Preparation method of low-calorie water-soluble dietary fiber resistant dextrin

A technology of resistant dextrin and dietary fiber, which is applied in the field of resistant dextrin, can solve the problems that the time cannot be adjusted freely, the reaction process is not easy to control, and the reaction yield is low, so as to achieve sufficient reaction time for dextrinization and avoid starch Agglomeration, the effect of increasing the specific surface area of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment provides a low-calorie soluble dietary fiber resistant dextrin embodiment the present preparation method, comprising the steps of:

[0042] (1) corn starch weighing 1kg, starch uniformly sprayed to 500mL aqueous solution containing 1.5g of hydrochloric acid, and stirred to obtain a uniform wet starch;

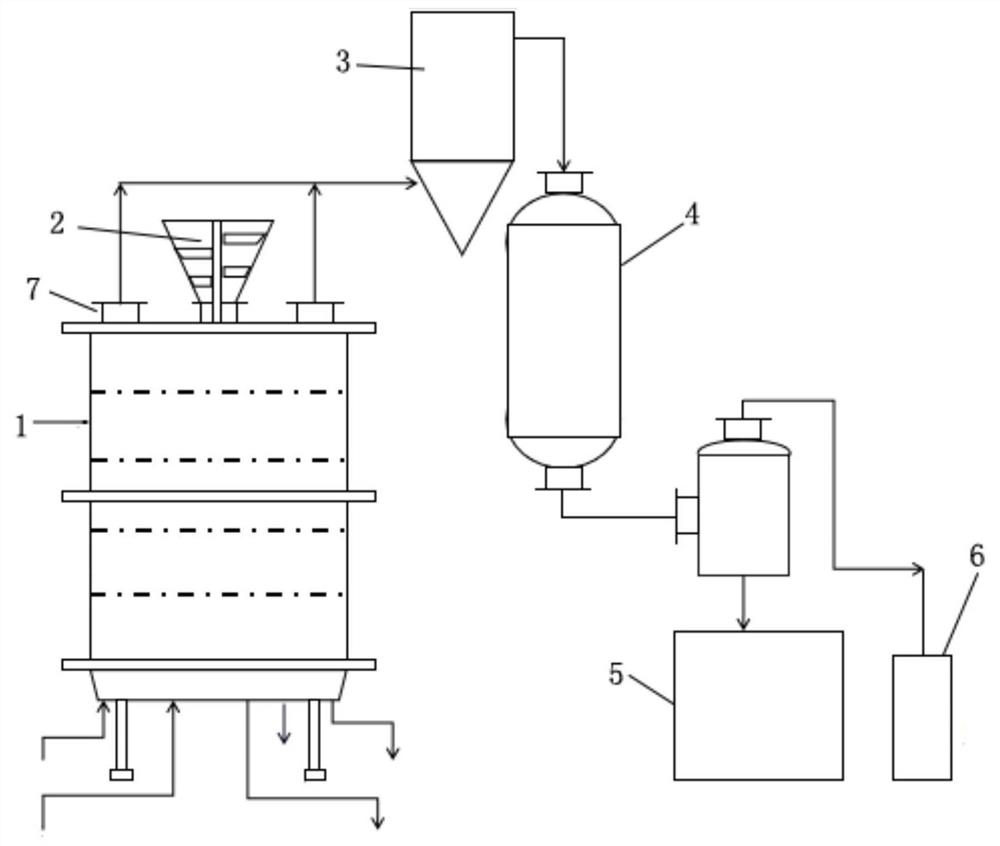

[0043] (2) figure 1 Tray dryer shown in FIG 1 to 5 disk layers dried, the inner temperature was raised to 170. disk HTF deg.] C, the top of the wet starch apparatus fed from feeder 2, the feeding amount is set to 8Hz, spindle speed 3 revolutions / minute, open the fan, the material to be discharged after the reaction product scorching Jingcu continuously through a tray dryer; acid vapors escaping during the reaction gas outlet means is discharged from a top outlet 7, after the dust has 3, a condenser 4 into the recovery reservoir tank 5;

[0044](3) dissolved in water Jingcu burnt product, dubbed a concentration of 30% (by scorching Jingcu product) solutions, ...

Embodiment 2

[0046] The embodiment provides a low-calorie soluble dietary fiber resistant dextrin embodiment the present preparation method, comprising the steps of:

[0047] (1) corn starch weighing 1kg, starch uniformly sprayed to 500mL aqueous solution containing 1.5g of sulfuric acid and stirred uniformly to obtain a wet starch;

[0048] (2) figure 1 Tray dryer shown in FIG 1 to 5 disk layers dried, the inner temperature was raised to 160. disk HTF deg.] C, the top of the wet starch apparatus fed from feeder 2, the feeding amount is set to 12Hz, spindle speed of 5 revolutions / minute, open the fan, the material to be discharged after the reaction product scorching Jingcu continuously through a tray dryer; acid vapors escaping during the reaction gas outlet means is discharged from a top outlet 7, after the dust has 3, a condenser 4 into the recovery reservoir tank 5;

[0049] (3) dissolved in water Jingcu burnt product, dubbed concentration of 40% (by scorching Jingcu product) solutions, ...

Embodiment 3

[0051] The embodiment provides a low-calorie soluble dietary fiber resistant dextrin embodiment the present preparation method, comprising the steps of:

[0052] (1) potato starch was weighed 1kg, starch uniformly sprayed to 500mL aqueous solution containing 1.5g of nitric acid, with stirring to give a uniform wet starch;

[0053] (2) figure 1 1 shown in a tray dryer set to a drying tray layer 4, the inner temperature was raised to HTF plate 180 ℃, the top of the wet starch apparatus fed from feeder 2, the feeding amount is set to 10Hz, spindle speed 2 revolutions / minute, open the fan, the material to be discharged after the reaction product scorching Jingcu continuously through a tray dryer; acid vapors escaping during the reaction gas outlet means is discharged from a top outlet 7, after the dust has 3, a condenser 4 into the recovery reservoir tank 5;

[0054] (3) dissolved in water Jingcu burnt product, dubbed a concentration of 30% (by scorching Jingcu product) solutions, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com