A ZNO-based dilute magnetic semiconductor thin film with intrinsic ferromagnetism and its preparation method

A dilute magnetic semiconductor and ferromagnetic technology, which is applied in the manufacture of semiconductor/solid-state devices, the manufacture/processing of electromagnetic devices, and vacuum evaporation coating, etc. The effect of large area and large-scale production, reducing environmental pollution and reducing growth temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] ZnO films were doped with 3 mol% Er and 2% mol Al (Zn 0.95 Er 0.03 al 0.02 O) as an example:

[0029] (1) Zn was prepared by a standard isostatic solid-state reaction synthesis process 0.95 Er 0.03 al 0.02 O target. Press Zn with electronic balance 0.95 Er 0.03 al 0.02 The stoichiometric ratio of the corresponding elements of O Weigh high-purity (≥99.99%) ZnO (38.6603g), Er 2 o 3 (2.8699g)Al 2 o 3 (0.5098g), after being fully mixed, pre-pressed (50MPa), then cold isostatic pressed (200MPa), and finally placed in a tubular electric furnace and gradually heated to 1000 ° C, and kept for 48 hours.

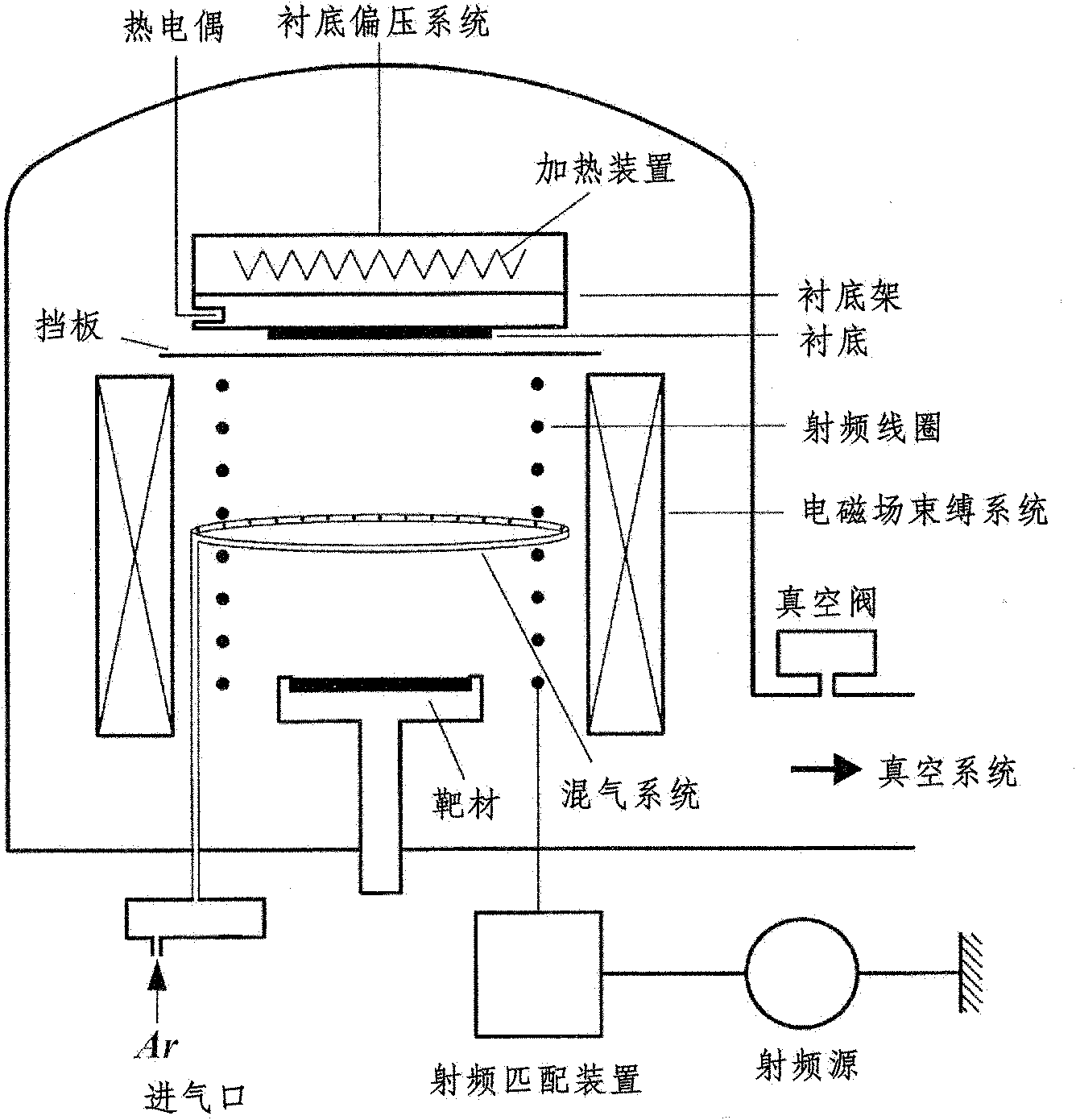

[0030] (2) The quartz glass substrate is cleaned with N 2 Blow dry and place in the reaction chamber of an inductively coupled plasma-enhanced physical vapor deposition device.

[0031] (3) Pump the background vacuum of the inductively coupled plasma enhanced physical vapor deposition device system to ≤5×10 -5 Pa, heat the substrate to 300°C, then pump the vacuum...

Embodiment 2

[0041] ZnO films were doped with 2% mol Er and 1% mol Al (Zn 0.97 Er 0.02 al 0.01 O) as an example:

[0042] (1) Zn was prepared by a standard isostatic solid-state reaction synthesis process 0.97 Er 0.02 al 0.01 O target. Press Zn with electronic balance 0.97 Er 0.02 al 0.01 The stoichiometric ratio of the corresponding elements of O weighs high-purity (≥99.99%) ZnO (39.4742g), Er 2 o 3 (1.9126g), Al 2 o 3 (0.2549g), after being fully mixed, pre-pressed (50MPa), then cold isostatic pressed (200MPa), and finally placed in a tubular electric furnace and gradually heated to 1100 ° C, and kept for 48 hours.

[0043] (2) Clean the Si substrate with N 2 Blow dry and place in the reaction chamber of an inductively coupled plasma-enhanced physical vapor deposition device. The inductively coupled plasma enhanced physical vapor deposition device system, i.e. ICP-PVD system, such as figure 1 shown.

[0044] (3) Pump the background vacuum of the inductively coupled plasma...

Embodiment 3

[0050] ZnO films were doped with 1% mol Er and 1% mol Al (Zn 0.98 Er 0.01 al 0.01 O) as an example:

[0051] (1) Zn was prepared by a standard isostatic solid-state reaction synthesis process 0.98 Er 0.01 al 0.01 O target. Press Zn with electronic balance 0.98 Er 0.01 al 0.01 The stoichiometric ratio of the corresponding elements of O weighs high-purity (≥99.99%) ZnO (39.8811g), Er 2 o 3 (0.9563g), Al 2 o 3 (0.2549g), after being fully mixed, pre-pressed (50MPa), then cold isostatic pressed (200MPa), and finally placed in a tubular electric furnace and gradually heated to 1200 ° C, and kept for 48 hours.

[0052] (2) Clean the SiC substrate, dry it with N2 and put it into the reaction chamber of the inductively coupled plasma enhanced physical vapor deposition device. The inductively coupled plasma enhanced physical vapor deposition device system, i.e. ICP-PVD system, such as figure 1 shown.

[0053] (3) Inductively coupled plasma enhanced physical vapor deposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Electron concentration | aaaaa | aaaaa |

| Average surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com