Ultraviolet ray-curable silicone adhesive agent composition, and method for producing laminate

A technology of adhesive layer and ultraviolet rays, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of reduced resin strength, lack of adhesion to substrates, and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

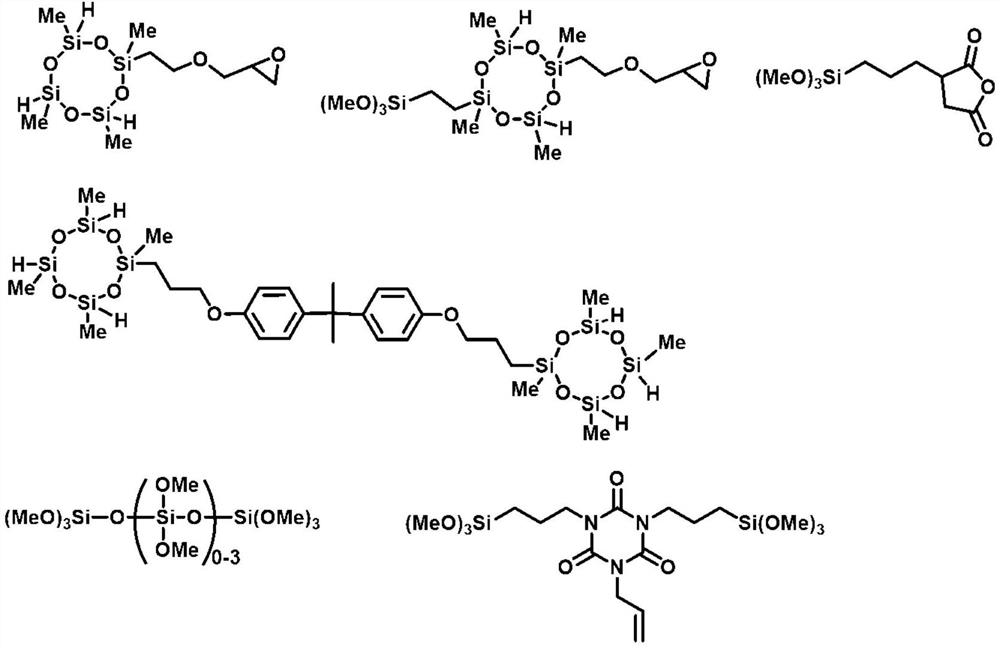

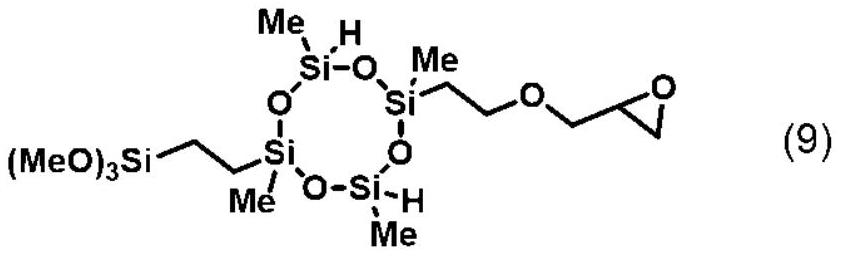

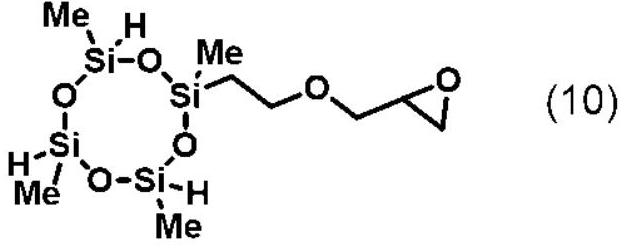

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~4

[0163] The above components were mixed in the compounding quantities (parts by mass) shown in Table 1 to prepare a silicone adhesive composition.

[0164] [Table 1]

[0165]

[0166] The following tests were implemented for each silicone adhesive composition prepared in each of the above-mentioned Examples and Comparative Examples. These results are shown in Table 2.

[0167] (1) Hardness

[0168] Each silicone adhesive composition prepared in the above-mentioned examples and comparative examples was cast into a glass dish, using a UV-LED lamp with a peak wavelength of 365nm, using 365nm light as an indicator, at 23°C with an irradiation intensity of 100mW / cm 2 and a dose of 1500mJ / cm 2 Each composition was irradiated with ultraviolet rays in a manner. After completion of the irradiation, the composition was left to stand at 23° C. in an air atmosphere for 24 hours to cure the composition.

[0169] About each cured product obtained, the hardness was measured using th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com