Preparation method of composite edible film

A technology of food and protein powder, applied in the direction of climate sustainability, sustainable manufacturing/processing, flexible coverings, etc., can solve the problems of insufficient mechanical properties, poor resistance, poor water resistance, etc., and achieve enhanced application value , extend the storage period, improve the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Pour 6g of cornstarch into 100mL of distilled water, and magnetically stir in a water bath at 90°C to make the cornstarch completely gelatinized for 30 minutes, then add 2g of glycerin, stir well and set aside; then extract the rock peas at a concentration of 2g / 100mL The protein powder was added to ultrapure water preheated at 40°C, the pH of the solution was adjusted to 8.0 with 1mol / L NaOH, and then magnetically stirred in a water bath at 75°C for 30 minutes before use. Finally, the prepared two solutions are mixed evenly according to the ratio of corn starch: rock bean protein powder mass ratio of 3:1, and then add 0.5g / kg limonene-hydrogenated rosin glyceride particles, after stirring evenly, pour it by casting method On a 40*40cm acrylic plate, dry at 65°C for 3 hours, take it out, put the film in a constant temperature and humidity box with a temperature of 20°C and a humidity of 50% for 24 hours, and finally peel off the film, the yield is 90%. The obtained edib...

Embodiment 2

[0029] The tensile strength of the edible films prepared in each group of examples and comparative examples was tested, and the specific implementation method was as follows: a texture analyzer was used to evaluate the mechanical properties of the films. The films were cut into uniform 60 mm x 10 mm samples and tested at a tensile speed of 50.00 mm / min to determine their tensile strength, elongation at break.

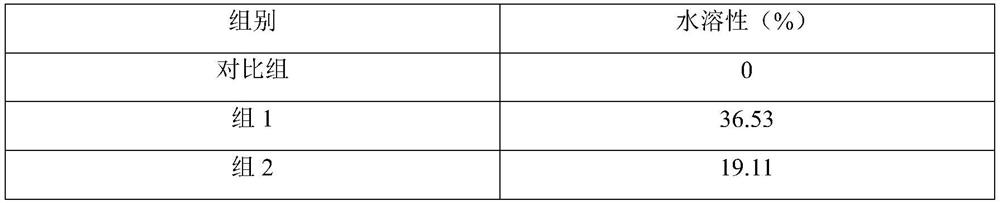

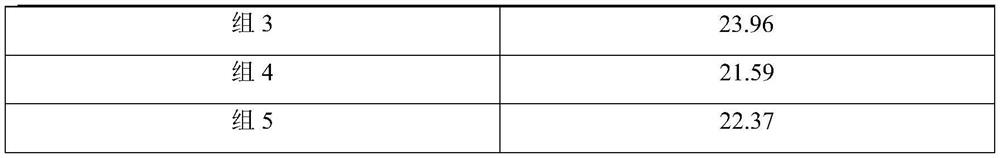

[0030] Experiments were carried out with 6 groups of different plastic wraps, each group was carried out 3 times, and the average value was taken:

[0031] Contrast group: commercially available PE plastic wrap.

[0032] Group 1, yellow pea protein / corn starch film: dissolve corn starch, add glycerin and magnetically stir, then add fully dissolved yellow pea protein powder (mass ratio of corn starch: yellow pea protein powder is 3:1), adjust the pH , adding limonene-hydrogenated rosin glyceride particles, and then casting into a film after stirring evenly.

[0033] Gr...

Embodiment 3

[0042] Taking mochi as the fresh-keeping object, the fresh-keeping properties of five kinds of edible films were tested. The wrapped mochi were placed in PP fresh-keeping boxes without sealing. The growth of colonies on the surface of mochi was observed and photographed every other day. Group test material is the same as embodiment 1, contrast group is commercially available PE cling film, and test result is as shown in table 2.

[0043] Group / Days first day third day fifth day seventh day comparison group sterile Obvious bacteria Obvious bacteria Obvious bacteria group 1 sterile sterile A small amount of bacteria Obvious bacteria group 2 sterile A small amount of bacteria Obvious bacteria Obvious bacteria group 3 sterile sterile sterile A small amount of bacteria group 4 sterile A small amount of bacteria Obvious bacteria Obvious bacteria Group 5 sterile sterile sterile A small amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com