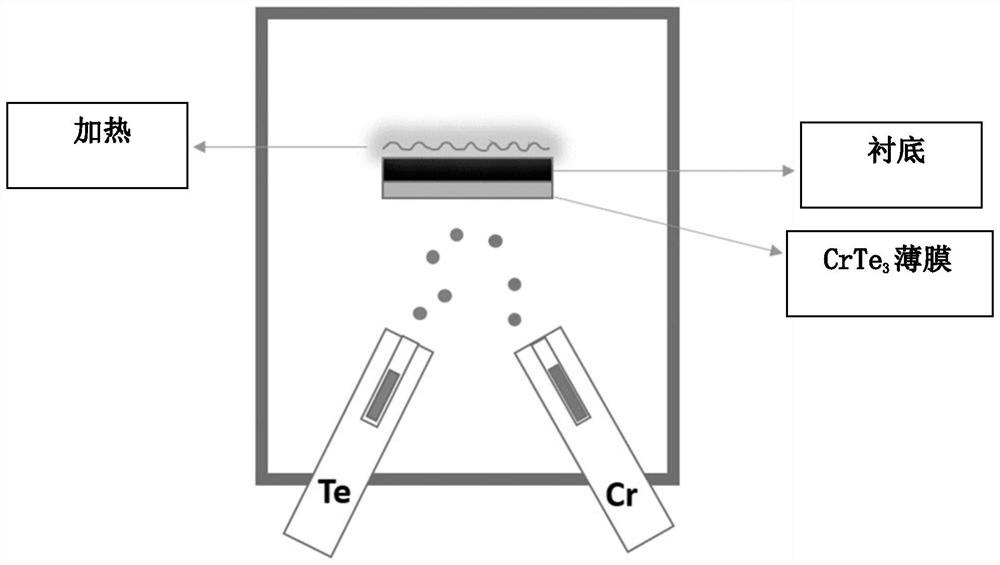

[0056] The specific implementation steps are as follows:

[0057] Step 1: Select high-purity Cr and Te element powders, that is, use Cr with a purity of 99.9999% and Te powder with a purity of 99.9999%, and load them into the K-cell evaporation source respectively.

[0058] Step 2: Insert the Cr and Te sources into the vacuum cavity, and pump the vacuum until the vacuum degree reaches 3.0×10 -6 Pa, in order to increase the vacuum degree, wrap the heating tape on the whole preparation cavity, and bake it to 150°C for 3 days, so that the vacuum on the back can reach 3.0×10 -8 Pa, after the baking is over, degas the Cr and Te sources separately, slowly heat the Te source to 340°C, degas until the Te source is heated to 340°C, and the vacuum degree is less than 1.0×10 -7 Pa. After the end, the Cr source is degassed, and the Cr source is slowly heated to 950°C for degassing. During the process, the vacuum degree of the preparation chamber is kept below 1.0×10 -7 Pa, when the tem...

Embodiment 2

[0065] The specific implementation steps are as follows:

[0066] Step 1: Select high-purity Cr rods and Te element powders, that is, Cr rods with a purity of 99.9999% and Te powders with a purity of 99.9999%, and put them into the electron beam evaporation source and the K-cell evaporation source respectively.

[0067] Step 2: Insert the Cr and Te sources into the vacuum cavity, and pump the vacuum until the vacuum degree reaches 3.0×10 -6 Pa, in order to increase the vacuum degree, wrap the heating tape on the whole preparation cavity, and bake it to 150°C for 3 days, so that the vacuum on the back can reach 3.0×10 -8 Pa, after the baking is over, degas the Cr and Te sources separately, slowly heat the Te source to 340°C, degas until the Te source is heated to 340°C, and the vacuum degree is less than 1.0×10 -7 Pa. After the end, the Cr source is degassed, and the Cr source is slowly heated to 950°C for degassing. During the process, the vacuum degree of the preparation ch...

Embodiment 3

[0074] The specific implementation steps are as follows:

[0075] Step 1: Select high-purity Cr rods and Te element powders, that is, Cr rods with a purity of 99.9999% and Te powders with a purity of 99.9999%, and put them into the electron beam evaporation source and the K-cell evaporation source respectively.

[0076]Step 2: Insert the Cr and Te sources into the vacuum cavity, and pump the vacuum until the vacuum degree reaches 3.0×10 -6 Pa, in order to increase the vacuum degree, the whole preparation cavity can be wrapped with a heating tape, and baked to 150°C for 3 days, so that the vacuum on the back can reach 3.0×10 -8 Pa, after the baking is over, degas the Cr and Te sources separately, slowly heat the Te source to 340°C, degas until the Te source is heated to 340°C, and the vacuum degree is less than 1.0×10 -7 Pa. After the end, the Cr source is degassed, and the Cr source is slowly heated to 950°C for degassing. During the process, the vacuum degree of the prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com