Transient, bearing and stealth integrated composite material as well as preparation method and application thereof

A composite material and transient technology, applied in the direction of heat exchange materials, chemical instruments and methods, camouflage paint, etc., can solve the problems that drone materials cannot achieve transient disappearance, do not have stealth functions, etc., and achieve simple structure, Easy to form, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also proposes a method for preparing a composite material integrating transient state, bearing capacity and stealth, comprising the following steps:

[0052] S1: Select a phase change matrix, heat and melt the phase change matrix to obtain a melt; the phase change matrix undergoes a phase change under a thermal trigger condition;

[0053] S2: adding a reinforcement phase to the melt, mixing uniformly to obtain a mixture; the reinforcement phase includes a mechanical reinforcement phase, a thermal conductivity enhancement phase, a photothermal enhancement phase and a wave absorption enhancement phase;

[0054] The four reinforcement phases of mechanical enhancement phase, heat conduction enhancement phase, photothermal enhancement phase and wave absorption enhancement phase can be the same material or multiple materials.

[0055] S3: Pour the mixture into a mold, press molding, and cool to room temperature to obtain a molding material;

[0056] S4:...

Embodiment 1

[0066] This embodiment provides a composite material that integrates transient state, load bearing and stealth. The composite material is a thermally triggered solid-liquid phase change composite material, including a phase change matrix and a reinforcing phase. The phase change matrix and the The reinforcing phase is compounded together through interfacial interaction;

[0067] The phase change matrix is paraffin and ethylene-vinyl acetate, and a phase change occurs under thermal trigger conditions;

[0068] The reinforcing phase is carbon black and graphene, and both carbon black and graphene are mechanically reinforcing phases, thermal conductivity enhancing phases, photothermal enhancing phases and wave-absorbing enhancing phases, and the mass ratio of the reinforcing phases to the phase change matrix is 0.4:1 ;

[0069] The surface of the composite material is coated with a coating, and in this embodiment, the coating is a polyurethane paint;

[0070] This embodimen...

