Activation method of Fischer-Tropsch synthesis iron-based catalyst and activation system of Fischer-Tropsch synthesis catalyst

A technology of iron-based catalysts and activation methods, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as aggravating catalyst fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

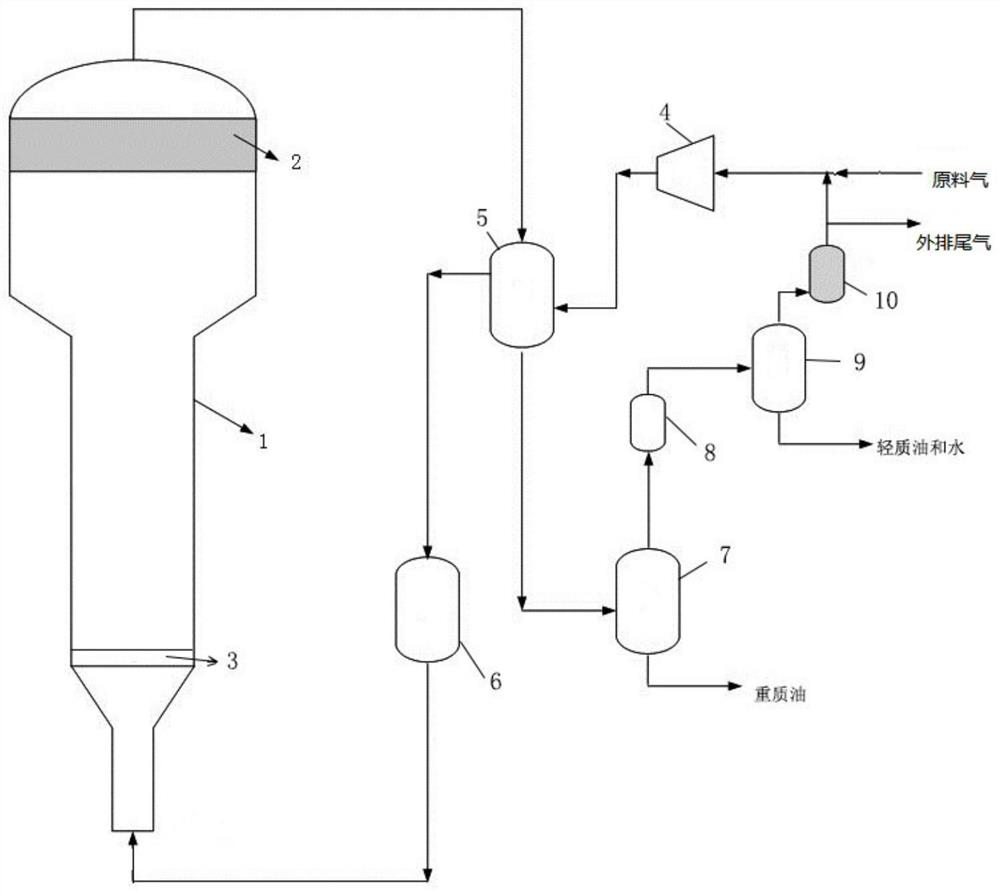

[0071] Such as figure 1 In the flow process shown, the activation reactor 1 (being a gas-solid fluidized bed reactor) has an internal diameter of 0.12 m and a height of 16 m. The bottom of the activation reactor 1 is provided with a gas distributor 3 with a pore size of 0.2 mm, and the top is provided with a gas distributor with a blowback system. Metal sintered wire mesh filter, and supporting cyclone separator (that is, a gas-solid separator 2). The outlet of the activation reactor 1 is connected to the gas circulation heat exchanger 5, and through the heavy oil separator 7, heavy oil is produced at the bottom of the heavy oil separator 7, and the product at the top outlet passes through the heat exchanger 8 for heat exchange and cooling, Enter the light oil-water separator 9, the bottom of the light oil-water separator 9 produces light oil and water, the gas at the top outlet enters the oil wash separator 10, and a small part of the gas from the oil wash separator 10 is dis...

