Method for preparing zinc oxide base magnetic semiconductor material using sub-nanometer composite method

A magnetic semiconductor, sub-nanometer technology, applied in the fields of semiconductor/solid-state device manufacturing, inorganic material magnetism, electrical components, etc., can solve the problems of material performance uncertainty, difficult control of metal ions, etc., and achieve stable performance and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

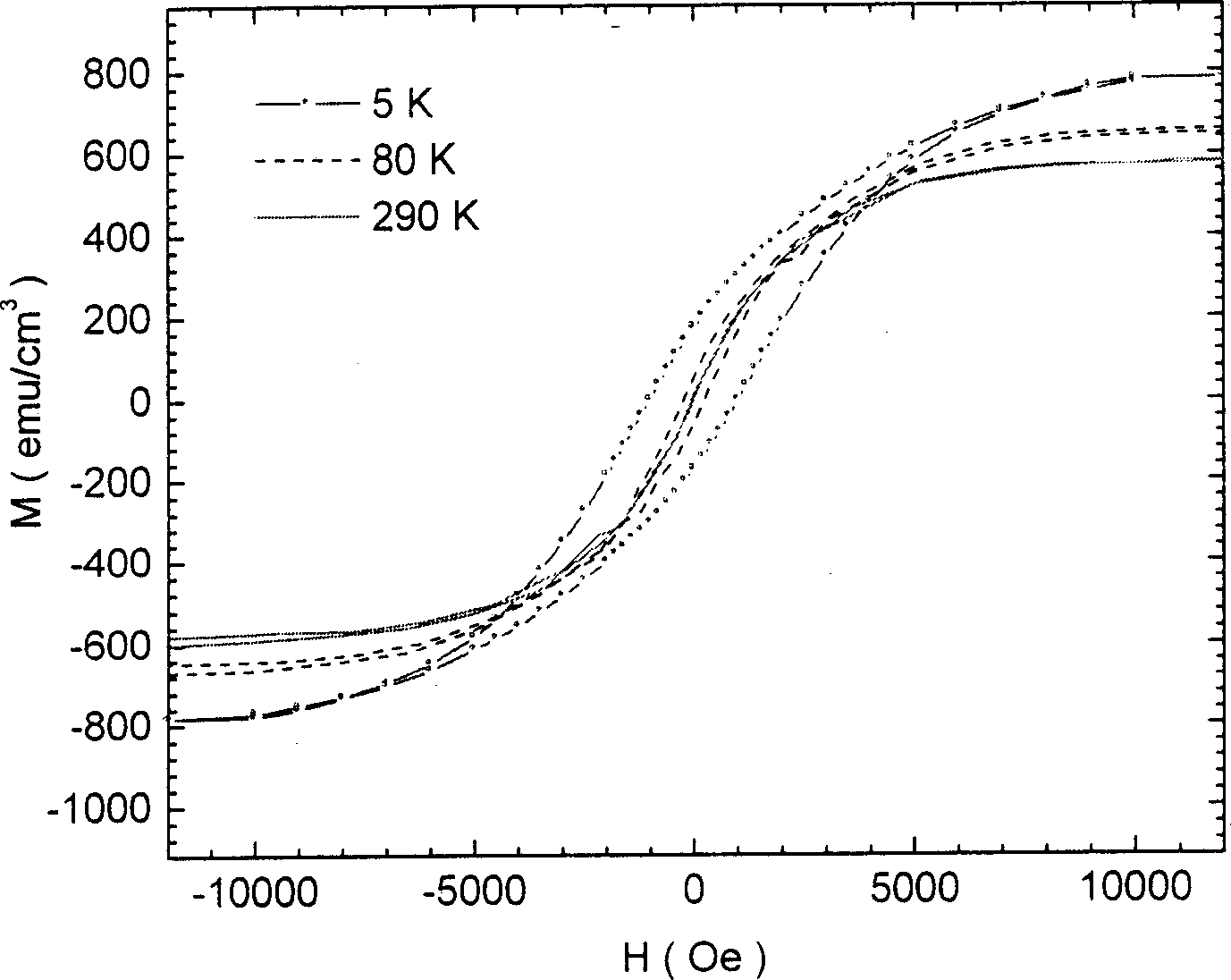

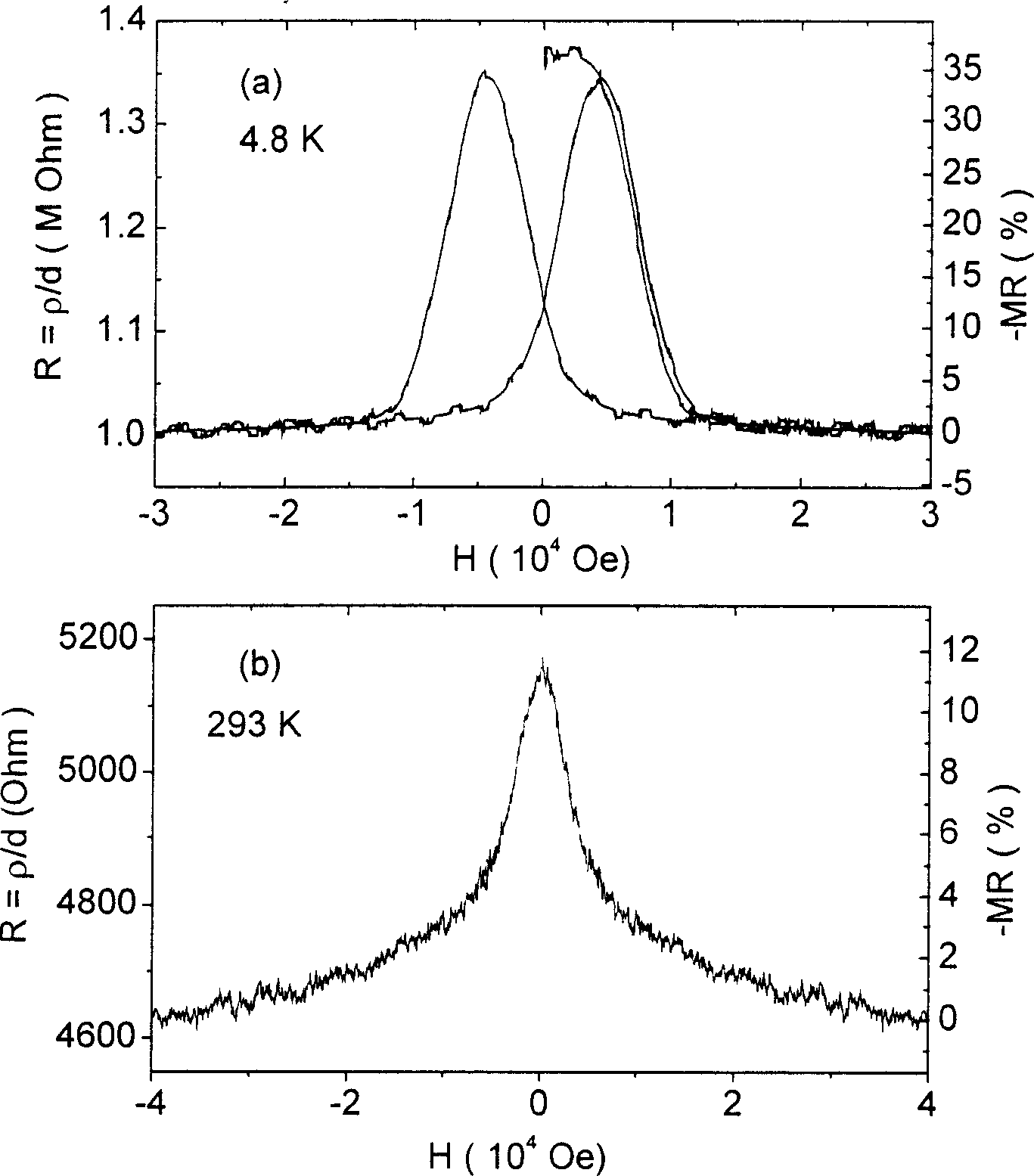

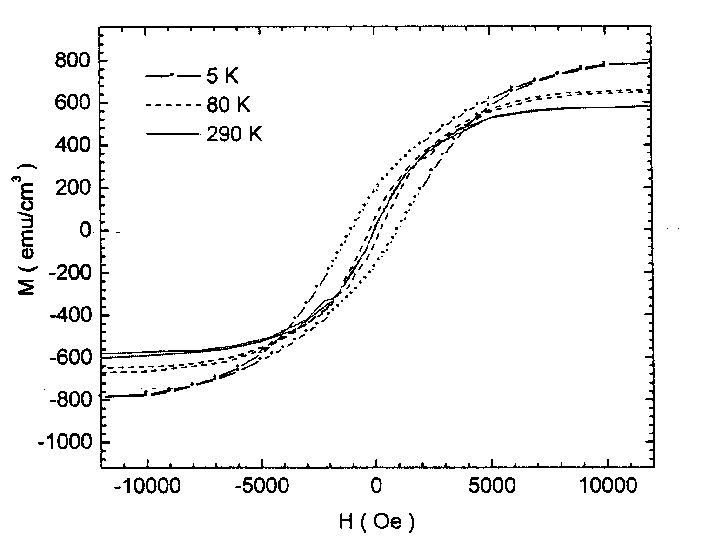

[0020] A Co-doped ZnO magnetic semiconductor (1#) was prepared by alternately growing Co and ZnO thin films on a room temperature quartz glass substrate by magnetron sputtering. The Co layer was prepared by DC sputtering with a growth rate of 0.05nm / s. The thickness is 0.6nm; ZnO is prepared by radio frequency sputtering, the growth rate is 0.02nm / s, and the thickness is 0.5nm. Grow for 60 cycles.

Embodiment 2

[0022] Using molecular beam epitaxy and laser molecular beam epitaxy to alternately grow Fe and ZnO thin films on room temperature single crystal silicon substrates, a Fe-doped ZnO magnetic semiconductor (2#) was prepared. The Fe layer was prepared by molecular beam epitaxy, and the growth rate was 0.01nm / s, thickness 0.1nm; ZnO is prepared by laser molecular beam epitaxy, growth rate is 0.005nm / s, thickness 0.3nm. Grow for 120 cycles.

Embodiment 3

[0024] The FeNi-doped ZnO magnetic semiconductor (3#) was prepared by alternately growing FeNi and ZnO thin films on a common glass substrate at room temperature by magnetron sputtering. The FeNi layer was prepared by DC sputtering with a growth rate of 0.04nm / s and a thickness of 0.2nm; ZnO is prepared by radio frequency sputtering with a growth rate of 0.02nm / s and a thickness of 0.8nm. 80 cycles of growth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com