Preparation method of high-whiteness and high-toughness epoxy resin composite material

A tough epoxy resin and composite material technology, applied in the field of polymer composite materials, can solve the problems of cumbersome process, no mass production, and environmental pollution, and achieve the effect of simple process and no organic solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

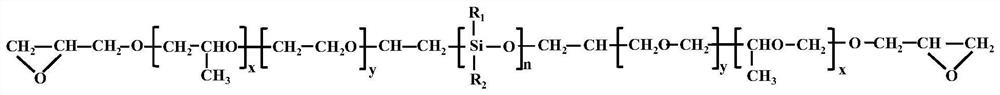

Method used

Image

Examples

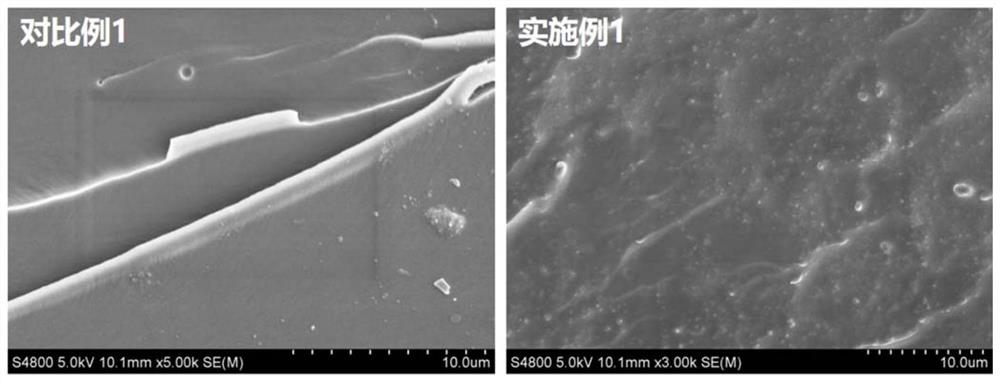

Embodiment 1

[0024] Add 10 parts by mass of epoxy-terminated polyether polysiloxane (polydimethylsiloxane segment: 3000 g / mol, epoxy polyether segment: 500 g / mol) with a molecular weight of 4000 g / mol into 100 After stirring at high speed for 30 minutes in parts by mass of bisphenol A epoxy resin (bisphenol A glycidyl ether), add 25 parts by mass of curing agent polyetheramine D230, and continue stirring at high speed for 10 minutes. Put the mixture into an oven, vacuumize for 10 minutes, remove the air bubbles introduced by stirring, and then pour it into a mold for curing reaction. The curing conditions are: curing for 1 hour at 25° C., and curing at 60° C. for 4 hours to prepare an epoxy resin composite material.

Embodiment 2

[0028] Add 20 mass parts of epoxy-terminated polyether polysiloxane (polydimethylsiloxane segment: 4000g / mol, epoxy polyether segment: 500g / mol) with a molecular weight of 5000g / mol to 100 In the bisphenol A epoxy resin (bisphenol A glycidyl ether) of mass parts, after stirring at high speed for 30 minutes, add the curing agent methyl hexahydrophthalic anhydride of 85 mass parts and 1.5 mass parts of 2,4,6 - Tris(dimethylaminomethyl)phenol, continue stirring at high speed for 10 minutes. Put the mixture into an oven, vacuumize for 10 minutes, remove the air bubbles introduced by stirring, and then pour it into a mold for curing reaction. The curing conditions are: curing at 110° C. for 1.5 hours, then raising the temperature to 160° C. and curing for 4 hours to prepare an epoxy resin composite material.

Embodiment 3

[0032] Add 25 mass parts of epoxy-terminated polyether polysiloxane (polydimethylsiloxane segment: 7700g / mol, epoxy polyether segment: 500g / mol) with a molecular weight of 8700g / mol to 100 In the bisphenol A epoxy resin (bisphenol A glycidyl ether) of mass parts, after stirring at high speed for 30 minutes, add 24.5 mass parts of curing agent diethyltoluenediamine, and continue stirring at high speed for 10 minutes. Put the mixture into an oven, vacuumize for 10 minutes, remove the air bubbles introduced by stirring, and then pour it into a mold for curing reaction. The curing conditions are: curing at 110° C. for 1 hour, then raising the temperature to 180° C. and curing for 2 hours, and an epoxy resin composite material is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com