Anti-crack concrete and preparation method thereof

A concrete and mixture technology, applied in the field of concrete, can solve the problems of concrete performance reduction, concrete toughness deterioration, spalling, etc., and achieve the effects of improving compactness, tight bonding, and improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

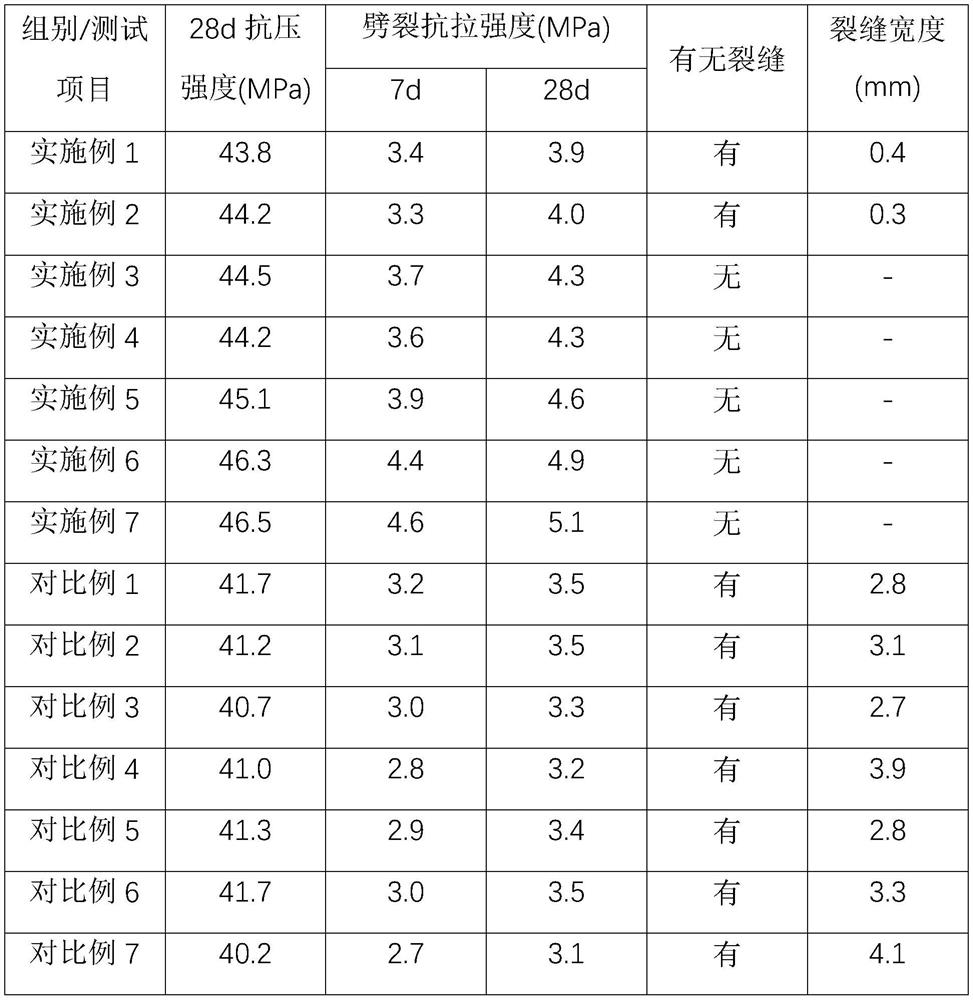

Examples

Embodiment 1-3

[0053] A method of preparing concrete cracking, comprising the steps of:

[0054] Step 1) polycarboxylate superplasticizer, zinc acetate, sodium metabisulfite and water into the stirred tank, stirred at temperature 60 ℃ and speed 60r / min for 6 minutes, the mixture was stirred to give a first, standby.

[0055] Step 2) cement, slag, fly ash, gravel, river sand into the horizontal mixer, stirred at speed 80r / min full 2 minutes to prepare a second mixture is stirred;

[0056] Step 3) The first mixture was stirred and polyvinyl alcohol fibers were added to a second stirred mixture was stirred at sufficient speed 90r / min for 1 minute, and then put into a dry ice for 1 minute, to prepare concrete cracking.

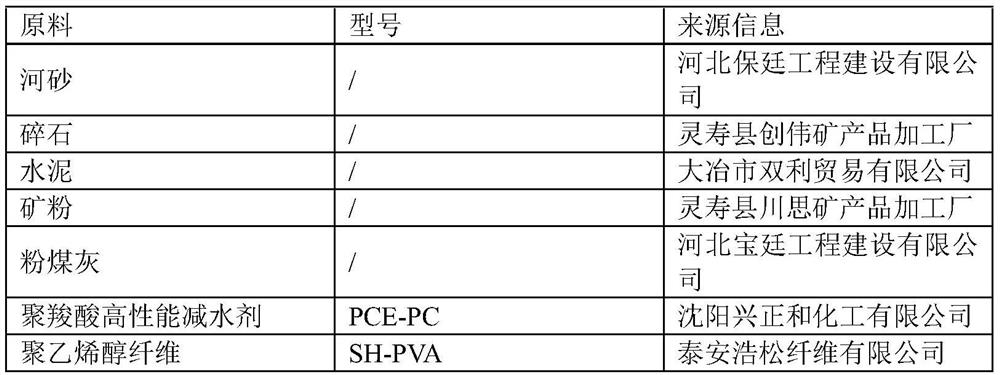

[0057] Referring to the various inputs of the raw materials in Table 2, wherein the slag is slag ground ore crushed to powder with a particle size range of 0.15-0.3mm; dry ice particle size in the range of 2.5-10mm, polyvinyl alcohol fibers length ranging from 3-10 mm, fine ...

Embodiment 4

[0061] A method of preparing a crack-cracking concrete, and 0.07 kg of six methyltrine is also invested in step 3).

Embodiment 5

[0063] A method of preparing a crack-cracking concrete, and 0.032 kg of tetraborate is also invested in step 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com