Embodiment 2

[0089] The activation process is the same as in Example 1, except that different temperature curves are used in the operating process in the activation reactor 1.

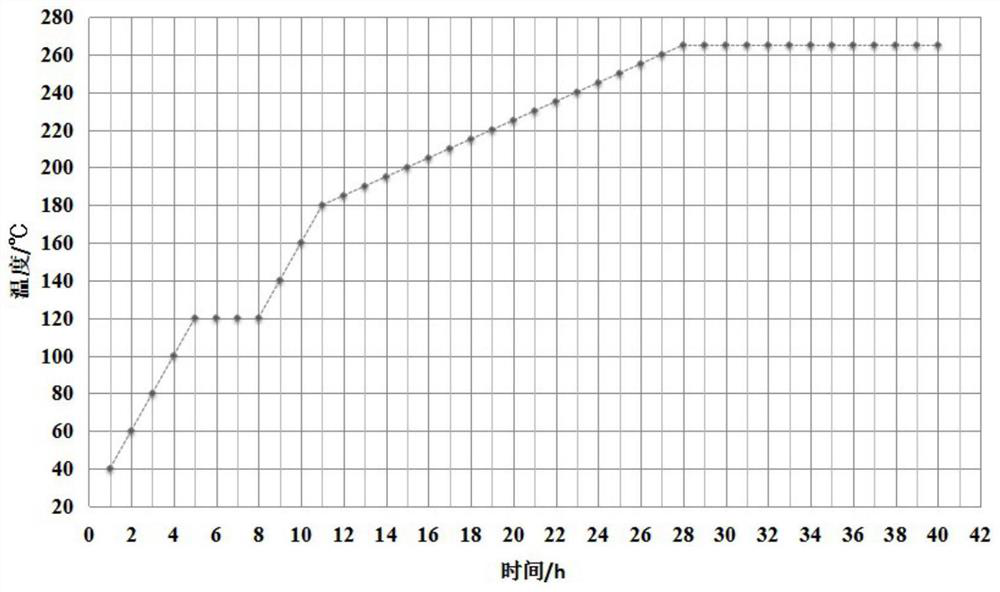

[0090] The operating process in the activation reactor 1 is: keep the feed gas circulation state, the superficial gas velocity (i.e. the inlet linear velocity) is 0.05m / s, and the Fischer-Tropsch synthesis iron-based catalyst with an average particle size of 5.0kg of 77 μm is first passed through nitrogen Transfer to the activation reactor 1, use the raw material gas to replace the inert gas in the reactor to below 0.1%, increase the pressure of the reactor to 1MPa, keep the superficial gas velocity of 0.05m / s, and start the temperature program of the activation reactor 1 , raised to 180°C at a rate of 10°C / heating; adjusted the superficial gas velocity to 0.9m / s, and raised to 265°C at a rate of 5°C / h; adjusted the superficial gas velocity to 0.05m / s, and maintained at 265°C After constant temperature for 12 hours...

Embodiment 3

[0095] The activation process is the same as in Example 1, except that the operating process in the activation reactor 1 is different.

[0096] The operating process in the activation reactor 1 is: keep the feed gas circulation state, the superficial gas velocity (i.e. the inlet linear velocity) is 0.05m / s, and the Fischer-Tropsch synthesis iron-based catalyst with an average particle size of 5.0kg of 77 μm is first passed through nitrogen Transfer to the activation reactor 1, use the raw material gas to replace the inert gas in the reactor to below 0.1%, increase the pressure of the reactor to 3MPa, adjust the superficial gas velocity to 0.4m / s, and start the temperature program of the activation reactor 1 , raised to 140°C at 10°C / heating rate, constant temperature for 4h; maintained superficial gas velocity 0.4m / s, raised to 180°C at 10°C / heating rate; adjusted superficial gas velocity to 2.0m / s, and °C / h heating rate increased to 270 °C; adjust the superficial gas velocity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com