Foamed silica gel special for simulation robot and preparation method of foamed silica gel

A technology for simulating robots and foamed silica gel, applied in the field of foamed silica gel, can solve the problems of low relative density and uneven cell size, and achieve the effect of increasing the foaming ratio, avoiding uneven size and uniform cell size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

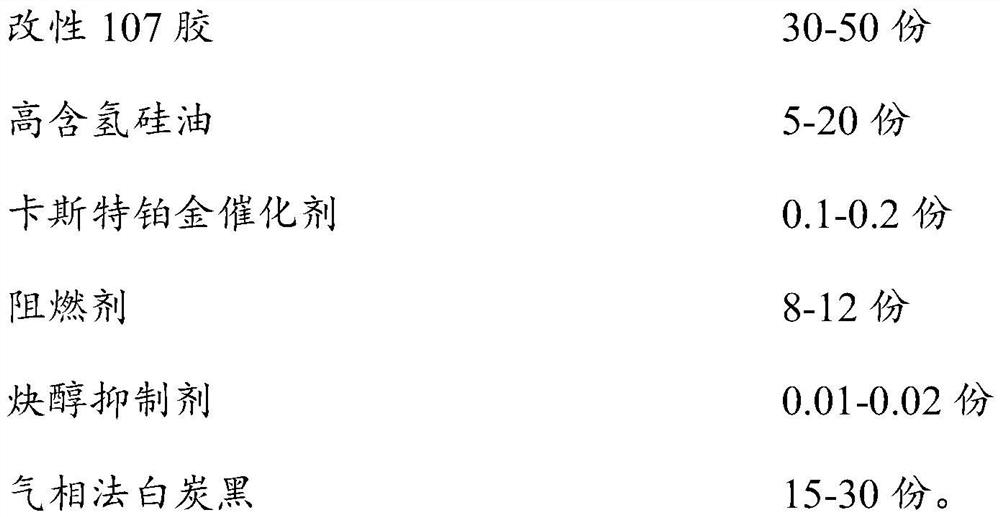

Embodiment 1

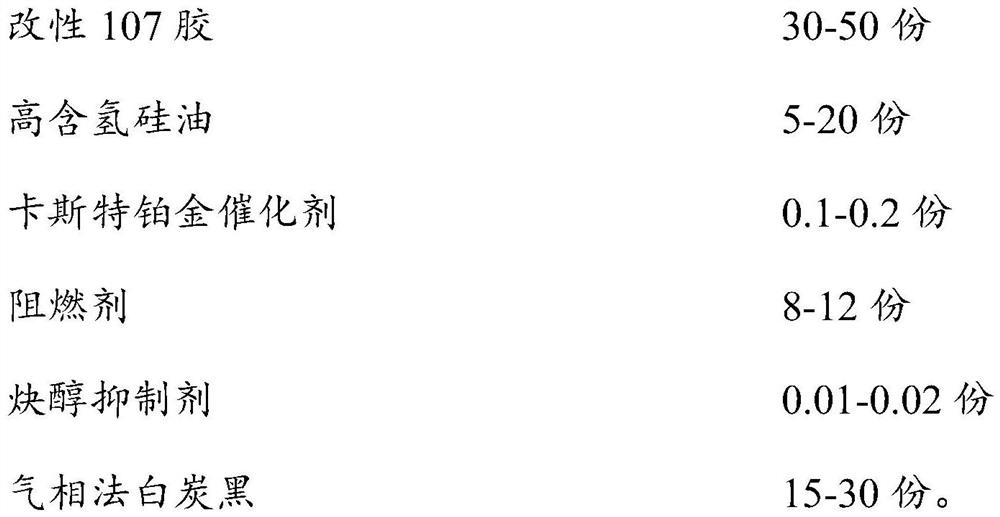

[0028] 30 parts of modified 107 glue, 20 parts of fumed white carbon black, 0.01 part of acetylenic alcohol inhibitor, 5 parts of high hydrogen-containing silicone oil, 0.1 part of castor catalyst, and 10 parts of flame retardant.

[0029] Wherein, the high hydrogen-containing silicone oil is used as the crosslinking agent reacted in this embodiment, and its structural formula is

[0030]

[0031] Wherein, n is a hydrogen-containing methyl chain, m is a polymethyl chain, and the ratio of n / m is greater than 0.5.

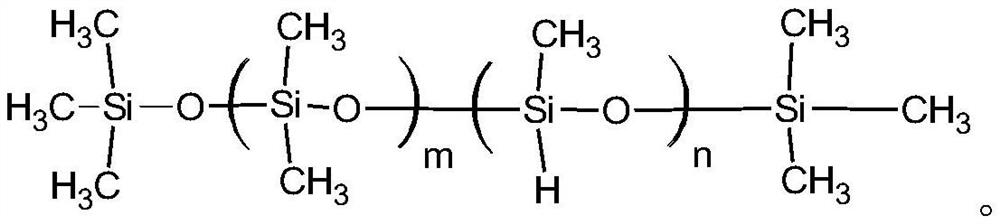

[0032] Among them, the modified 107 glue is prepared by the reaction of hydroxyl-terminated vinyl-containing silicone oil and hydroxyl hydrogen-containing silicone oil under the catalysis of Castel platinum catalyst. The reaction principle is as follows,

[0033]

[0034] Among them, both ends and side chains of the modified 107 glue contain hydroxyl groups, and the total content of hydroxyl groups is greater than 2%.

[0035] Among them, the flame retardant i...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is:

[0045] 30 parts of modified 107 glue, 15 parts of fumed white carbon black, 0.02 parts of acetylenic alcohol inhibitor, 10 parts of high hydrogen-containing silicone oil, 0.1 part of castor catalyst, and 8 parts of flame retardant.

[0046]In this example, the preparation method is as follows: in step (1), after adding the Castel platinum catalyst, react at 105°C for 5 hours, then adjust the temperature to 140°C, and control the vacuum degree to -0.01MPa to prepare modified 107 Glue; the kneading time in the kneader is 5 hours, then raise the temperature to 115°C and knead for 2 hours, then raise the temperature to 175°C to remove low boilers, the ratio of component A to component B in step (3) is 8:1 .

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is:

[0049] 40 parts of modified 107 glue, 15 parts of fumed white carbon black, 0.02 parts of acetylenic alcohol inhibitor, 10 parts of high hydrogen-containing silicone oil, 0.1 part of castor catalyst, and 12 parts of flame retardant.

[0050] In this example, the preparation method is as follows: in step (1), after adding Castel platinum catalyst, react at 115°C for 6 hours, then adjust the temperature to 160°C, and control the vacuum degree to -0.03MPa to prepare modified 107 Glue; the kneading time in the kneader is 6 hours, then raise the temperature to 125°C and knead for 3 hours, then raise the temperature to 185°C to remove low boilers, the ratio of component A to component B in step (3) is 12:1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com