Zero-carbon-emission LNG fuel power ship cold energy waste heat comprehensive gradient utilization system

A cascade and cold energy technology, applied in pipeline systems, ship components, ship construction, etc., can solve the problems of waste of low-temperature waste heat resources, thermal pollution, etc., and achieve the effects of energy saving, emission reduction, carbon emission reduction, and improvement of energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

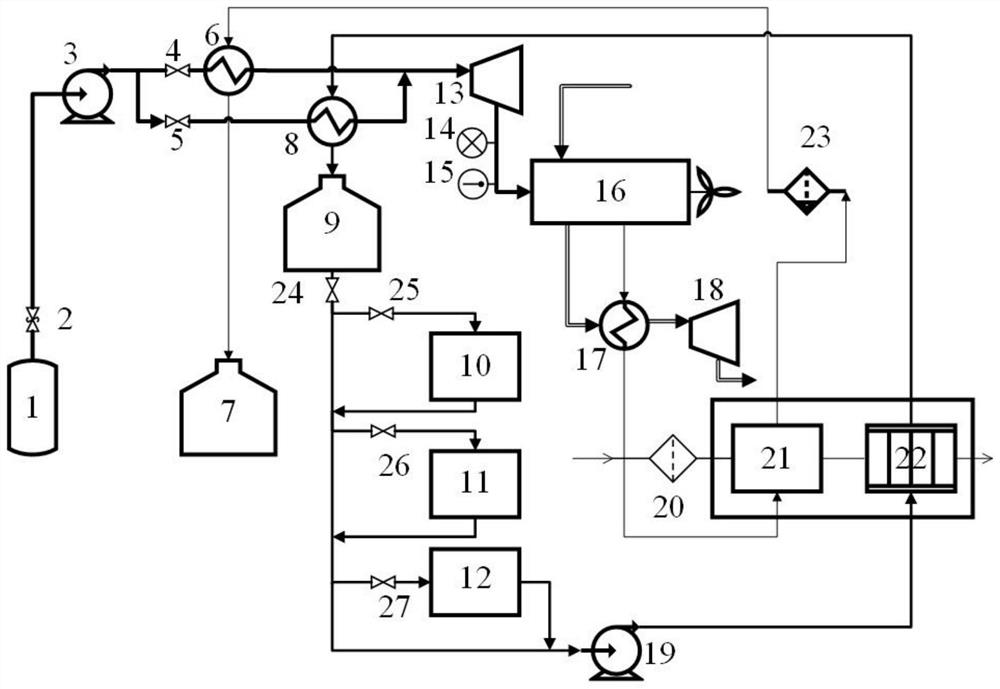

[0031] As shown in the figure, the present invention provides a comprehensive cascade utilization system of cold energy and waste heat of LNG fuel-powered ships with zero carbon emissions, including the cascade utilization subsystem of LNG cold energy, the cascade utilization subsystem of tail gas waste heat, and the CO 2 Liquefaction capture subsystem. Among them, the LNG cold energy cascade utilization subsystem is mainly composed of LNG storage tank 1, transfer pump 1, heat exchanger 1 6, heat exchanger 2 8, natural gas turbine 13, ship main engine 16, brine storage tank 9, and transfer pump 2.19. The seawater desalination condenser 22 and several valves and pipelines and other components; the tail gas waste heat cascade utilization subsystem is mainly composed of ship main engine 16, heat exchanger 3 17, steam turbine 18, seawater desalination evaporator 21 and pipelines and other components Composition; CO 2 The liquefaction capture subsystem is mainly composed of tail g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com