A preparation device for semi-insulating indium phosphide

A preparation device and a technology for indium phosphide, which are applied in chemical instruments and methods, polycrystalline material growth, single crystal growth and other directions, can solve the problems of few indium phosphide annealing techniques and inapplicability to indium phosphide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

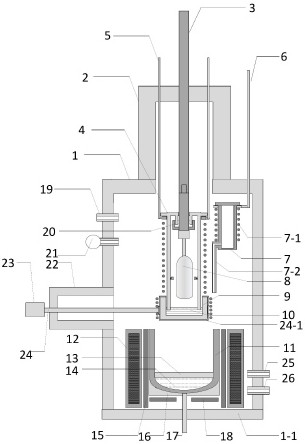

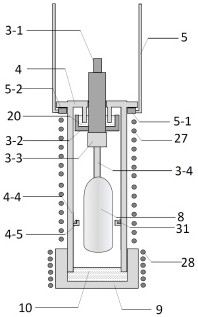

[0031] see figure 1 , a preparation device for semi-insulating indium phosphide, comprising a furnace body, a crucible 11, a heating and supporting system, a seed rod 3 passing through the furnace body, a hydrogen pipe 25 and an inert gas pipe 26 arranged on the side of the furnace body , Exhaust pipe 19; An injector 7 is provided in the furnace body, and the injection lifting rod 6 connected to the injector 7 protrudes out of the furnace body to connect the driving device (marked in the figure); an in-situ annealing device is also arranged in the furnace body.

[0032] The heating and supporting system of the crucible 11 includes a thermal insulation cover 12 , a main heater 15 , a graphite support 16 , a crucible rod 17 , and a lower heater 18 .

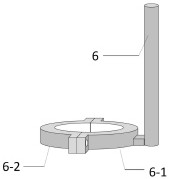

[0033] see figure 2 , the lifting rod 6 is connected to the injector 7 through the right support 6-1 of the injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com