Production technology of net-shaped filter material for waste gas filtration

A technology of production process and production process flow, which is applied in the field of production process of mesh filter material used for exhaust gas filtration, and can solve the problem that mesh structure filter profiles cannot be satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

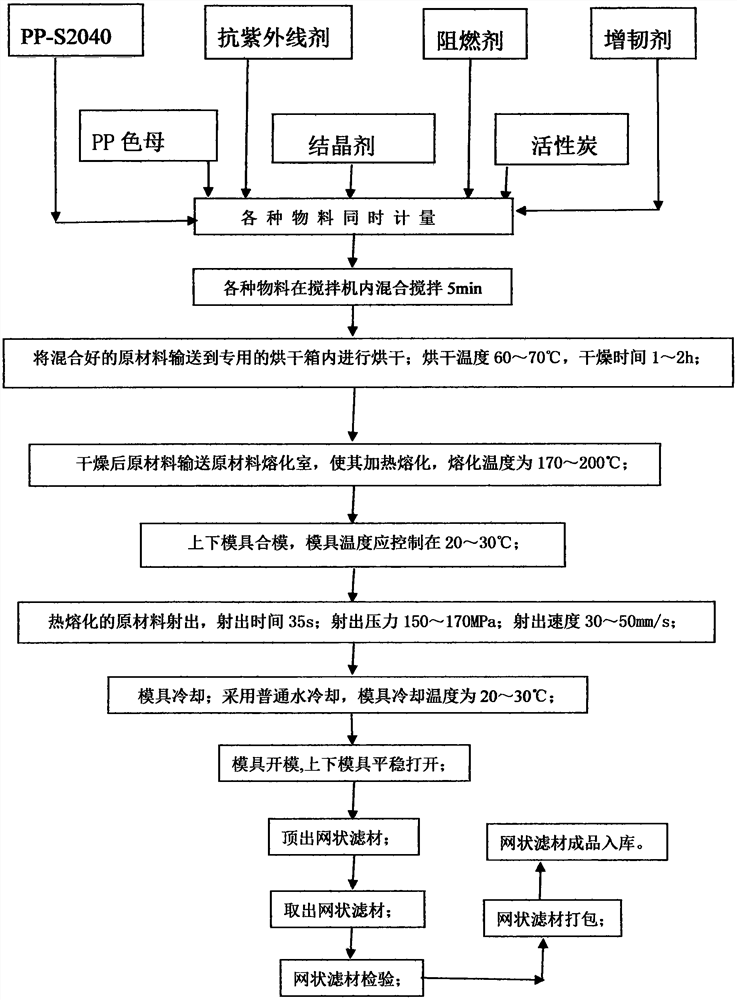

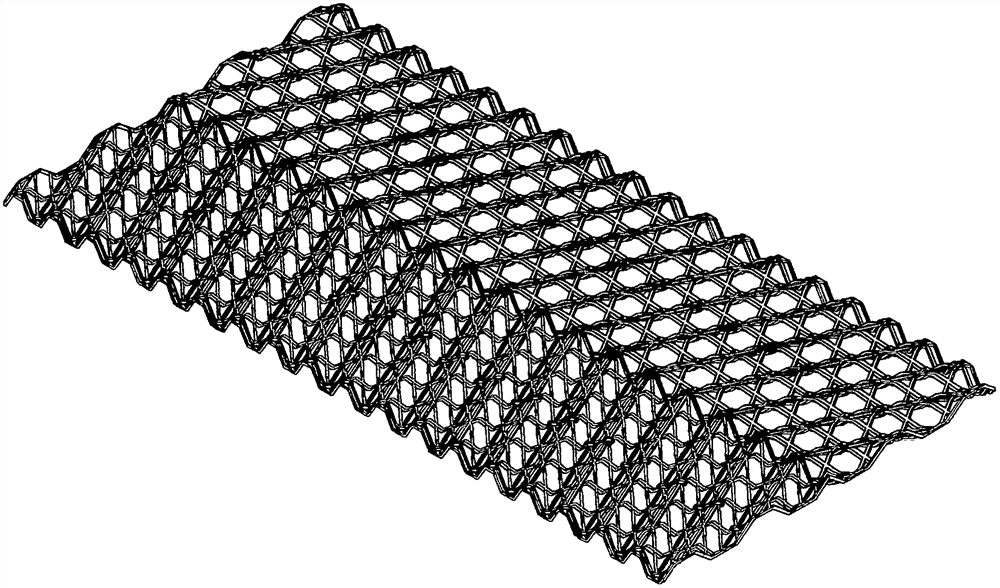

[0020] The present invention is realized in this way, the following is combined with the appendix Figure 1 to Figure 2 To further illustrate: a production process for a mesh filter material for waste gas filtration, characterized in that: it includes materials, proportions and production process flow, and the proportions of materials are: PP-S2040 67-81.5%, anti-ultraviolet agent 3 ~6%, flame retardant 10~15%, toughening agent 1~3%, PP color masterbatch 3~5%, crystallization agent 1~3%, activated carbon 1~3%; the production process is as follows:

[0021] 1) Put PP-S2040, anti-ultraviolet agent, flame retardant, toughening agent, PP color masterbatch, crystallization agent, activated carbon and other materials into their respective silos;

[0022] 2) Simultaneously measure PP-S2040, anti-ultraviolet agent, flame retardant, toughening agent, PP color masterbatch, crystallization agent, activated carbon, etc. according to the ratio;

[0023] 3) These metered materials are sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com