Anti-corrosion waterproof cement-based grouting material and preparation method thereof

A cement-based and grouting material technology, applied in the field of building materials, can solve the problem of difficulty in guaranteeing the thickness of the dense protective layer, and achieve the effects of improving the compaction performance and waterproof and impermeability, promoting development and application, and reducing the overall cost of construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

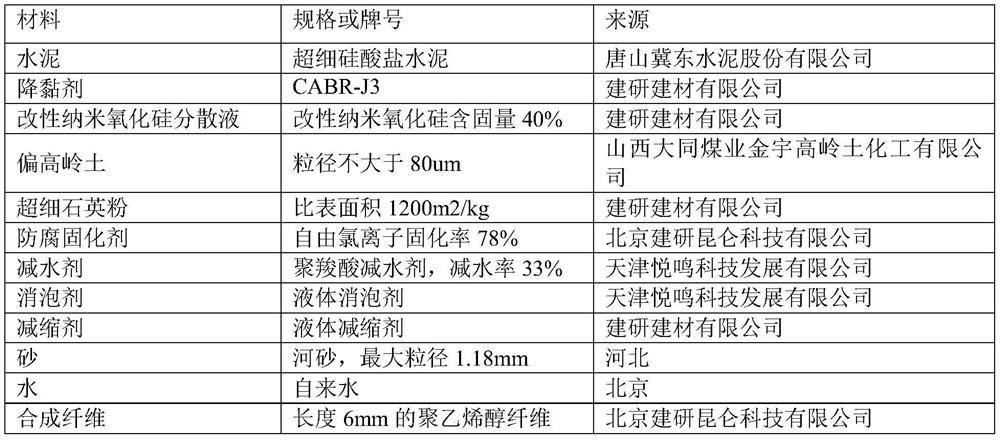

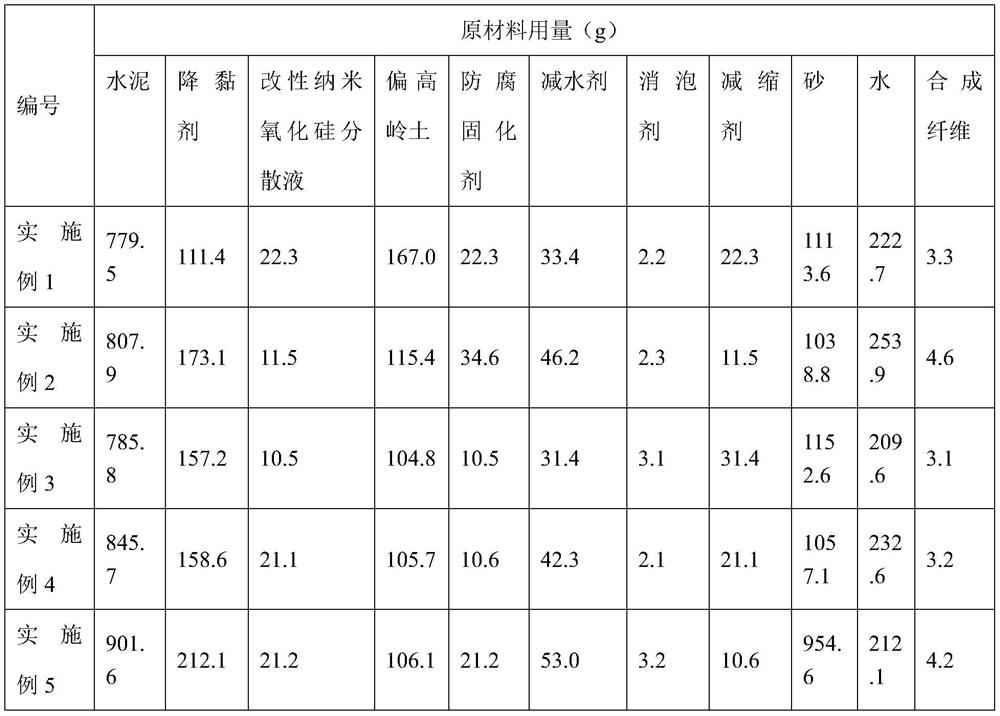

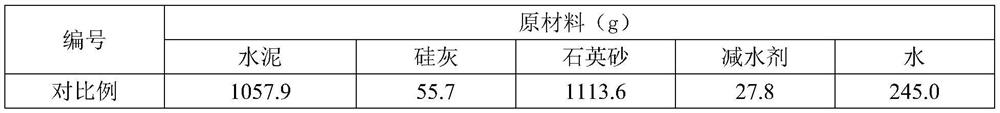

[0039] The preparation method of the anti-corrosion and waterproof cement-based grouting material of Examples 1-5 comprises the following steps:

[0040] S1. Add sand, cement, viscosity reducer, metakaolin, ultrafine quartz powder, anti-corrosion curing agent, synthetic fiber, and stir for 1-2 minutes;

[0041]S2. Add water-soluble defoamer and water reducer to the product obtained in step S1, stir for 3 to 5 minutes, and mix thoroughly to form a cement-based grout mixture. By controlling the water reducer and water consumption, Keep the fluidity within the range of 320±30mm;

[0042] S3. Add the modified nano-silica dispersion and the shrinkage reducing agent to the cement-based grout mixture obtained in step S2, and stir for 2 to 3 minutes to obtain the mixture;

[0043] S4. Molding the mixture obtained in step S3, and curing it at room temperature for 1 to 7 days in an environment with a relative humidity ≥ 95%;

[0044] S5. After the finished product is removed from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com