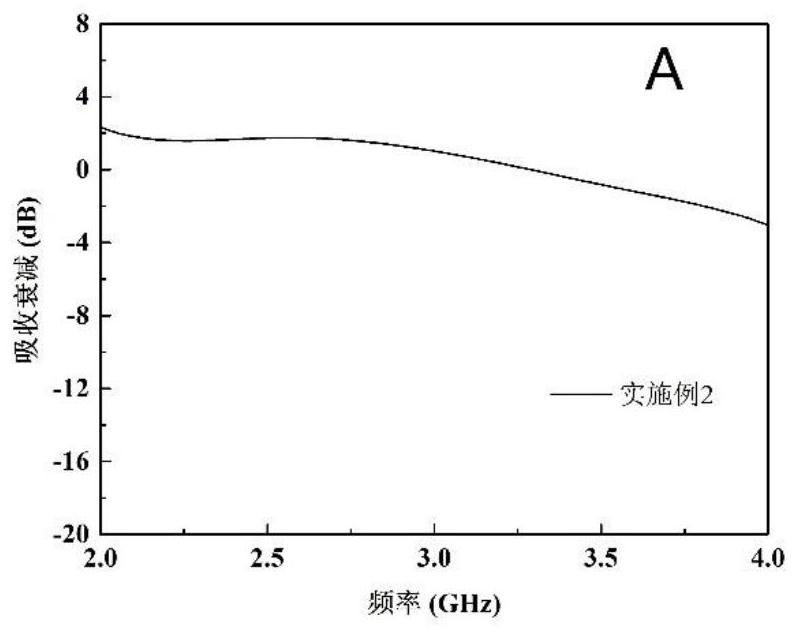

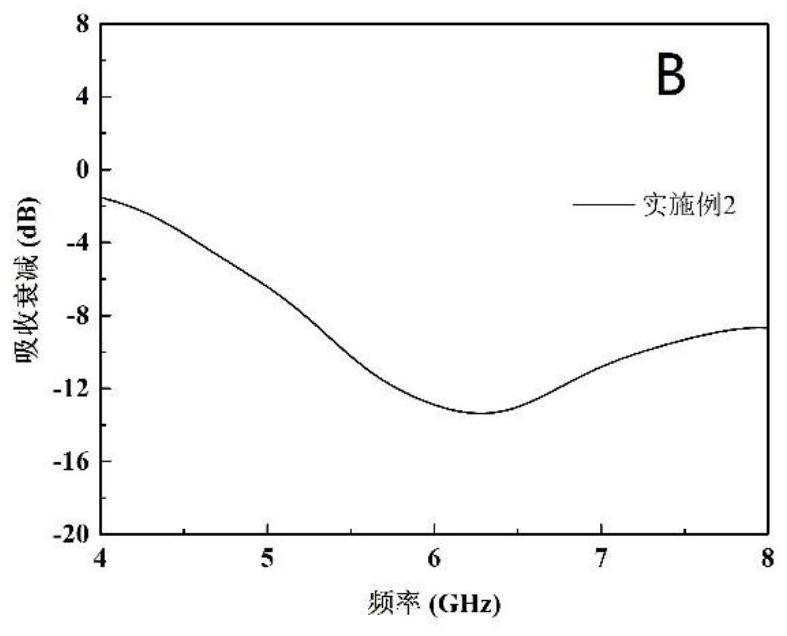

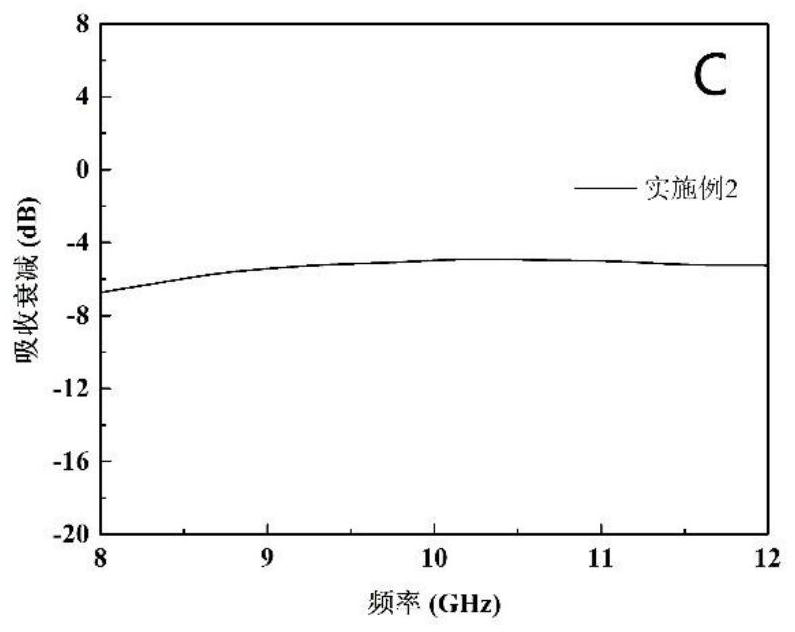

Embodiment 2

[0077] This embodiment provides a composite material that integrates transient state, load bearing and stealth. The composite material is a thermally triggered solid-liquid phase change composite material, including a phase change matrix and a reinforcing phase. The phase change matrix and the The reinforcing phase is compounded together through interfacial interaction;

[0078] The phase change matrix is paraffin and polycaprolactone, which undergoes a phase change under thermal trigger conditions;

[0079] The reinforcement phase is carbon black and silicon carbide fiber, and both carbon black and silicon carbide fiber are mechanical reinforcement phase, thermal conductivity enhancement phase, photothermal enhancement phase and wave absorption enhancement phase, and the mass ratio of reinforcement phase to phase change matrix is 0.75 :1;

[0080] The surface of the composite material is coated with a coating, which is an acrylic paint in this embodiment;

[0081] This ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com